Battery module, method of fabricating the same, and vehicle having battery module

a battery module and battery technology, applied in the field of battery modules, can solve problems such as deterioration in cycle life performance, and achieve the effect of excellent cycle life performance and long service li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

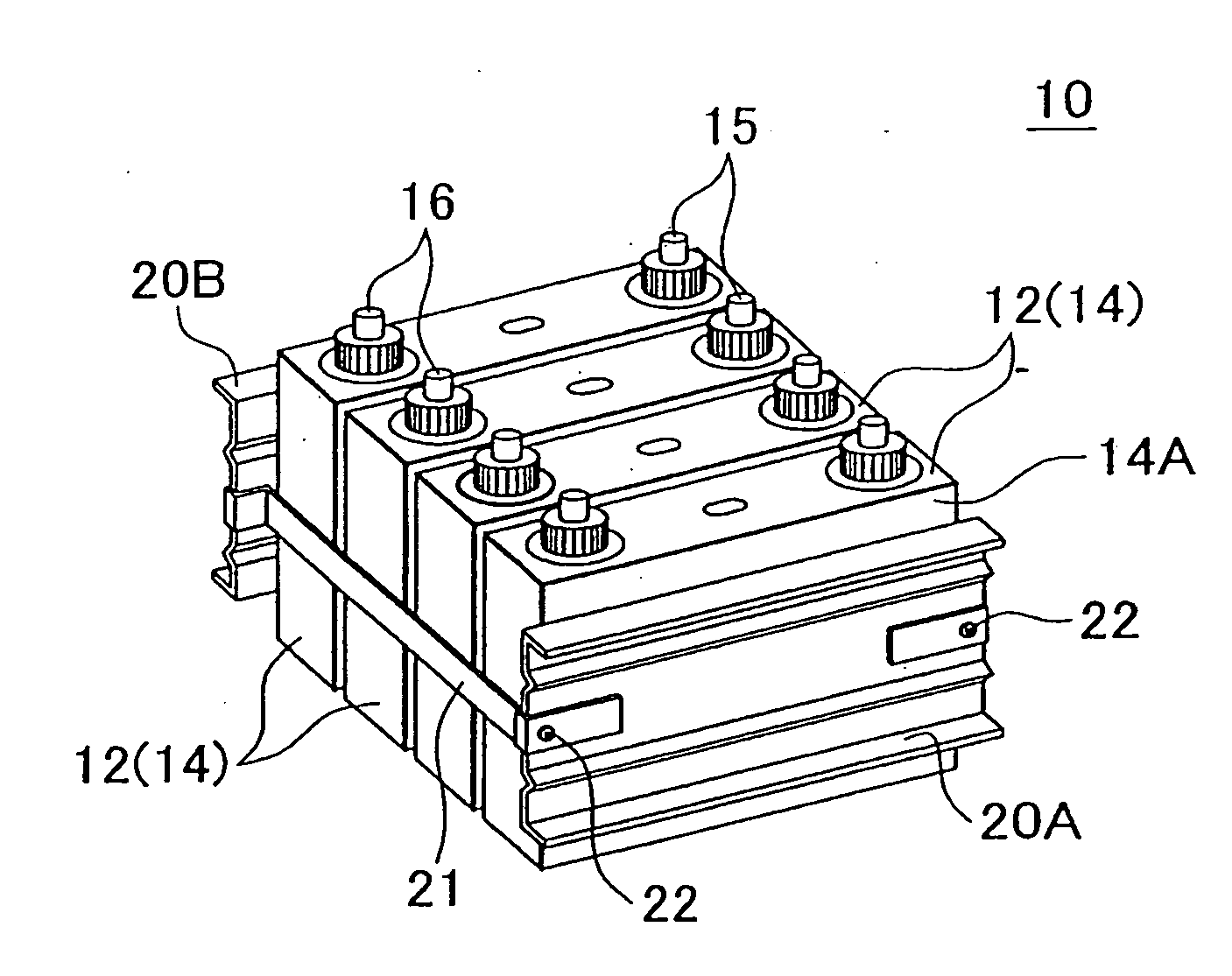

Image

Examples

Embodiment Construction

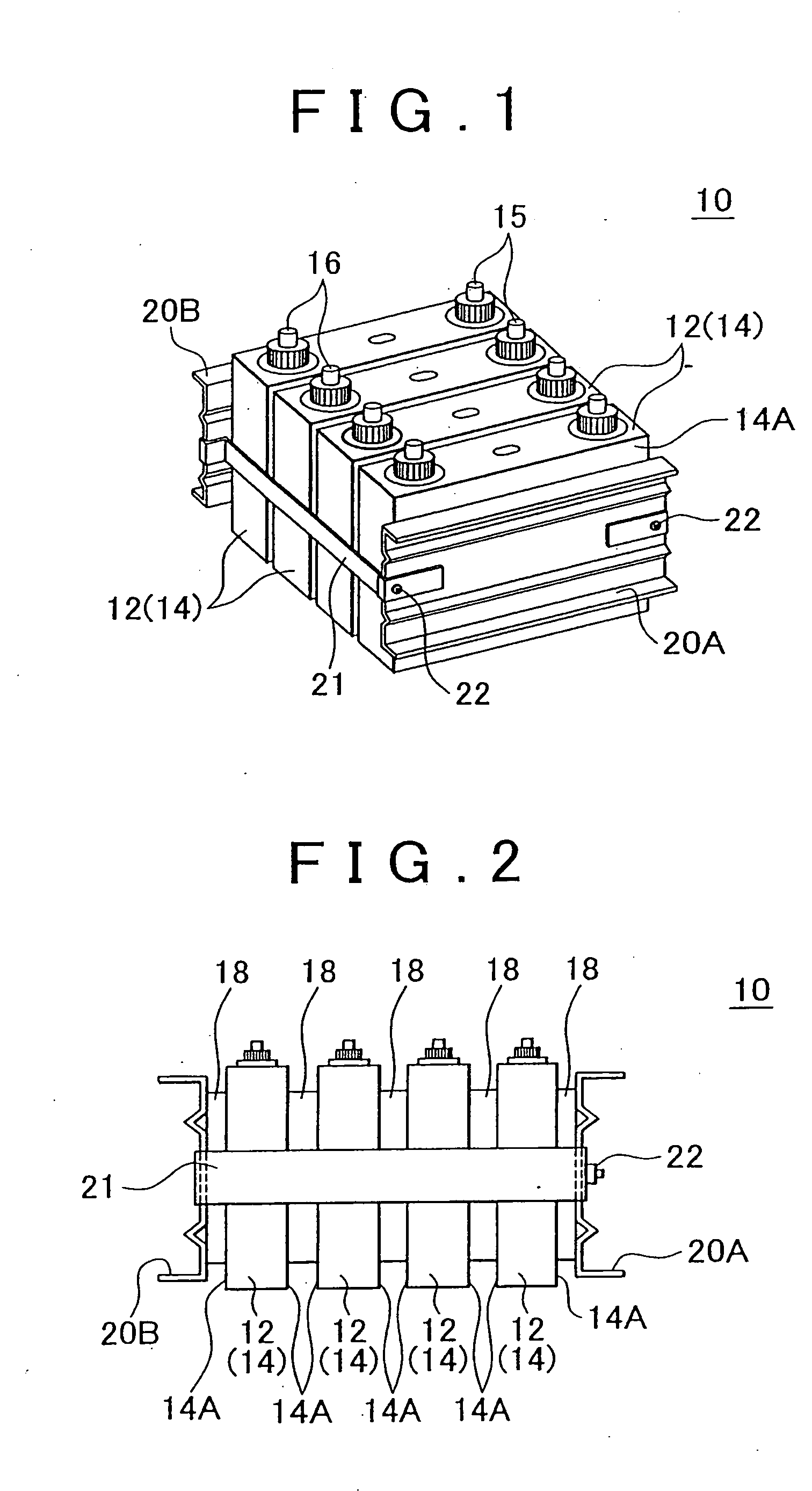

[0031]In the following, one exemplary embodiment of the invention will be described. It is to be understood that matters (such as the construction of positive and negative electrodes and separators and methods of fabricating the same, method of restraining battery cells, and a method of installing a battery module on a vehicle) necessary to practice the present invention, other than matters (such as the construction of cells that constitute the battery module, the construction of a rolled electrode body and a method of fabricating the rolled body) particularly mentioned in this specification, can be regarded as design matters that are obvious to those skilled in the art and are based on the related art in the technical field concerned. The present invention can be practiced on the basis of the content of this specification and common technical knowledge of the field concerned. The battery module according to the invention has excellent cycle life performance and achieves long servic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com