Acoustical and firestop rated track for wall assemblies having resilient channel members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

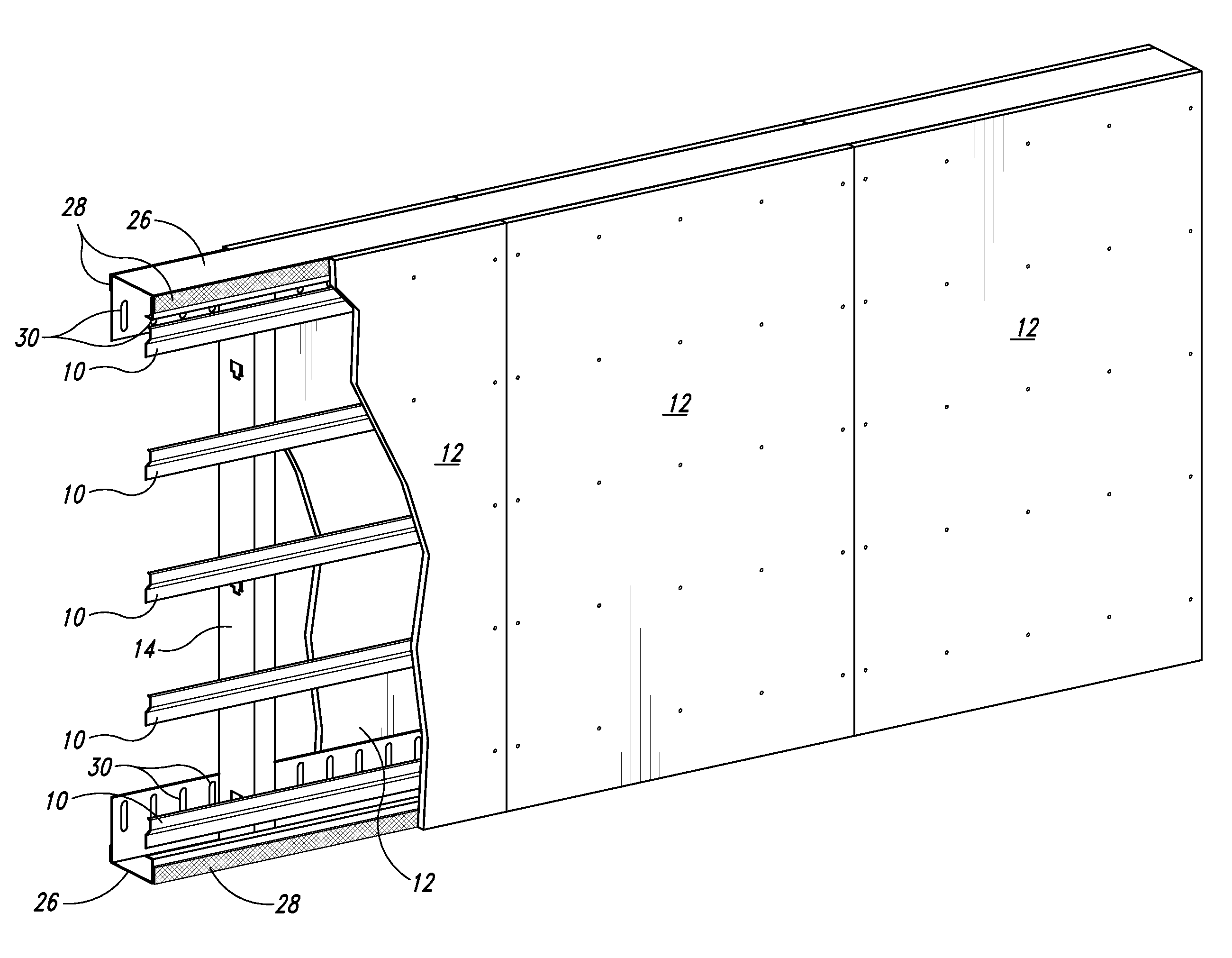

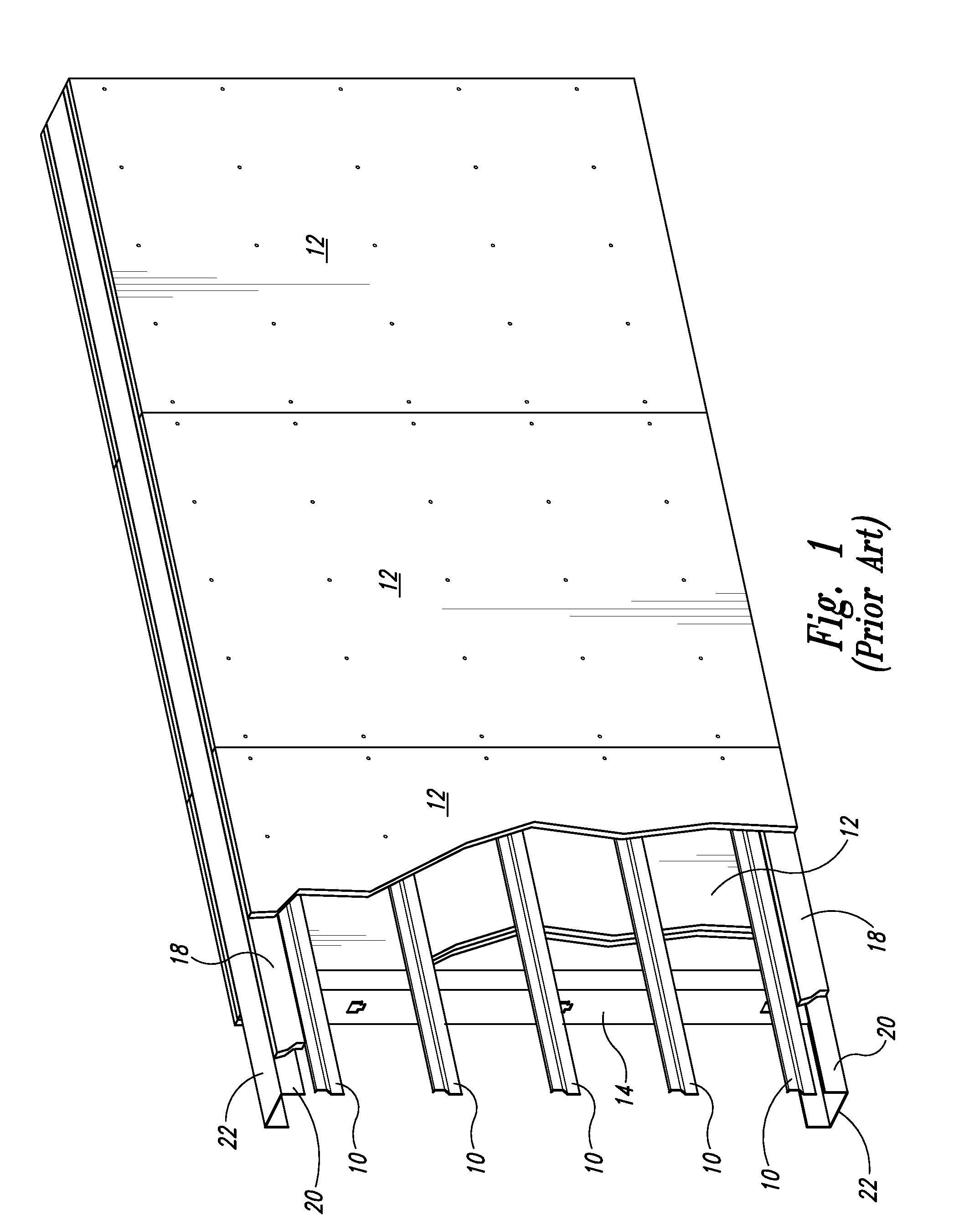

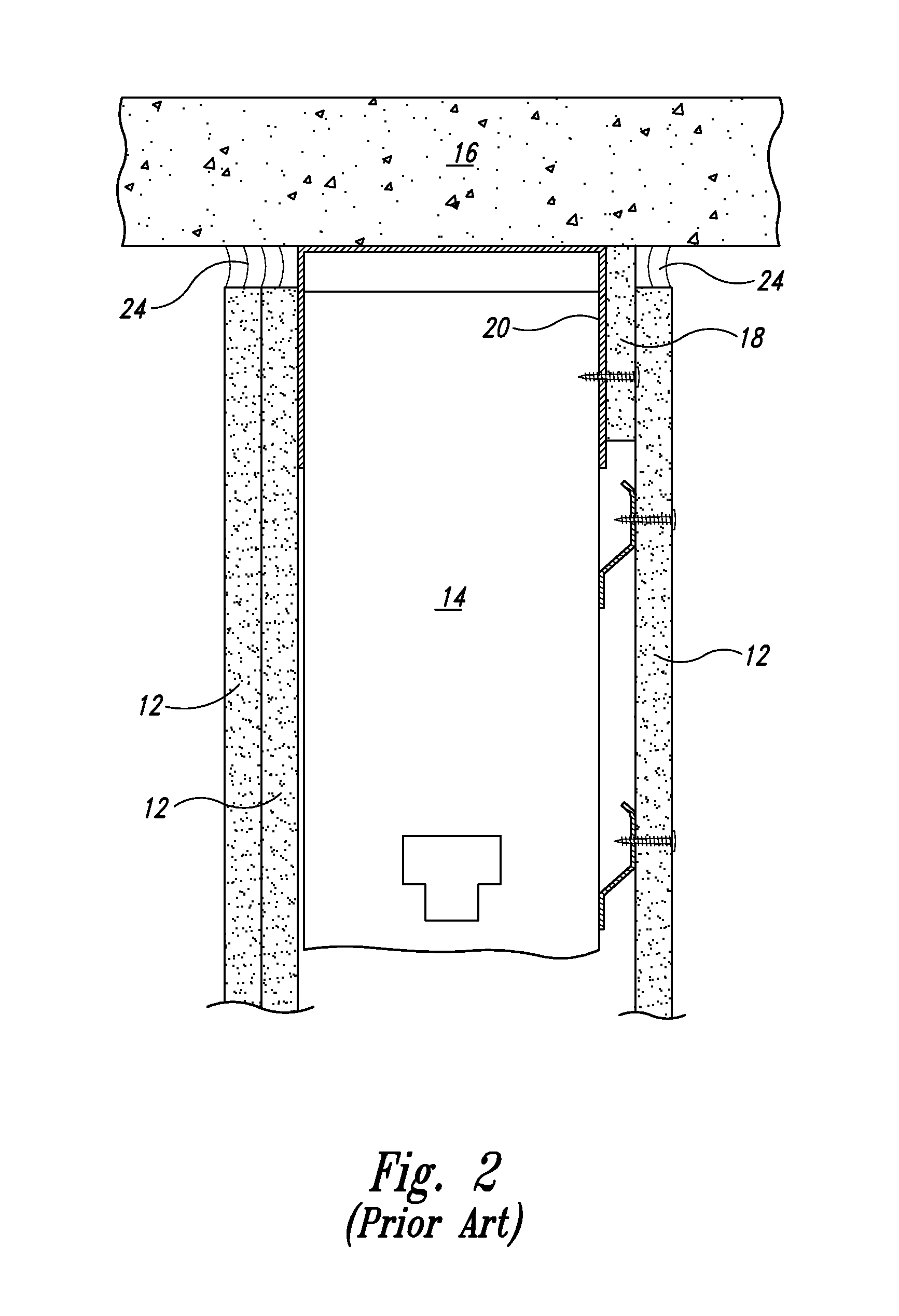

Image

Examples

example 1

[0029]A mock-up of a sound dampening and fire retardant wall assembly in accordance with an embodiment of the present invention was constructed and tested in accordance with test procedure ASIM E 90-04, Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions. More specifically, the test specimen was a wall assembly constructed from metal studs, resilient (RC) channel, and type X gypsum wallboard. The studs were 3⅝ inch (92 mm) 25-gauge metal MarinoWare Viper studs and were spaced horizontally at 24 inches (607 mm) O.C. A graph plotting sound transmission losses associated with certain test results of an exemplary wall assembly in accordance with the present invention is provided as FIG. 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com