Direct-flushing water-saving toilet seat

A flush-toilet technology, applied in flush toilets, water supply devices, flushing equipment with water tanks, etc., can solve problems such as complex structure of hydraulic opening devices, poor sealing effect of drain valves, and difficulty in opening sealing bowls, etc., to achieve Good for human health, good sealing effect, and clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

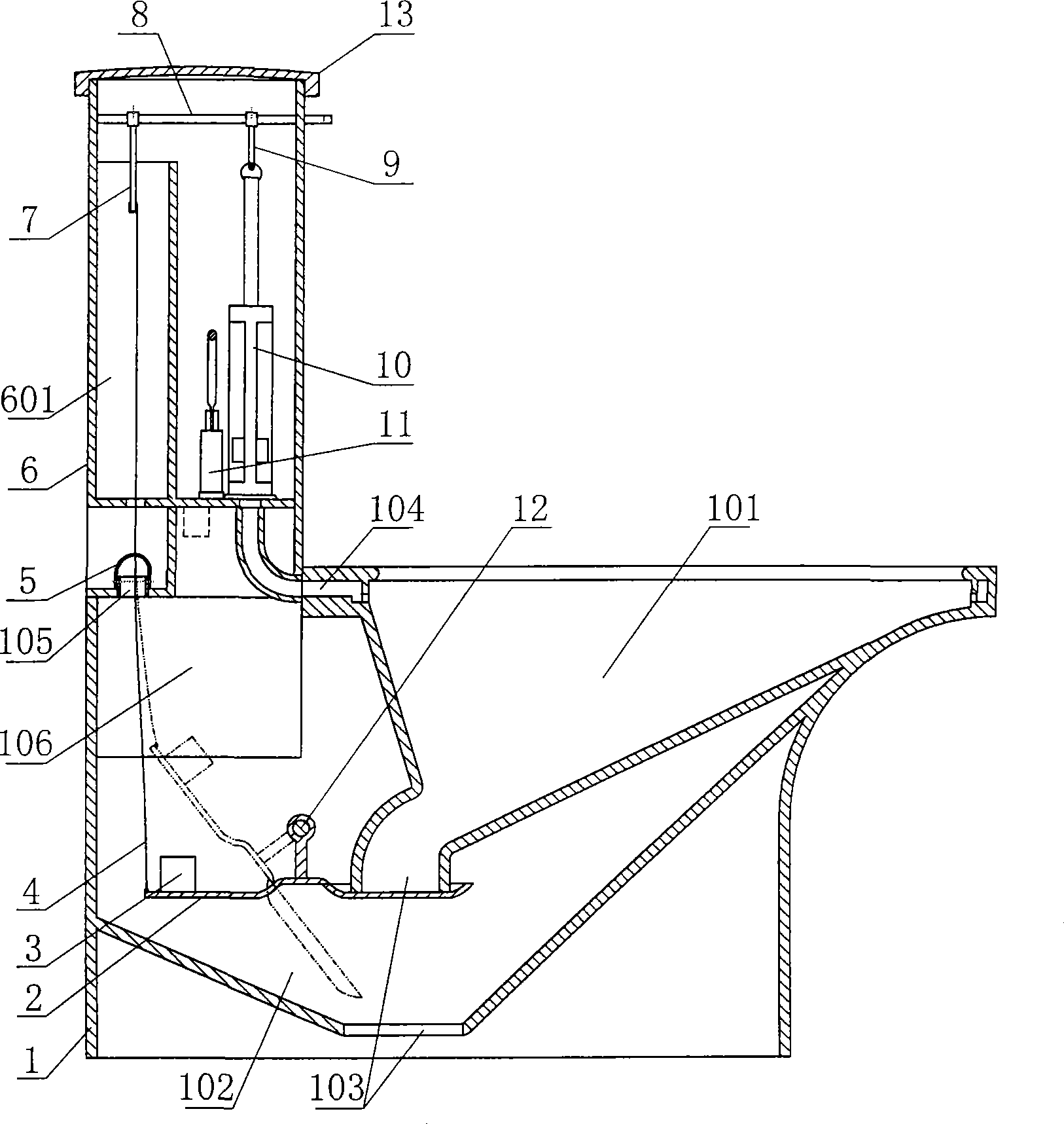

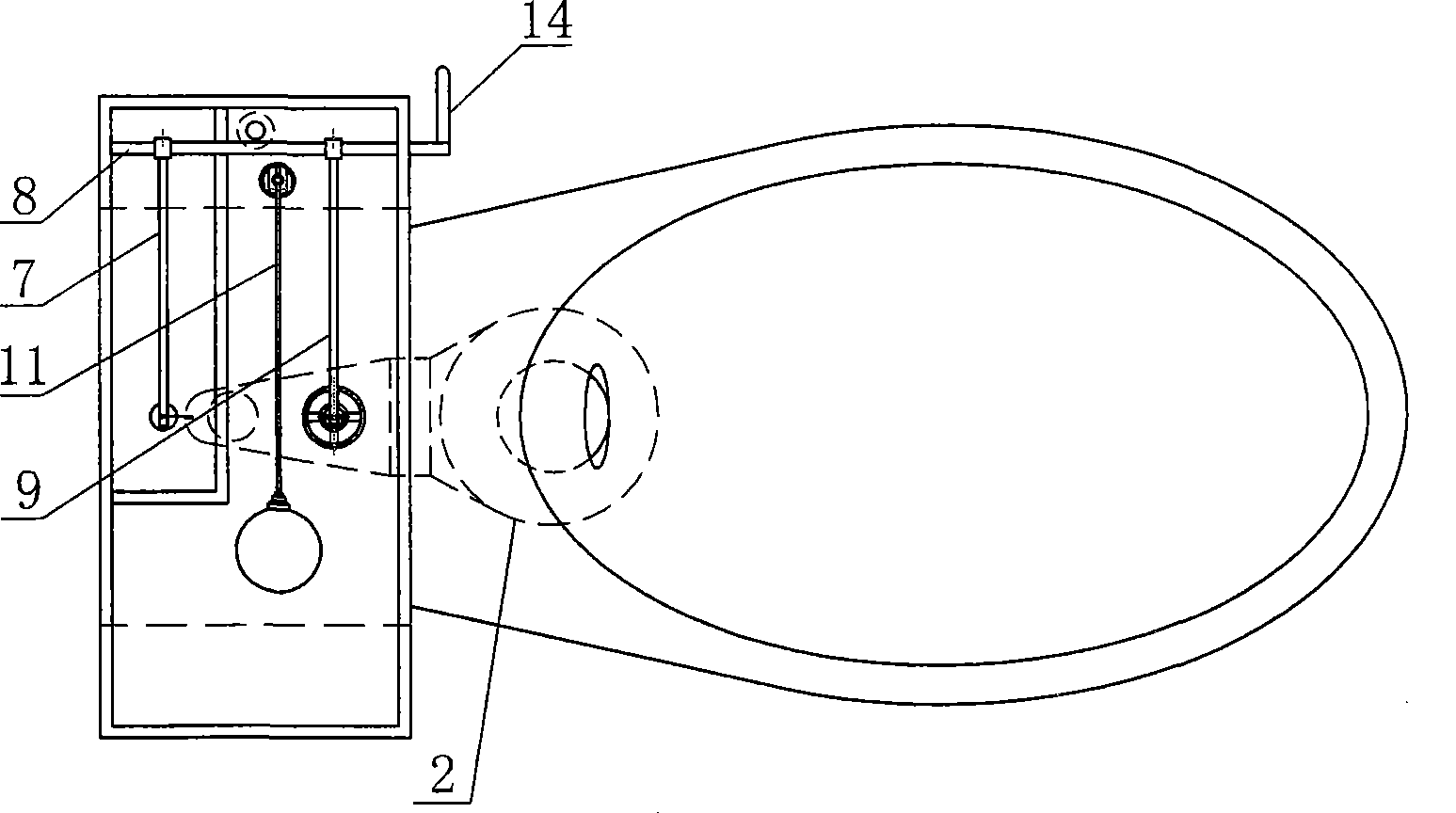

[0011] As shown in the figure, the present invention has a toilet body 1, and a water tank 6 integrated with the toilet body 1 is arranged at the upper end of the rear part of the toilet body 1, and a water supply control assembly 11 and a drain valve are installed in the water tank 6 10. An upper cover 13 is provided at the upper end of the water tank 6; the toilet body 1 is divided into a toilet receiving cavity 101 and an isolation cavity 102, and a flushing channel 104 is arranged in the upper port of the toilet receiving cavity 101, and the rear end of the flushing channel 104 is connected to the The drain outlet at the lower end of the drain valve 10 is connected, and the lower ends of the stool receiving chamber 101 and the isolation chamber 102 are respectively provided with opposite sewage outlets 103 . A long axis 12 runs across the isolation cavity 102 of the toilet body 1, and a sealing support plate 2 is hinged through the long axis 12 in the isolation cavity 102. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com