Pulse thulium-doped fiber laser device

A fiber laser and laser technology are applied in the field of lasers to achieve the effects of economical cost, high power density of pump light and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

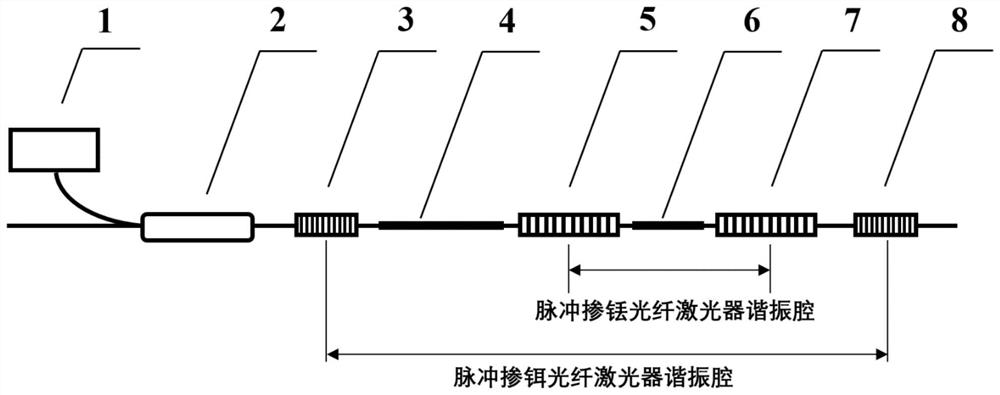

[0030] An embodiment of the present invention provides a pulsed thulium-doped fiber laser, which includes: pump source 1, pump coupling device 2, first 1.5 μm fiber grating 3, erbium-doped active fiber 4, high-reflective thulium-doped fiber laser Fiber Bragg grating 5, Thulium-doped active fiber 6, Thulium-doped fiber laser output fiber Bragg grating 7, second 1.5μm Fiber Bragg grating 8;

[0031] Among them, the pump source 1 is a fiber-coupled multimode semiconductor laser with a wavelength of 976 nm and a fiber core diameter of 100 μm; the pump coupling device 2 is a signal-pump combiner with a pump pigtail core diameter of 100 μm, and the pump source The optical fiber specifications of 1 are matched, and the signal port optical fiber is a single-mode double-clad optical fiber; the first 1.5 μm fiber grating 3 has a high reflectivity for the 1560nm wavelength corresponding to the Tm ion absorption peak in the erbium ion emission spectrum, and the reflectivity is greater than...

Embodiment 2

[0036] In the above-mentioned embodiment 1, the erbium-doped active fiber can be a single erbium-doped fiber, or an erbium-ytterbium co-doped fiber, as long as the gain at the 1.5 μm absorption band corresponding to the thulium-doped active fiber 6 can be provided, the present invention The embodiment does not limit this.

[0037] The pumping source 1 can be a multimode semiconductor laser, or a single transverse mode semiconductor laser or other types of lasers, and the pumping wavelength can be 976nm or 915nm, as long as it corresponds to the pumping of the erbium-doped active fiber 4 The Pu absorption band is sufficient, which is not limited in this embodiment of the present invention.

[0038]Correspondingly, if the pump source 1 is a single transverse mode pump source, the corresponding pump coupling device 2 is a wavelength division multiplexer (WDM) or other type of single-mode coupling device, which is not limited in the embodiment of the present invention .

[0039]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com