Method for the fabrication of a screw member for plate member fastener

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

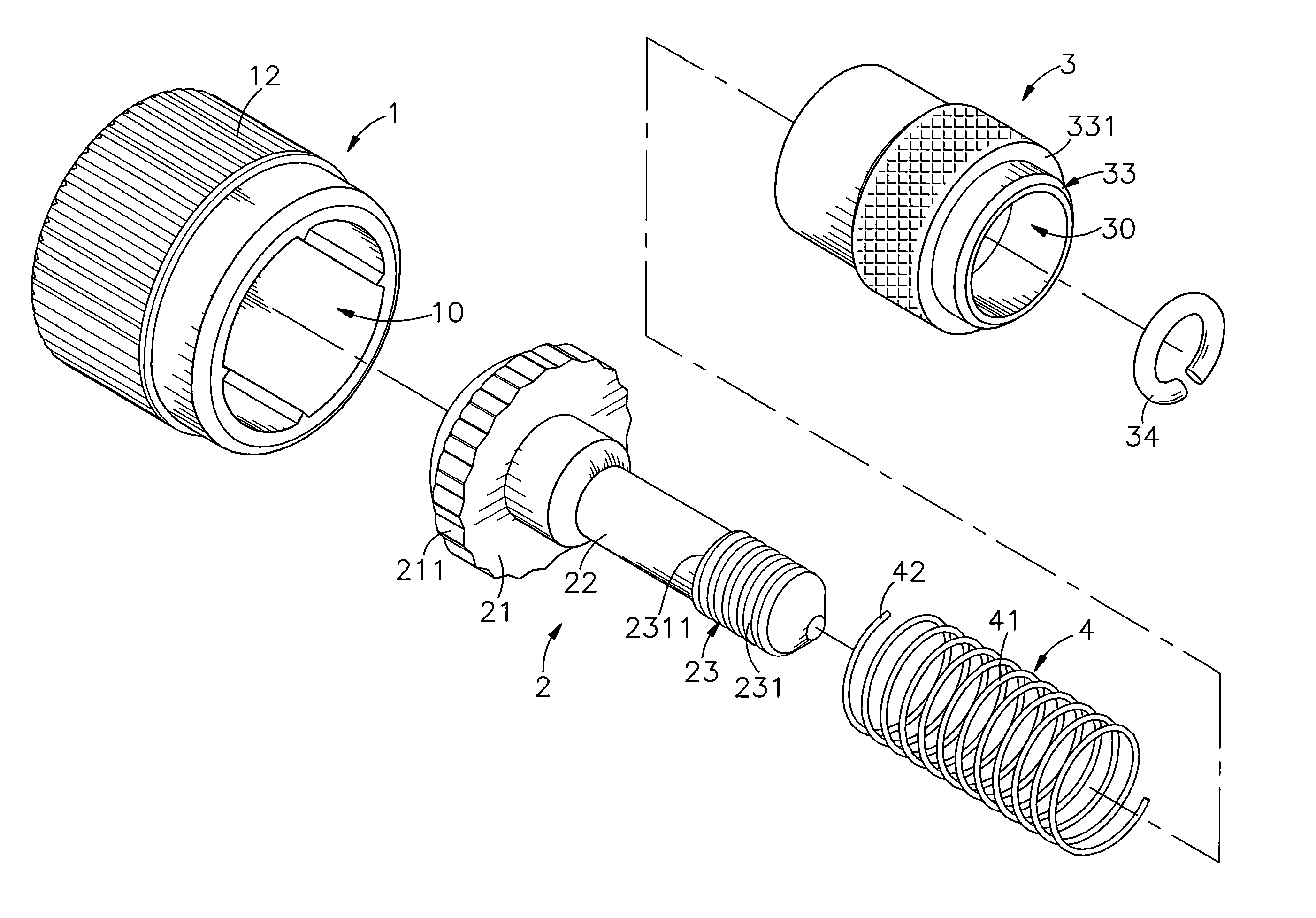

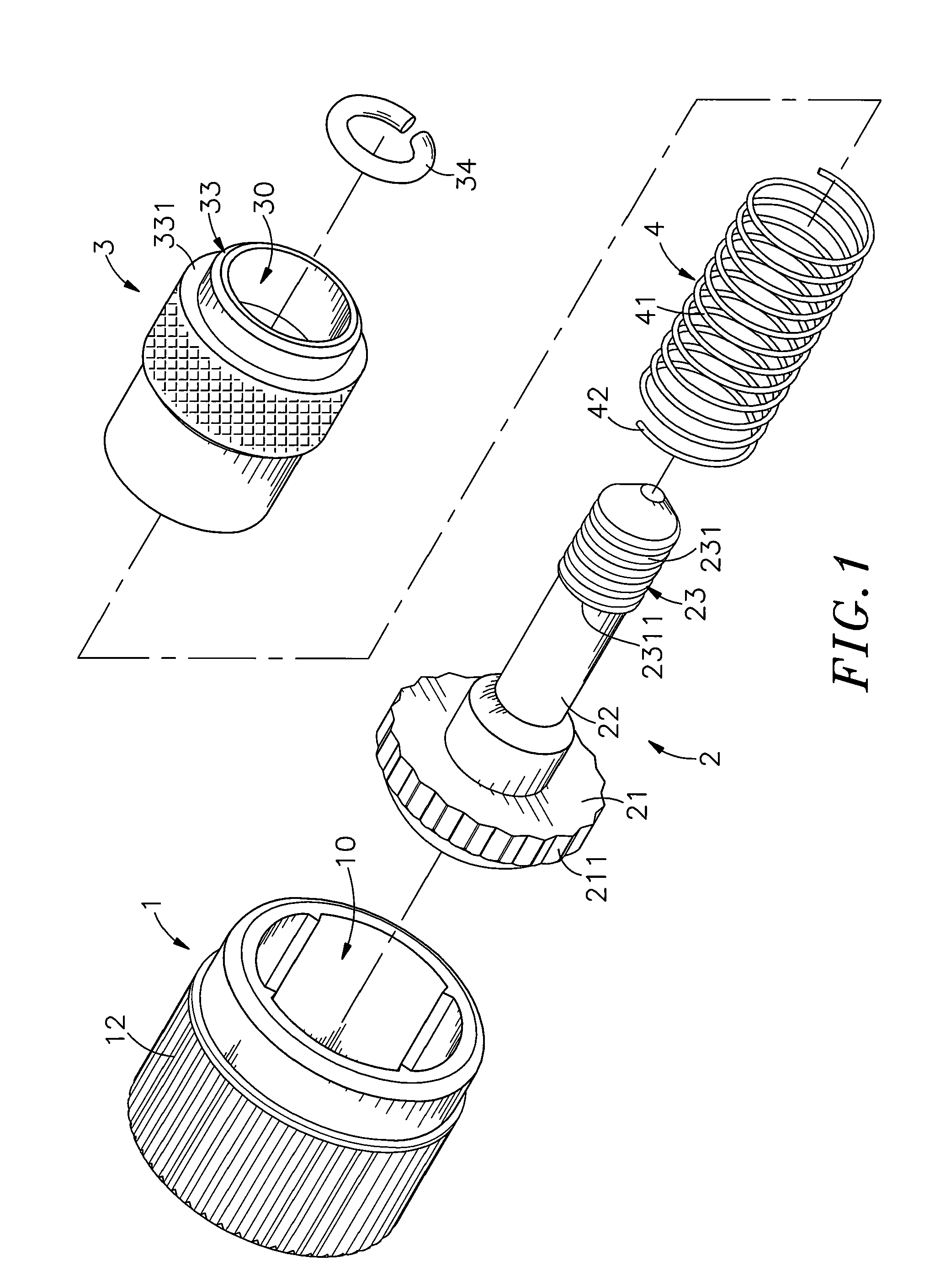

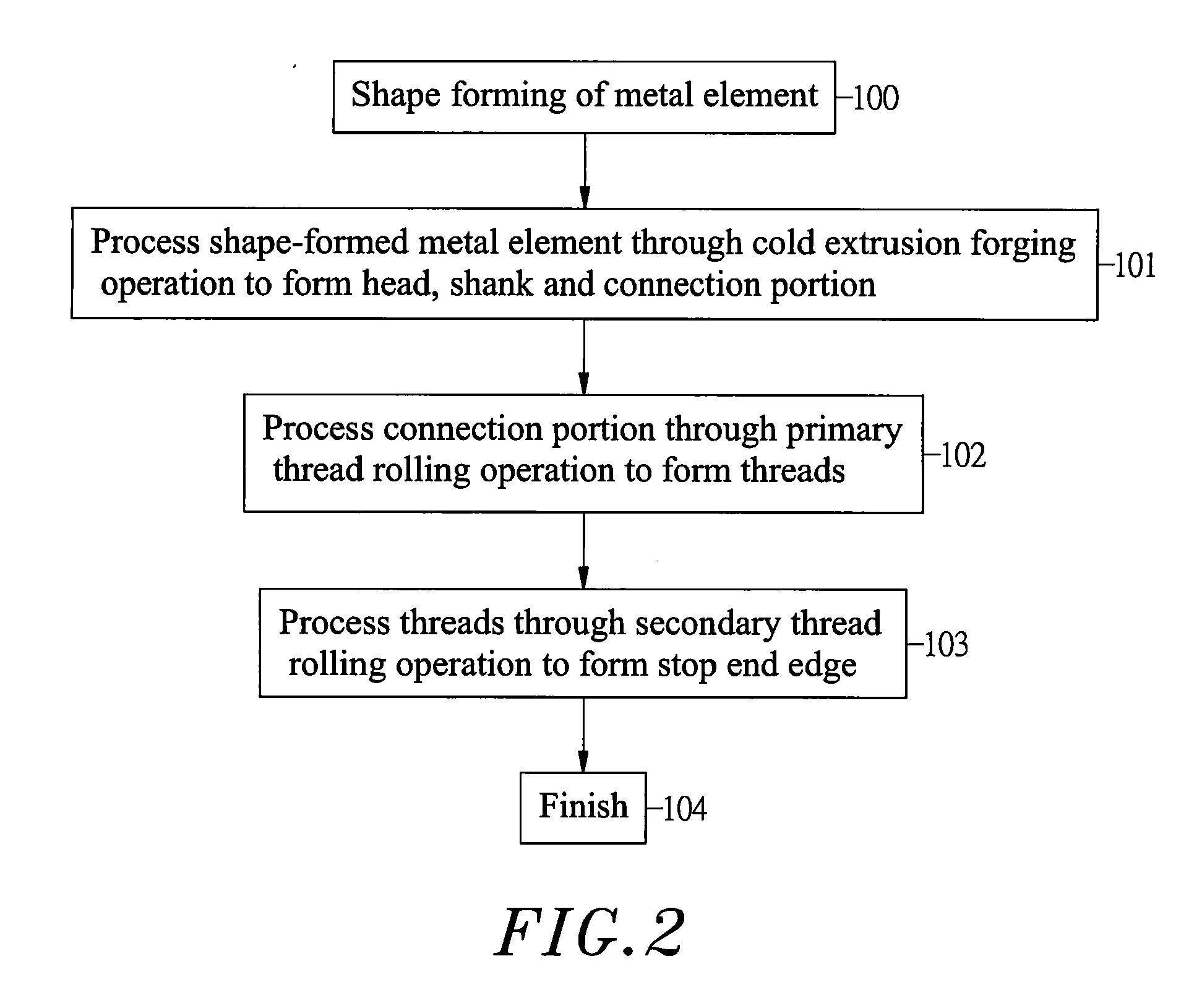

[0021]Referring to FIGS. 1 and 7, a plate member fastener in accordance with the present invention comprises a cap 1, a screw member 2, a barrel 3, and a spring member 4.

[0022]The cap 1 is a hollow member having a center opening 10 axially extending through the top and bottom sides for receiving the barrel 3, the screw member 2 and the spring member 4, a serrated inside retaining portion 11 arranged around the inside wall near the top side for retaining the engagement portion 211 of the screw member 2, and a grip 12 located on the periphery at the top side for gripping by hand.

[0023]The screw member 2 is a metal member having a head 21, an engagement portion 211 formed on the periphery of the head 21 for engagement with the serrated inside retaining portion 11 of the cap 1, a shank 22 perpendicularly extended from the center of the bottom wall of the head 21 and terminating in a connection tip 23, threads 231 spirally arranged around the periphery of the connection tip 23 and defini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Proximity effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com