Welding Power Supply External Protective Support Structure

a technology of protective support and welding power supply, which is applied in the field of welding systems, can solve the problems of damage to welding power supply, inconvenient and hazardous welding environment, and difficulty in transporting or repositioning welding power supplies, which may weigh over 80 pounds,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

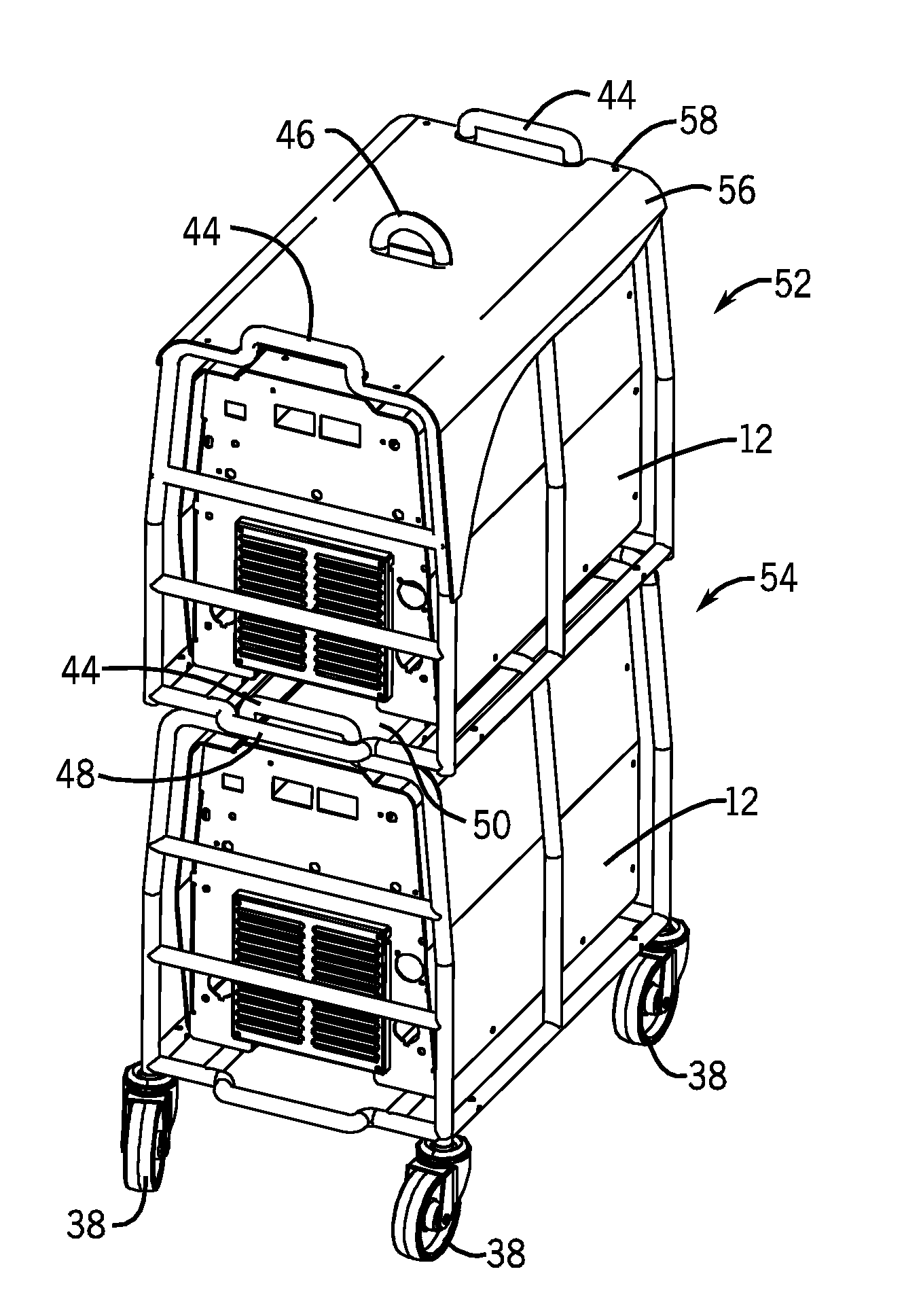

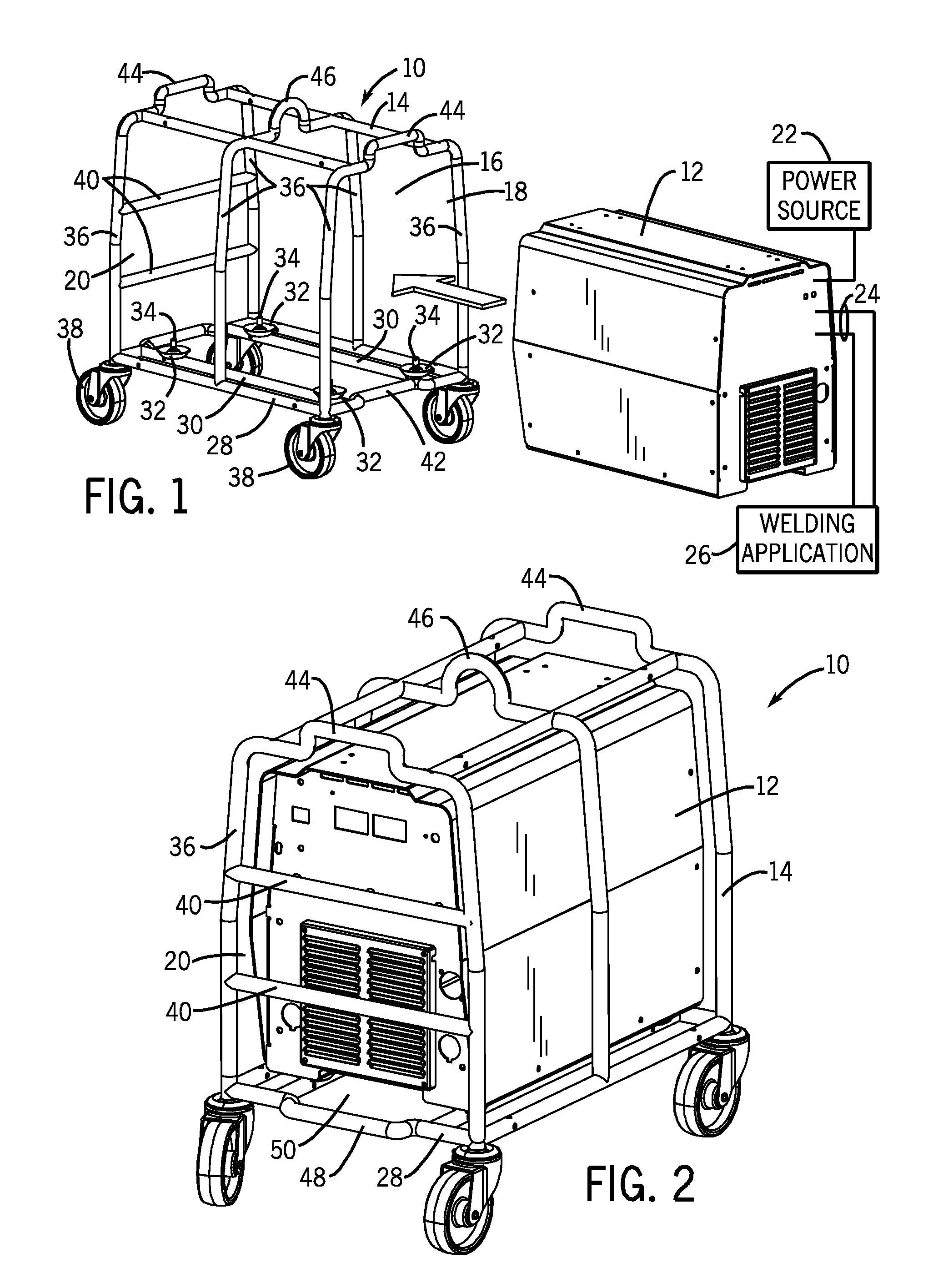

