Method and apparatus for debanding a compressible bundle

a packaging band and compressible technology, applied in the field of compressible bundle debanding, can solve the problems of inefficiency of each manual process used to process the bundle, and the risk of automated processing of some bags, so as to achieve the effect of not risking damage to the bundl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

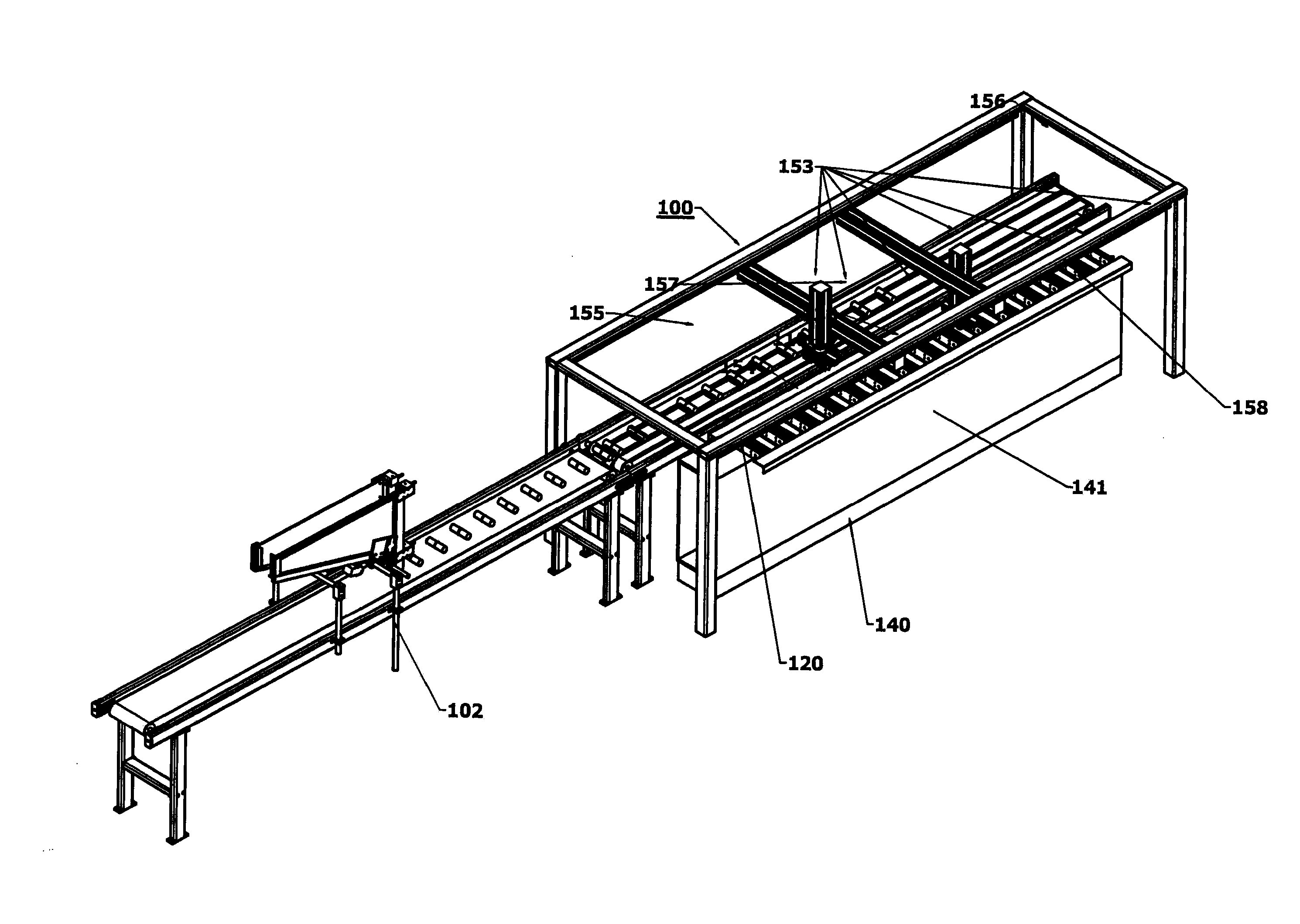

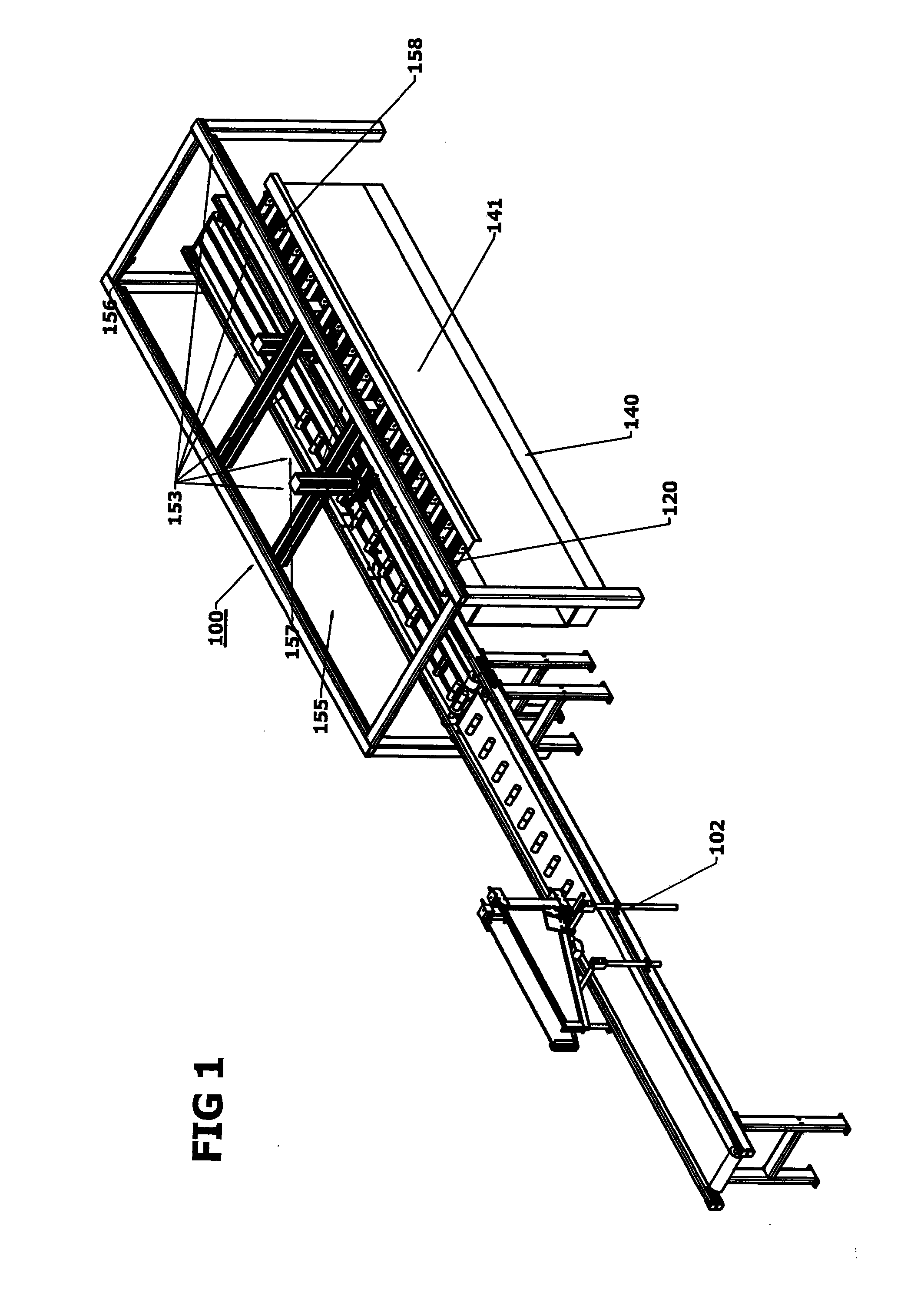

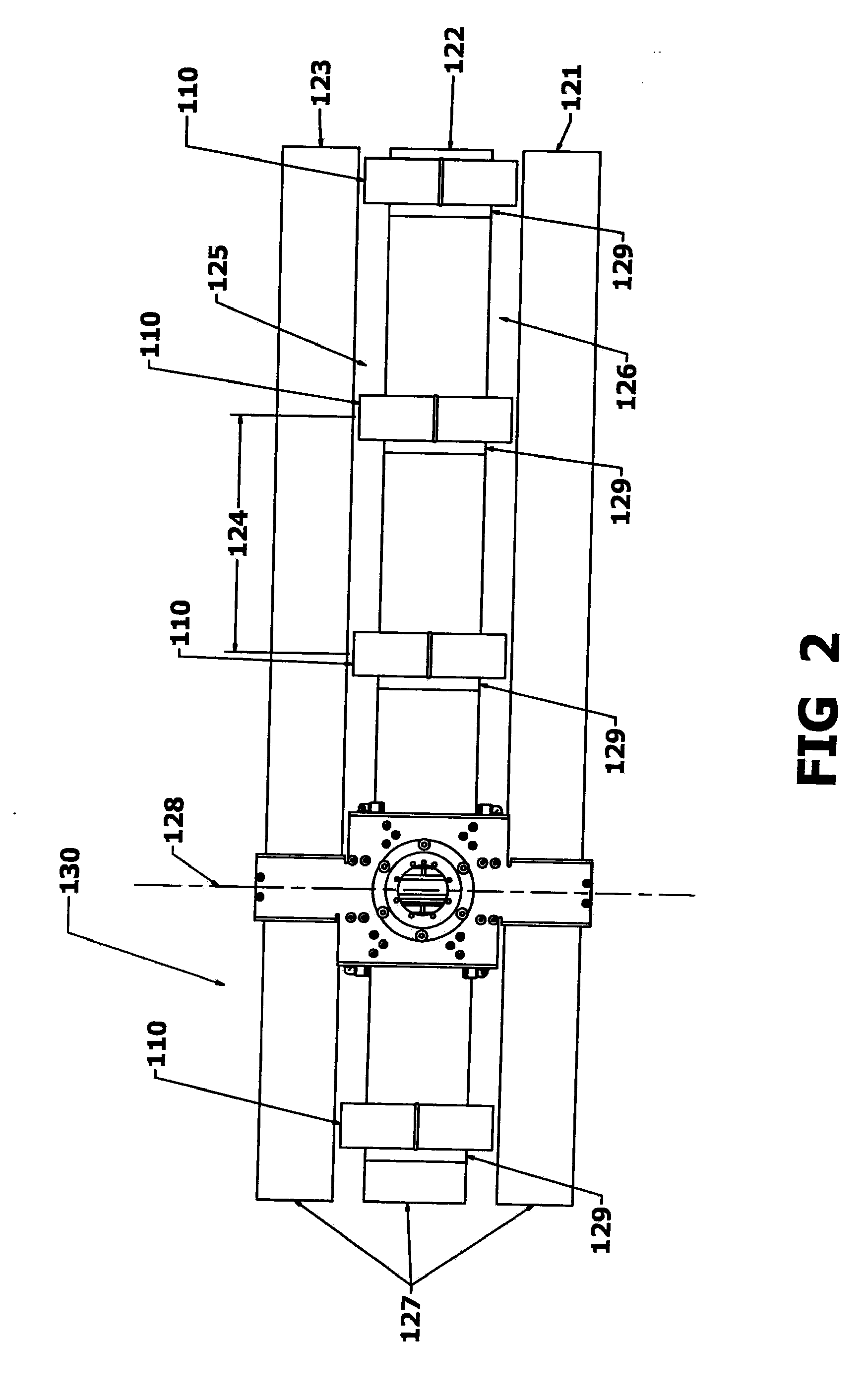

[0029]The present invention is directed to a method and apparatus for debanding a compressible bundle, and in particular, for debanding a compressible bundle of bags (for example, polyethylene bags) which are banded (for example, with paper bands, rubber bands, polyethylene bands, or bands comprising any of a variety of other conventional band materials).

[0030]In a preferred embodiment of the invention, bundles of bags are arranged in a single-file grouping along a moving direction of a debanding conveyor line. Each bundle of bags is secured by a band that circumferentially surrounds a portion of the bundle. The bundles may be manually provided to the conveyor line, or may be provided to the debanding conveyor line by an intake system including a hopper that receives and sorts the bundles of bags before depositing the bundles either onto the debanding conveyor line, or onto accumulator conveyor line that is configured to accumulate and transfer the bundles to the debanding conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com