Dust bag structure easily fittable and connectable to a dust collector

a bag body and dust collector technology, applied in the field of dust collectors, can solve the problems of troublesome and inconvenient process, inconvenient use of resilient plates b>2/b> or spring clips, and inability to easily fit the bag body onto the collection tube of dust collectors, etc., and achieve the effect of convenient fittable and connectabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

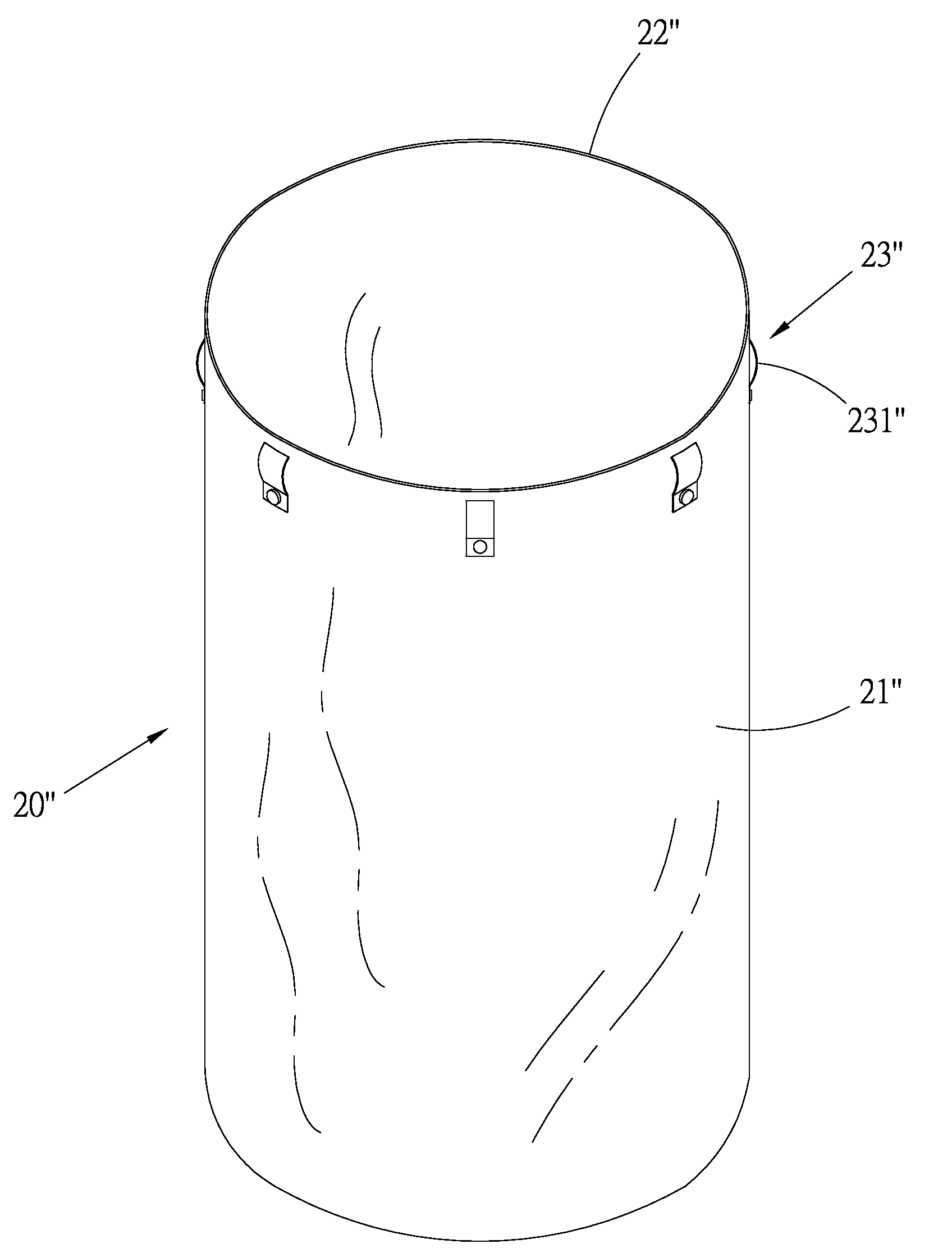

[0018]Please refer to FIGS. 3 to 6. According to a first embodiment, the dust bag structure 10 easily fittable and connectable to a dust collector of the present invention is composed of a dust bag 20 and a retainer member 30.

[0019]In this embodiment, the dust bag 20 is a soft bag-like body made of polyethylene. The dust bag 20 includes a soft bag body 21 having an open end 22 communicating an internal space of the bag body 21 with outer side thereof. The open end 22 is coaxially fitted on a collection tube 40 of a conventional dust collector. A hollow connection section 23 is positioned on outer circumference of the bag body 21 and extends along a periphery of the open end 22 in the form of an arc. In manufacturing, the connection section 23 is formed in such a manner that the original open end of the dust bag 20 is folded over itself with the endmost section fused with the outer circumference of the bag body 21 by means of thermal fusion or ultrasonic fusion. After folded, the new...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circumference | aaaaa | aaaaa |

| soft | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com