Modular freezer rack

a freezer rack and module technology, applied in the field of modules, can solve the problems of inconvenient storage, inconvenient storage, and bulky items in conventional freezer racks, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

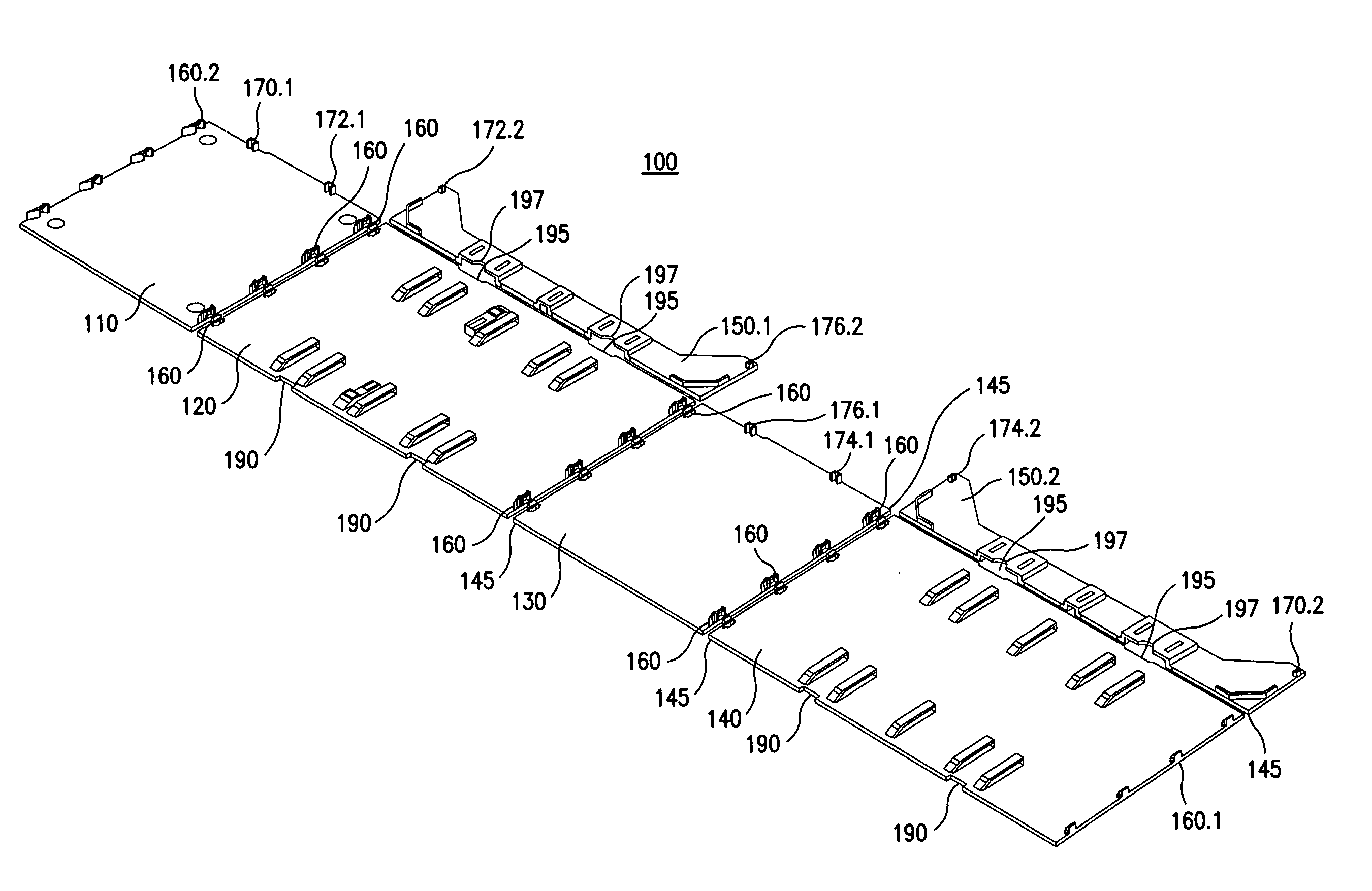

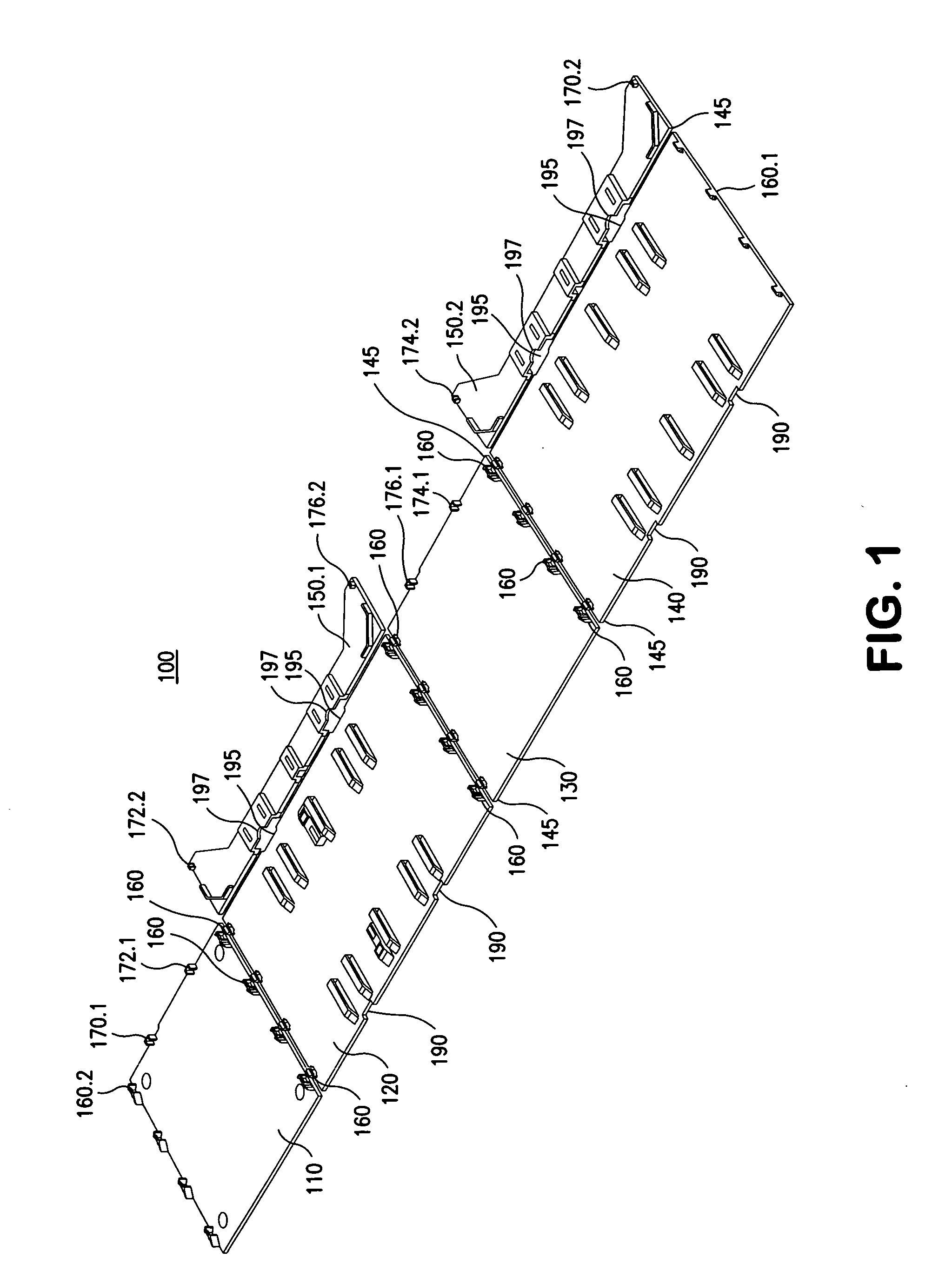

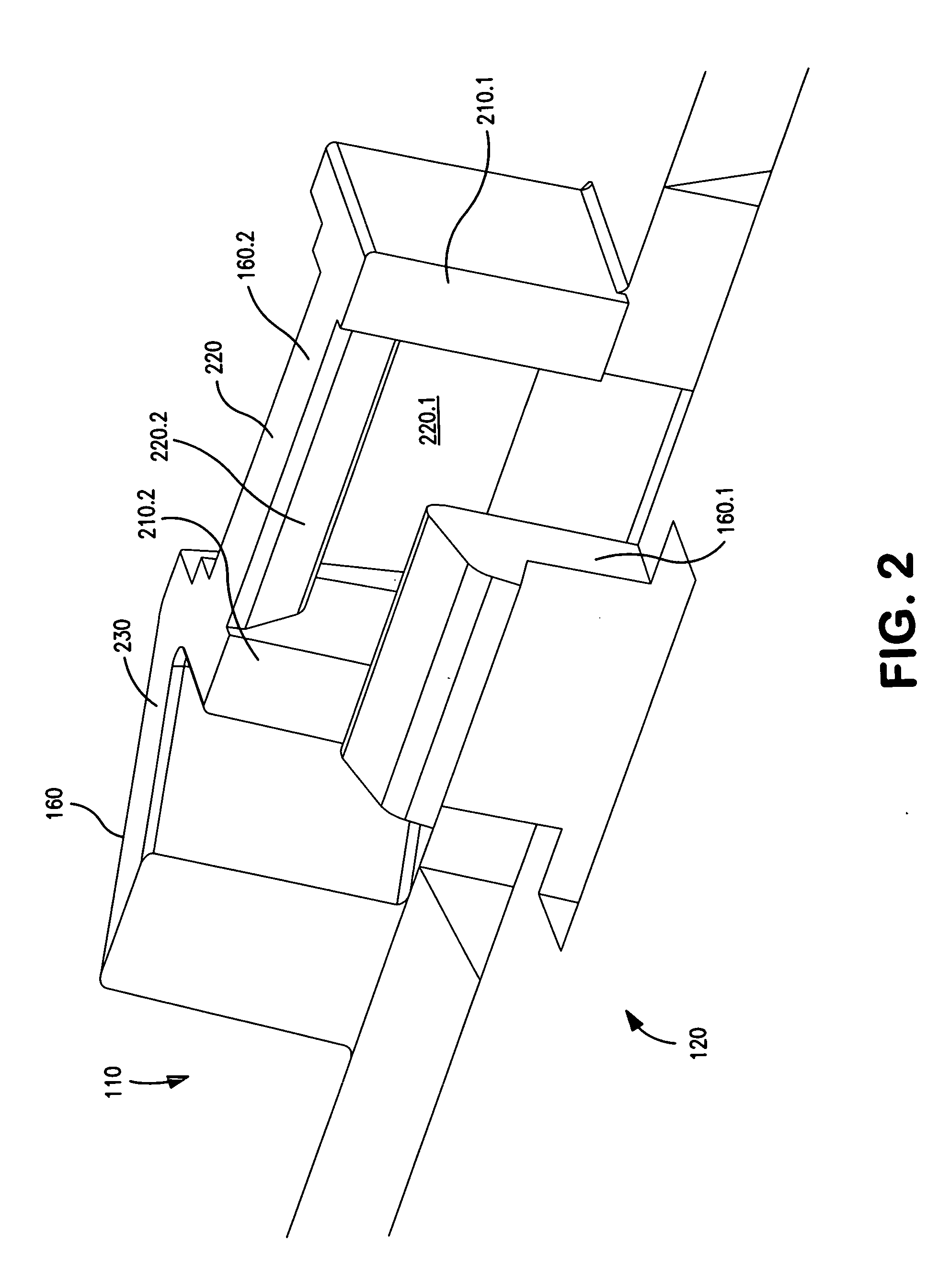

[0016]FIG. 1 illustrates an exemplary freezer rack 100 in accordance with a first, unfolded, state, including top member 110, first side member 120, bottom member 130 and second side member 140, which are linearly joined together. First side member 120 and second side member 140 each includes a back surface 150.1, 150.2 linearly joined at back edge of the first and second side members. Back surface 150.1, 150.2, preferably, are limited is size to create a back surface that is not fully closed. However, it would be appreciated that back surface 150.1, 150.2 may be sized to provide a fully closed back surface when the freezer rack 100 is in a second, folded, state. In the embodiment shown in FIG. 1, the bottom element 130 is positioned between and adjacent to the side elements 120, 140. However, it would be recognized that it may be possible to provide an embodiment of the invention wherein a top member 110 may be positioned between and adjacent to side members 140 and 120 or a side m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com