Ice-making machine

a technology of ice-making machines and ice-making pieces, which is applied in the field of ice-making machines, can solve the problems of affecting the production of “clean” ice, affecting the quality of ice, so as to achieve the effect of keeping the concentration of water salt in acceptable levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

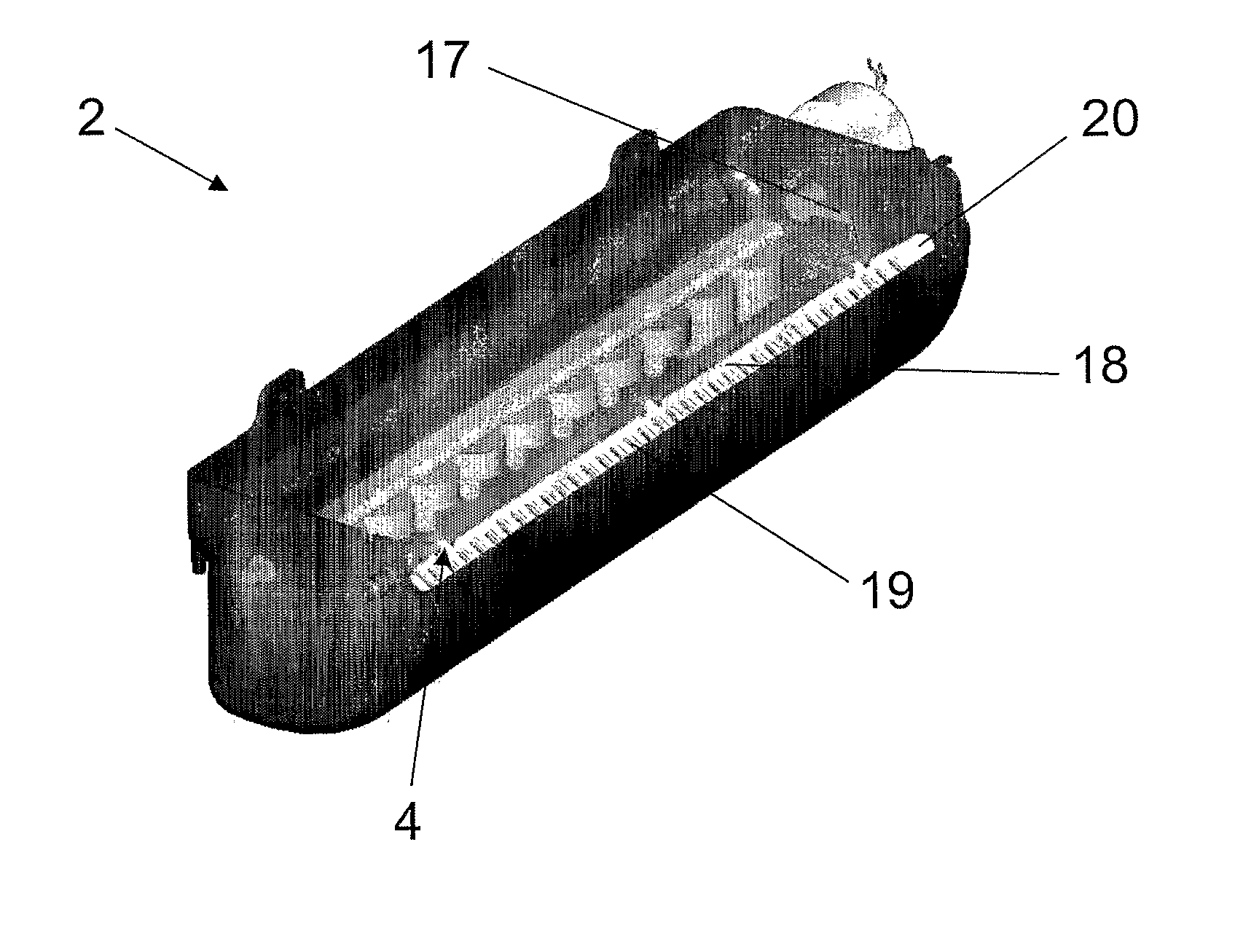

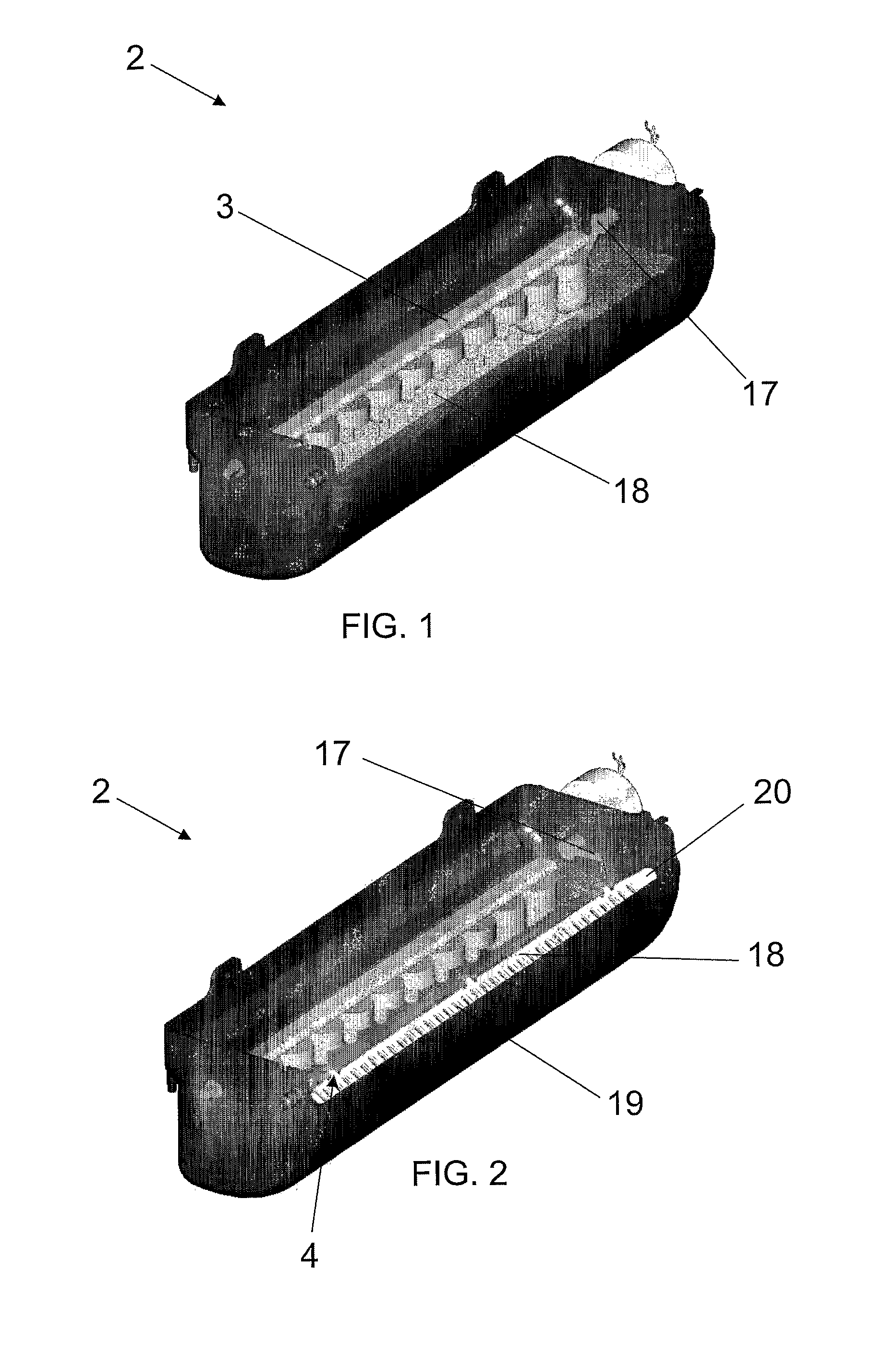

Image

Examples

Embodiment Construction

