Assembly and method for placing a cement plug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

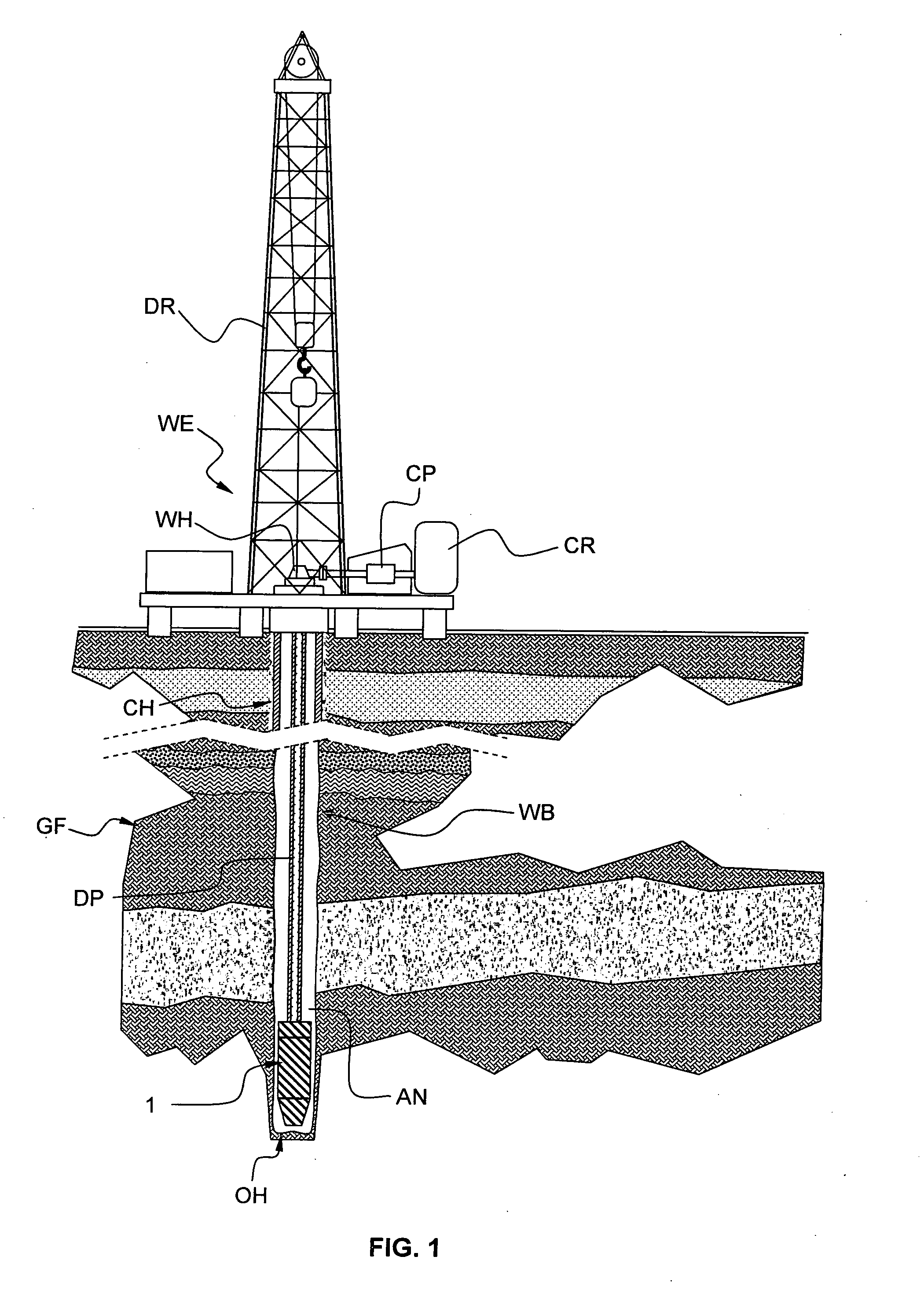

[0030]FIG. 1 schematically shows an onshore hydrocarbon well location and equipments WE above a hydrocarbon geological formation GF after drilling operation has been carried out and after a drill pipe DP has been run. At this stage, the well-bore WB is an open-hole OH generally filled with various fluid mixtures (e.g. the drilling mud or the like). The well-bore WB may also be partially cased CH. The equipment WE comprises a drilling rig DR for running the drill pipe DP in the well-bore, cementing equipment comprising cement silo CR and pumping arrangement CP, and a well head and stuffing box arrangement WH providing a sealing for deploying the drill pipe DP or pumping down the cement into the generally pressurized well-bore WB. Subsequently, cementing operations are generally undertaken to seal the annulus AN (i.e. the space between the well-bore WB and the casing where fluid can flow). A first application is primary cementing which purpose is to achieve hydraulic isolation around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com