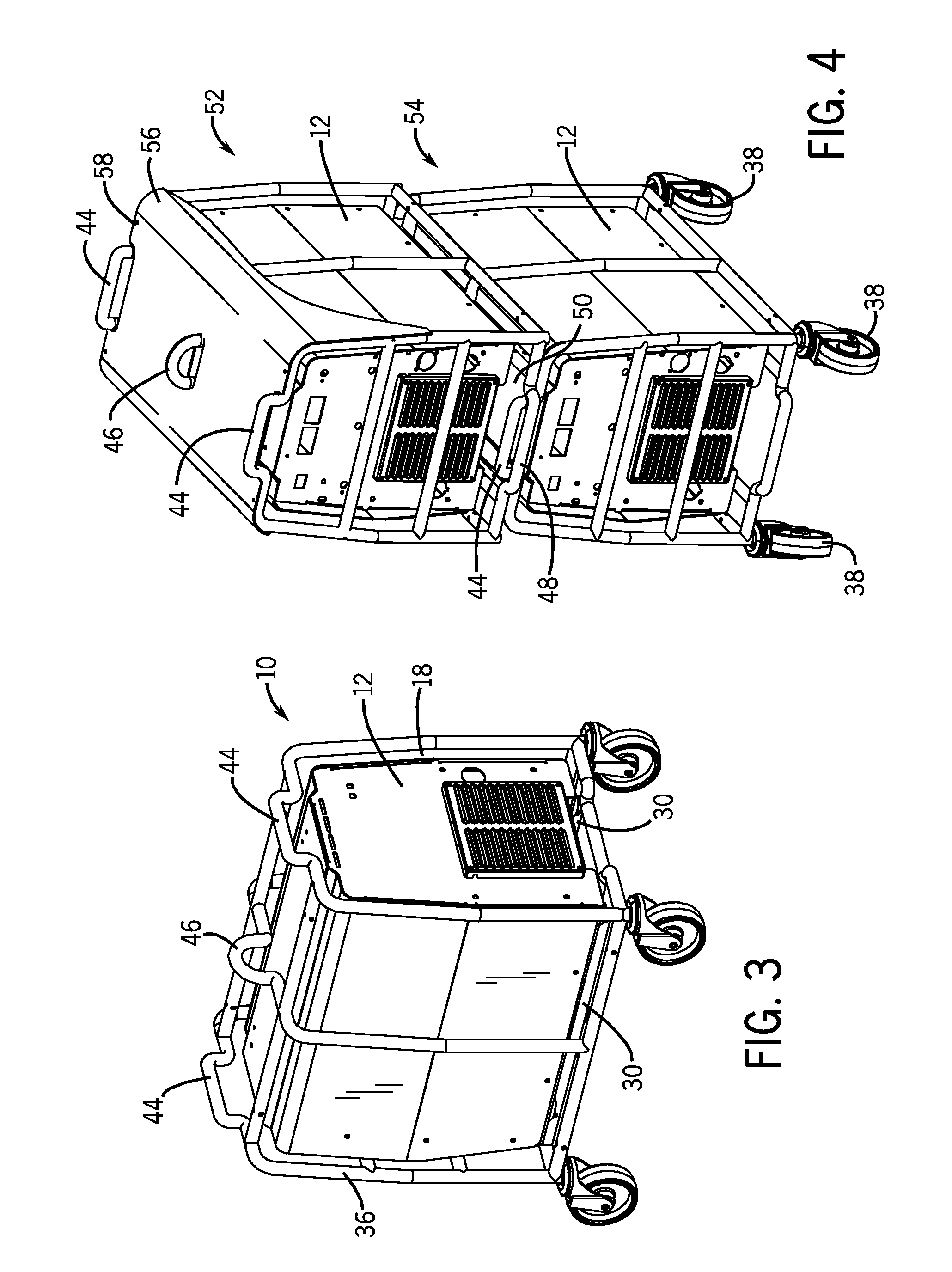

[0010]As discussed further below, embodiments of the presently disclosed external support structure include a cage-like assembly configured to receive a welding power supply. The cage-like assembly includes a plurality of tubular members that at least partially surround the base, top and lateral sides of the welding power supply. The cage-like assembly may further include a number of fasteners for use in securing the welding power supply within the cage-like assembly. In order to facilitate the stacking of two or more self-similar external support structures, the cage-like assembly includes upper and lower support members configured to permit stacking. In addition, the cage-like assembly may include handles of a first configuration and handles of a second configuration such that the handles of a first configuration interlock with the handles of a second configuration when self-similar external support structures are stacked. The cage-like assembly may also include casters to facilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com