Force multiplying retaining straps

a technology of retaining straps and force, which is applied in the direction of fastenings, press-button fasteners, transportation items, etc., can solve the problems of limiting the usefulness of restraints in cramped surroundings associated with articulated lifting assemblies, affecting the effect of restraining or releasing, and cluttered space occupied by the components of articulated lifting mechanisms, so as to achieve the effect of effective restraining or releasing and saving fabrication costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

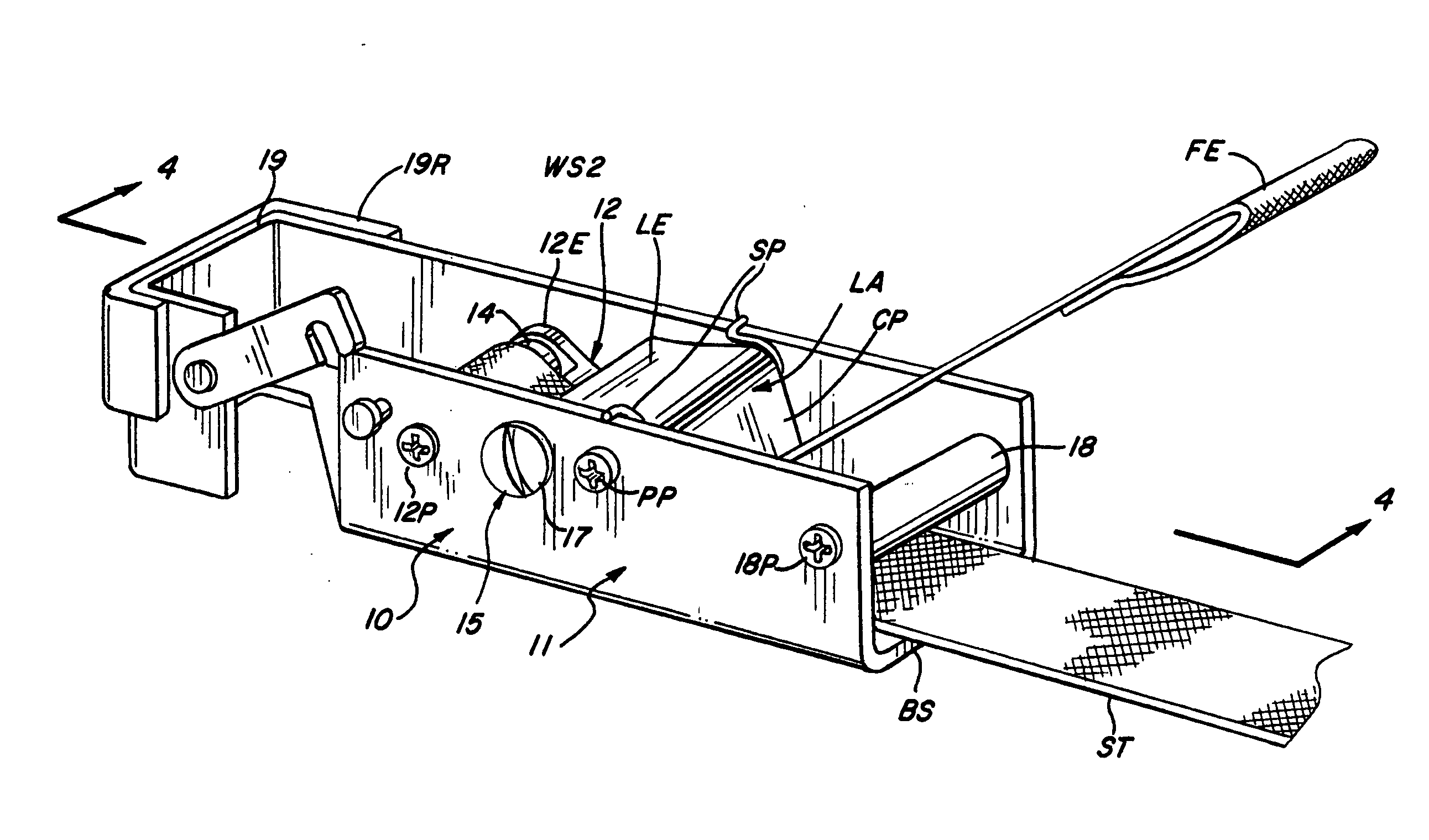

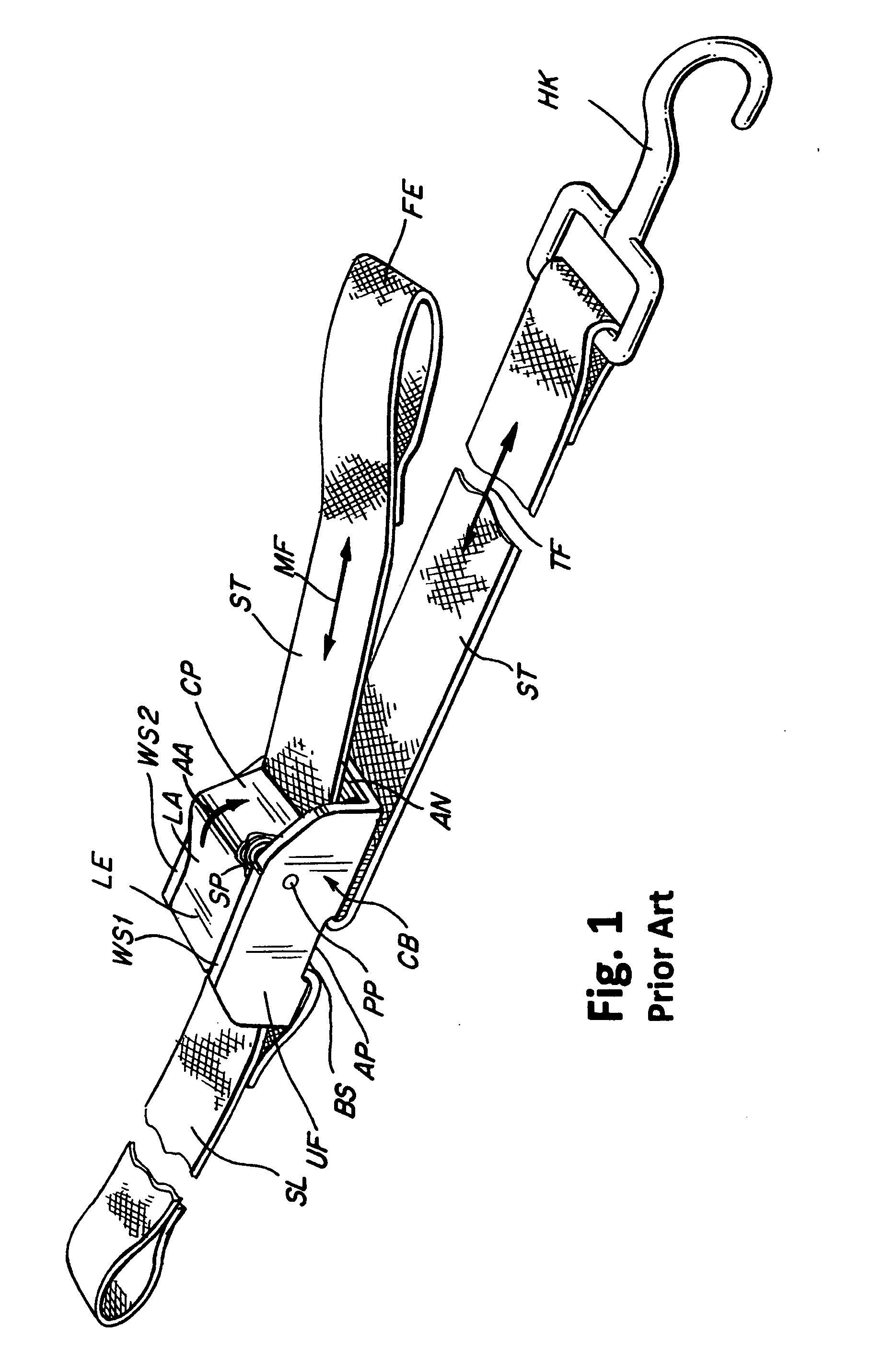

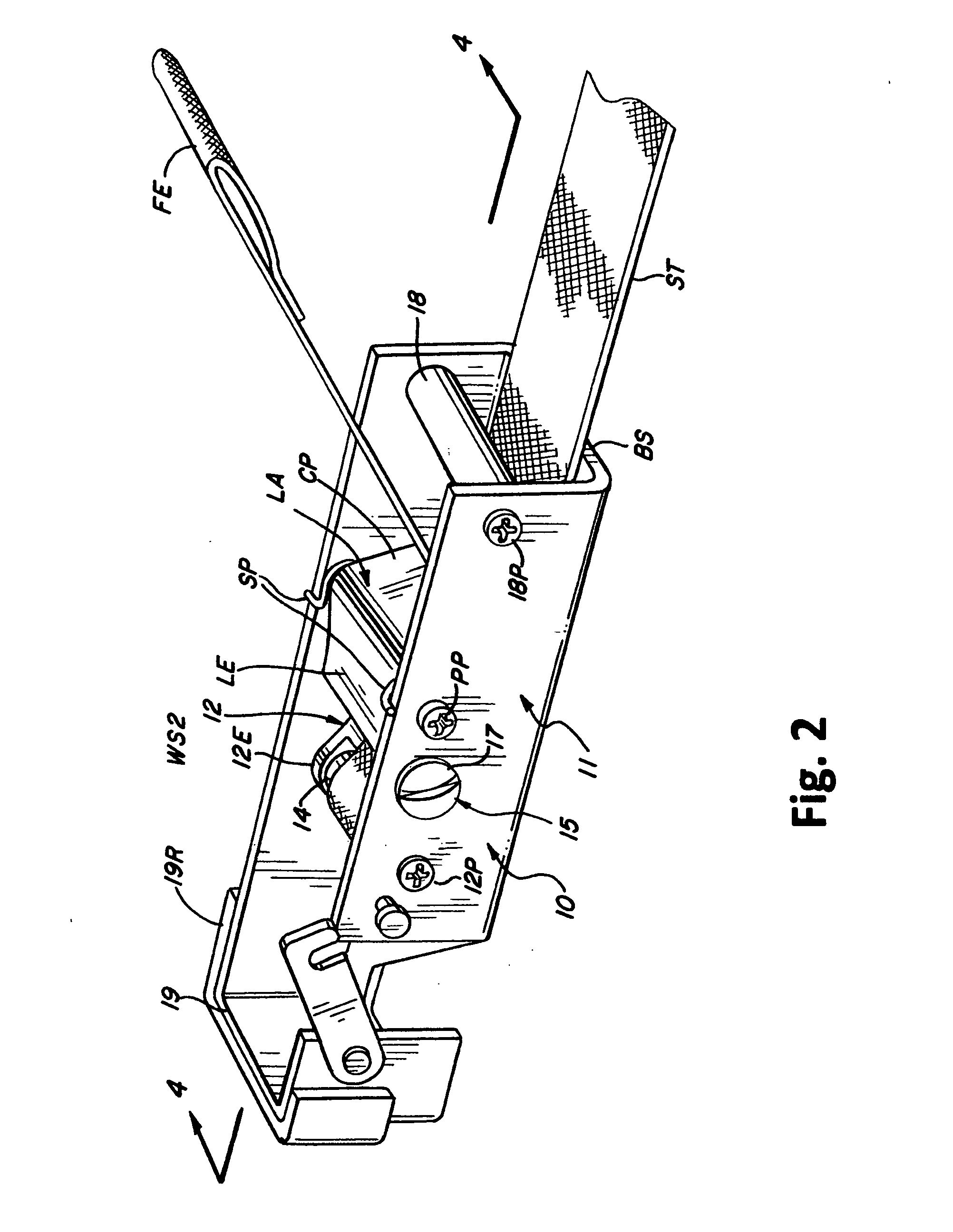

[0028]As shown in FIG. 1 a conventional cam buckle assembly generally designated CB comprises a single piece unitary frame UF of a generally C-shaped section defined by a bottom surface BS spanning between two lateral walls WS1 and WS2. A transverse pivot pin PP extends between the walls WS1 and WS2 proximate the one ends thereof to support an L-shaped lever assembly LA at the junction of a lever LE and a generally orthogonal cam piece CP.

[0029]A helical bias spring SP on pin PP is compressed between wall WS1 and the lever LE to urge the free end of the cam piece CP in the direction of arrow AA towards an anvil piece AN supported on the bottom surface BS, capturing a load carrying strap ST therebetween as it is passed through an aperture AP in the bottom surface BS against the tension force TF carried by the strap to an end hook HK corresponding to the manually applied tensioning force at the strap's free end FE. A strap loop SL around the other portion of the bottom surface BS bord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com