Venting System for Sports Helmets

a technology for sports helmets and venting systems, applied in headwear caps, hats, motor sports, etc., can solve the problems of increased risk of injury, complex construction with respect to manufacture, and inability to control the supply of air stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

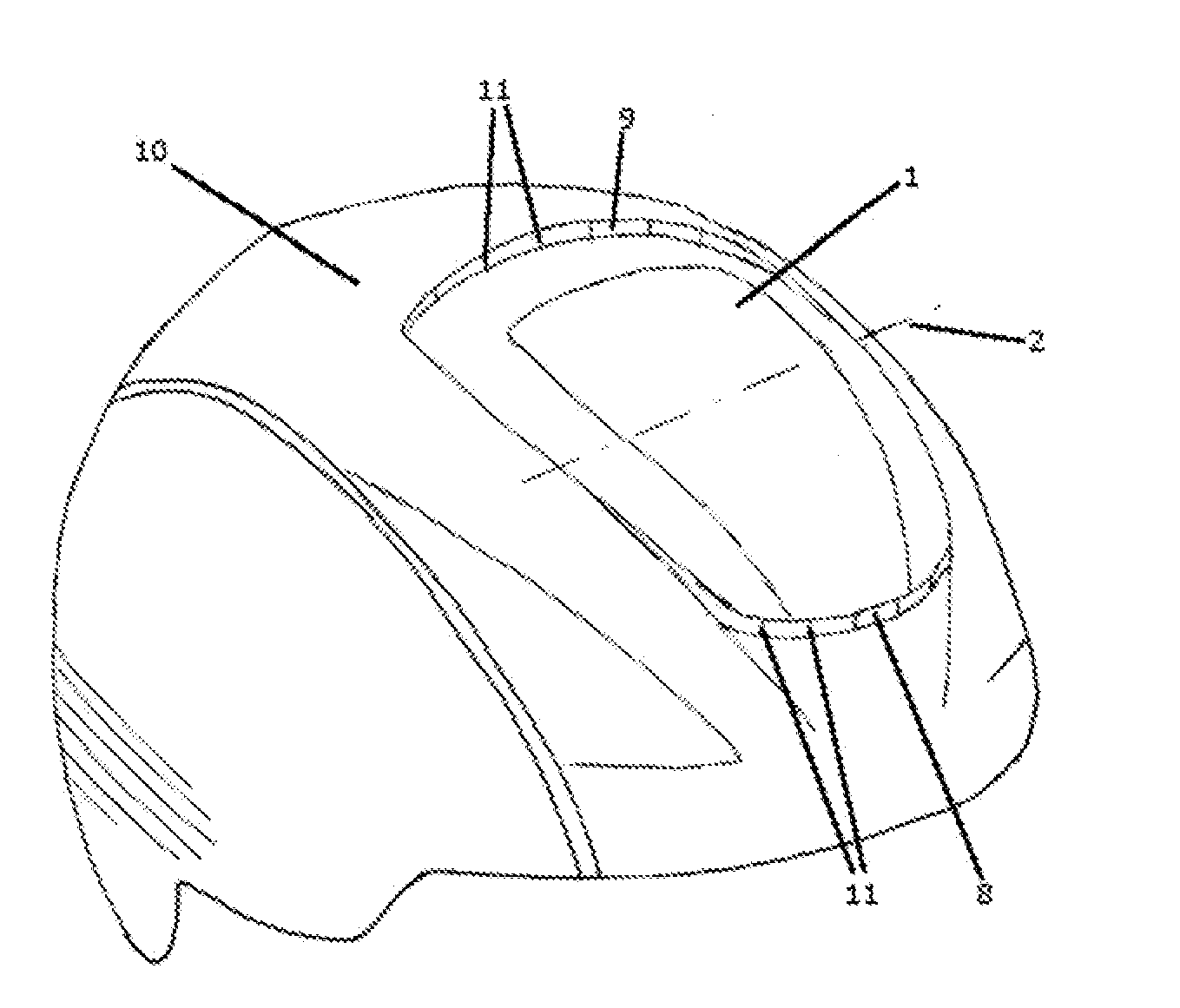

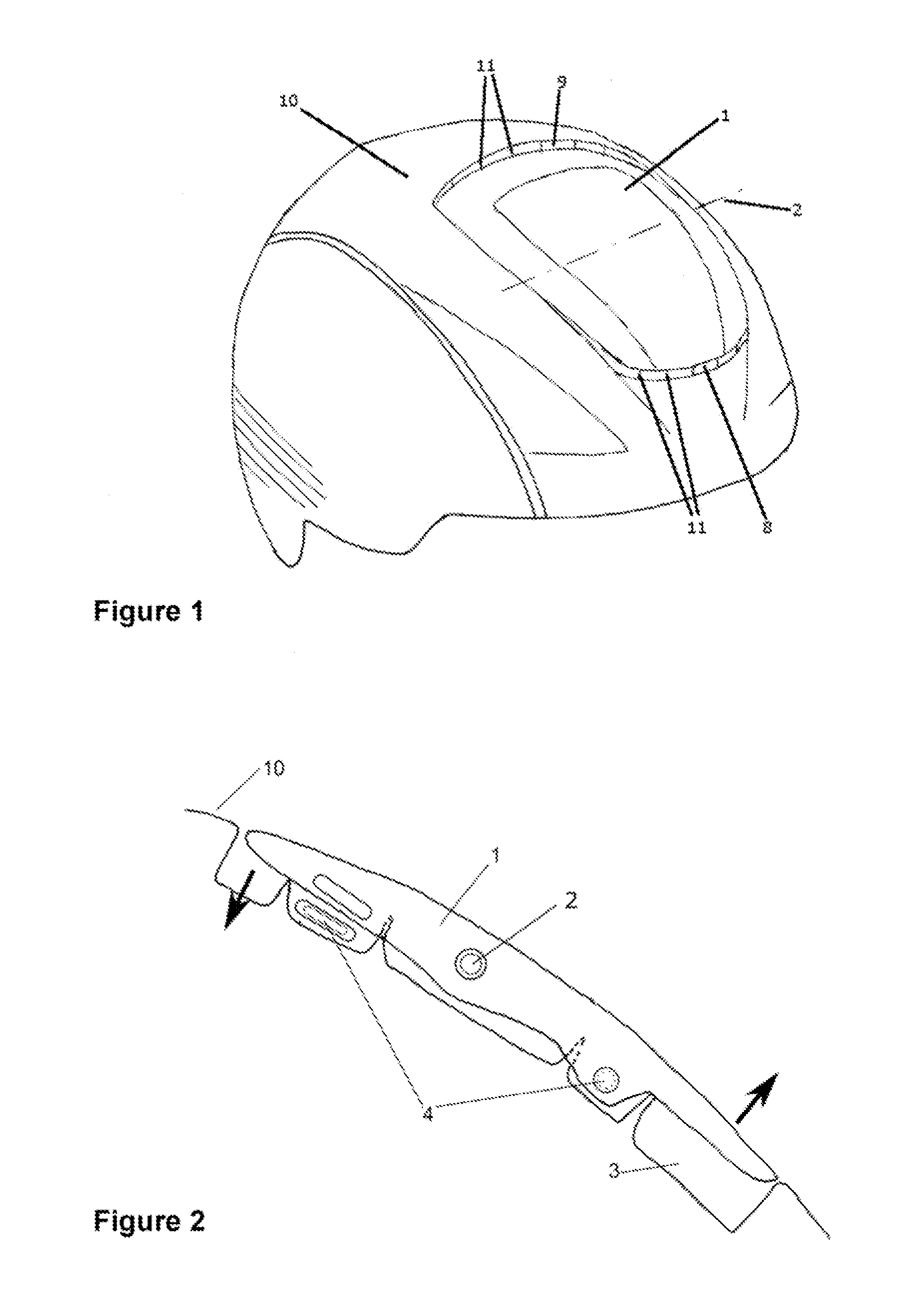

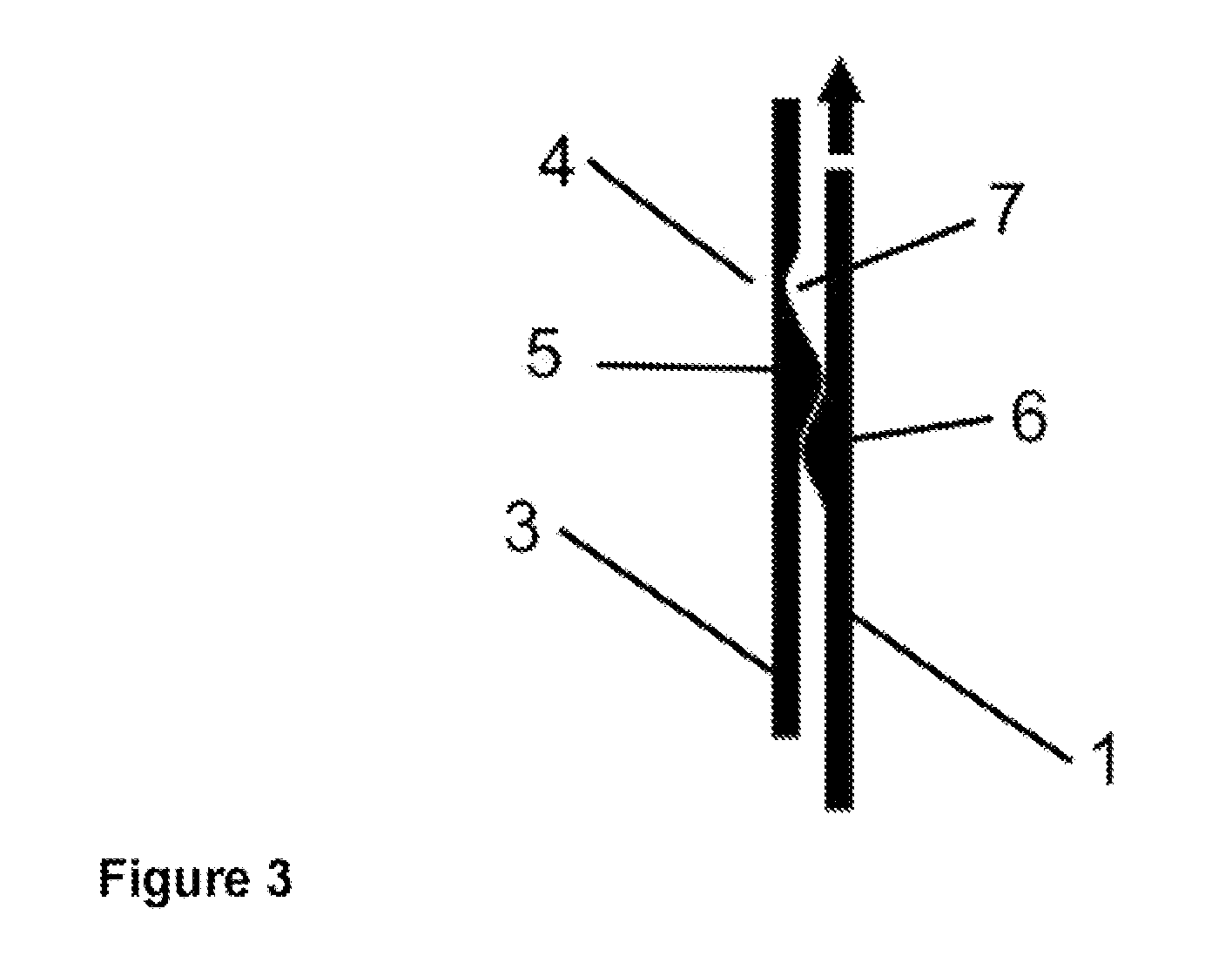

[0029]In one embodiment, two venting openings are provided in a helmet. Both venting openings are arranged along a symmetry line that extends from the forehead area of the helmet (root of the nose of the wearer) across, during wearing, the highest point toward the neck area (cervical vertebra of the wearer) of the helmet. The first venting opening is located above the forehead area of the helmet in front of the highest point, the second venting opening is located behind the highest point of the helmet in front of the neck area. The two openings are axial-symmetrical to the above-mentioned symmetry line and are provided with covers. The covers are integrated in such a way into the helmet surface that in the closed state they are flush with its surface. The covers are moveable and can partially release the venting openings by tilting. The axis of rotation of the cover extends centrally and at a right angle to the symmetry line.

[0030]Upon actuation of the forward cover, the front end, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com