Attaching Device for End of Spring

a technology for fixing devices and end springs, which is applied in the direction of rod connections, manufacturing tools, chairs, etc., can solve the problems of increasing the cost of retainers and producing noise, and achieve the effect of preventing noise from being generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

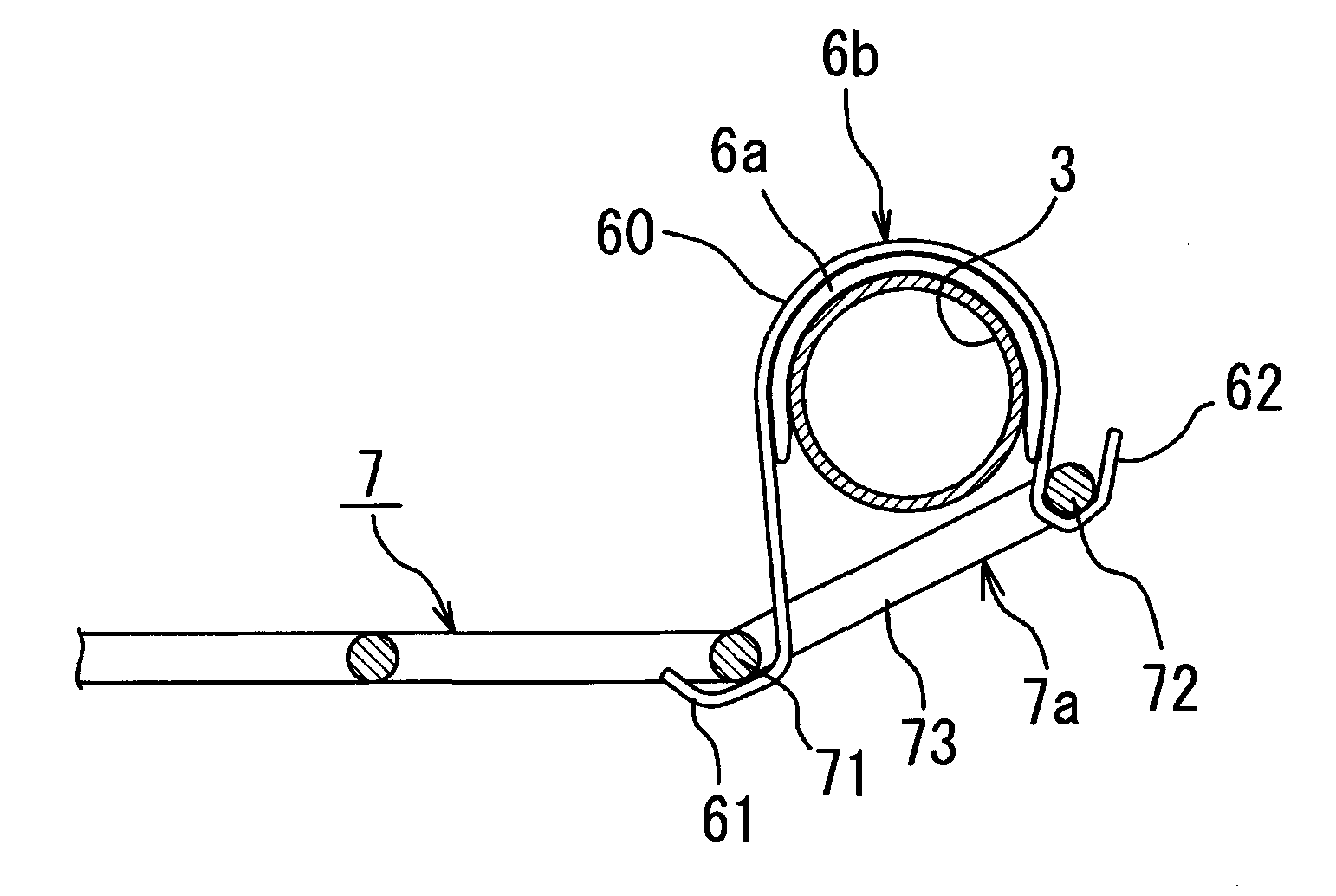

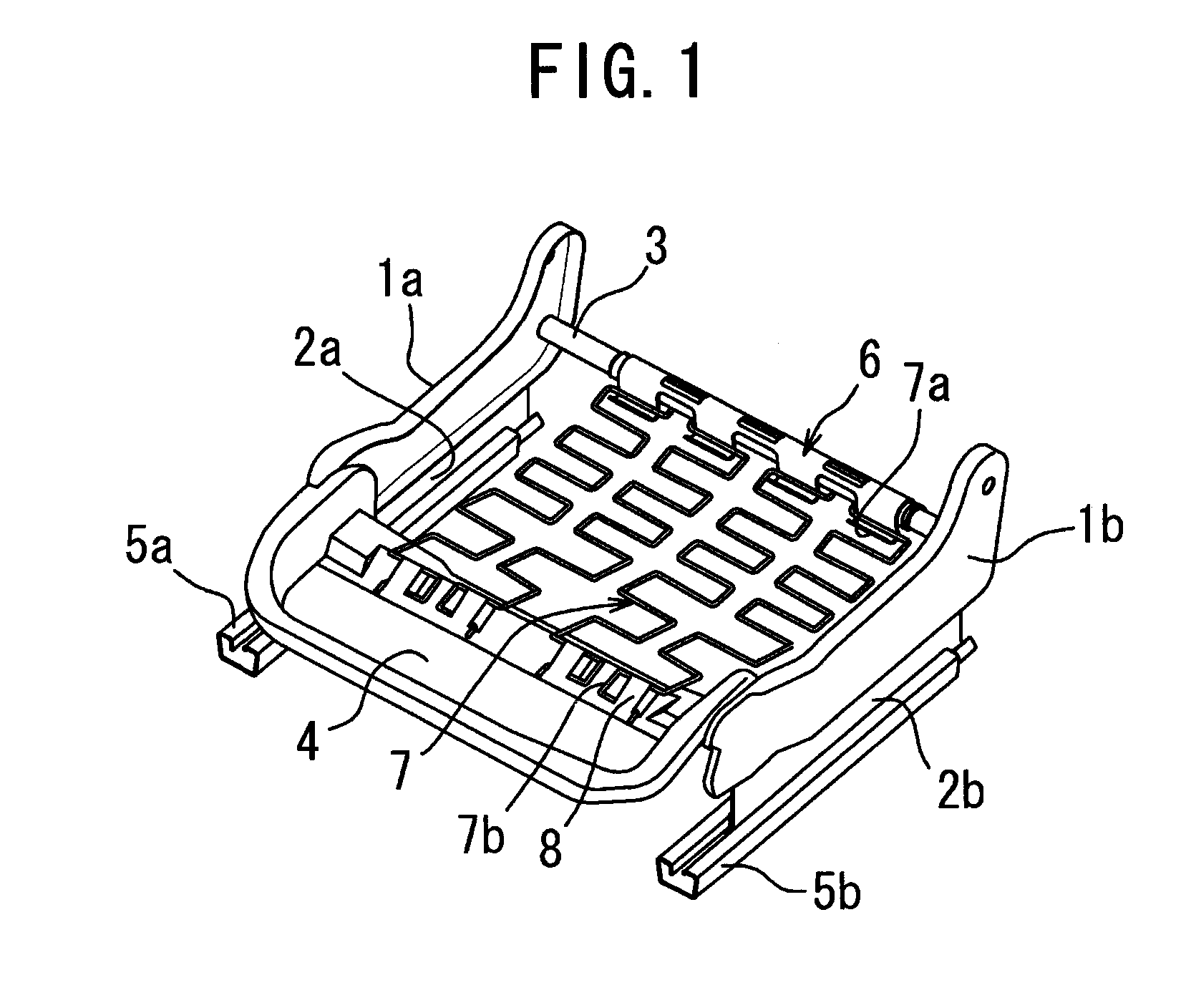

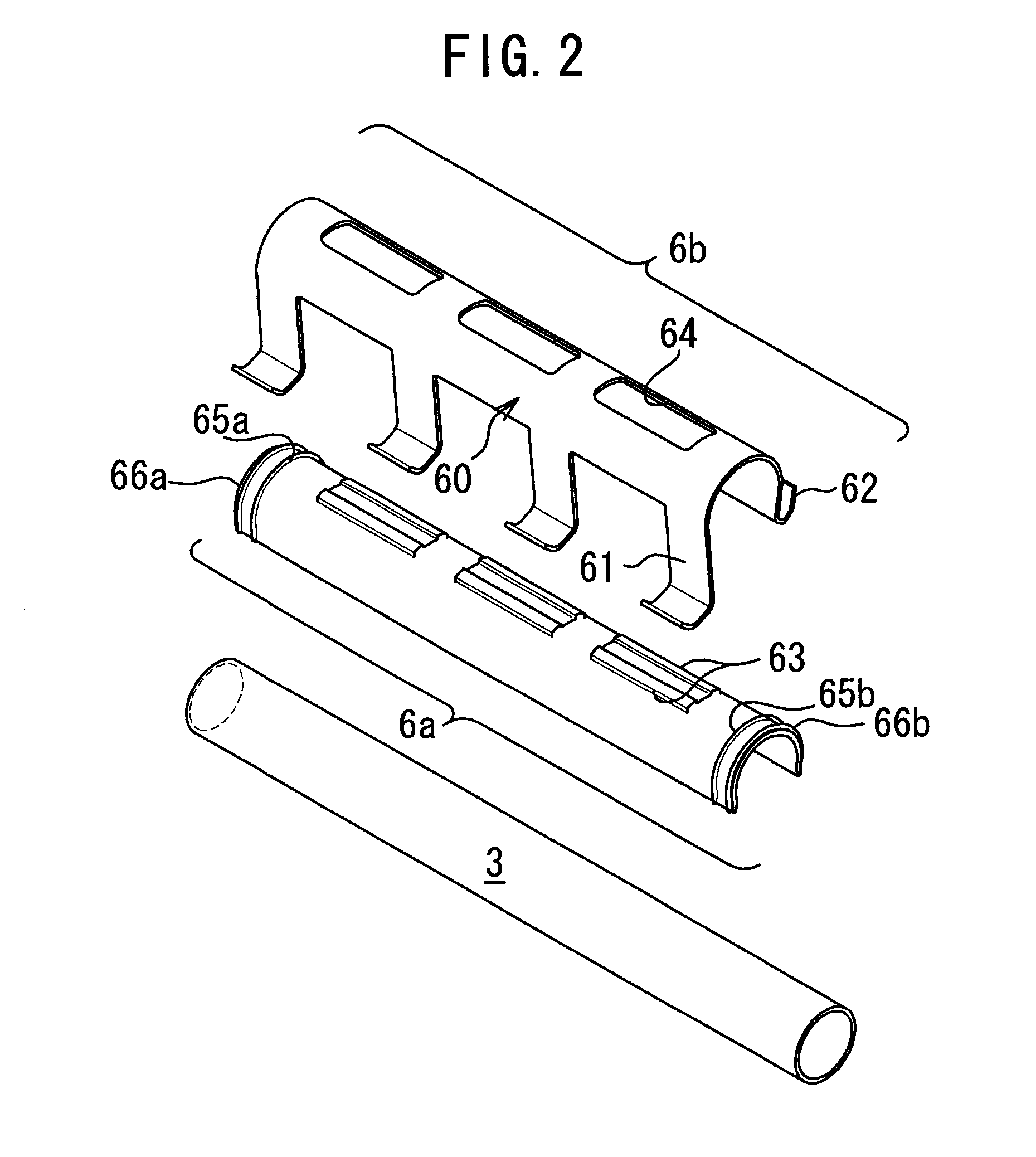

[0021]Referring to FIG. 1, there is illustrated a seat cushion frame for a slide-type vehicle seat, in which springs are employed as means to support a cushion for a seat cushion of the vehicle seat and fixed at end portions thereof to the seat cushion frame by an attaching device 6 for fixing end portions of springs according to an embodiment of the present invention. The seat cushion frame comprises a pair of spaced apart left and right side frame sections 1a, 1b, a pair of spaced apart upper rail members 2a, 2b integrally attached to the side frame sections 1a, 1b, a round shaft 3 formed from a round pipe or round rod, the round shaft 3 being attached between rear end portions of the side frame sections 1a, 1b, and a pan frame member 4 attached between forward end portions of the side frame sections 1a, 1b. In FIG. 1, reference numerals 5a, 5b denote lower rail members to which the upper rail members 2a, 2b are slidably supported.

[0022]In the seat cushion frame, a plurality of sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com