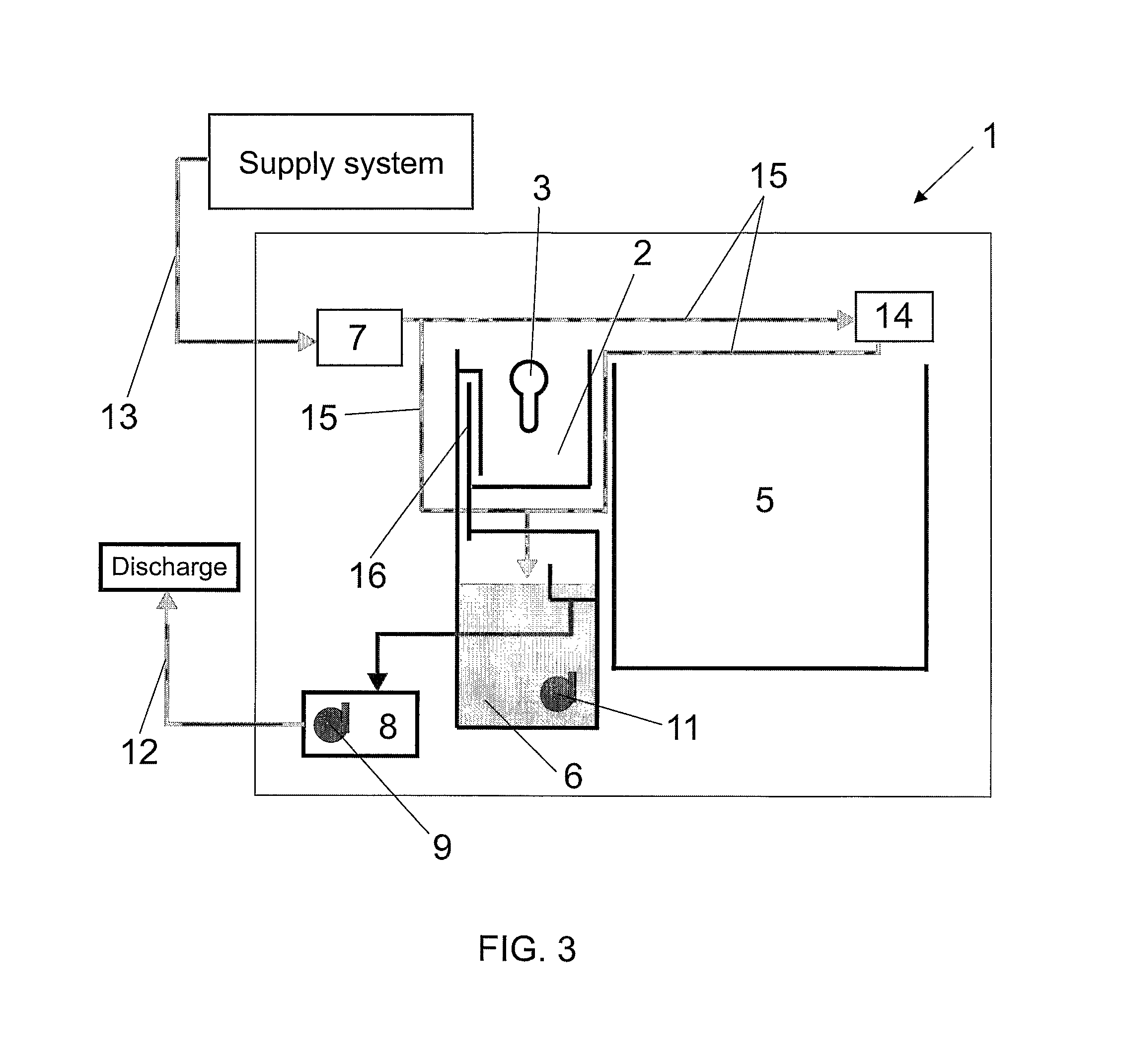

[0023]The ice-making machine 1 under the present invention ideally comprises an auxiliary tank 6, an ice formation reservoir 2 and at least one region 5 of ice pieces produced in the reservoir 2. Other components can be provided with this machine, above-mentioned components being the main components for realization of the present invention.

[0024]Referring to FIG. 3, machine 1 comprises, in addition to above-mentioned elements, an intake piping 13 associated with a water supply system, a supply valve 7 and optionally a filter 14. Thus, according to this construction, the ice formation cycle initiates with the water supply to auxiliary tank 6, where in first the water of a supply system runs the intake piping 13 up to the supply valve 7, from which it will be stored in the auxiliary tank 6.

[0025]The supply system in question consists of a public water supply or other variations, such as tanks and other reservoirs having as objective to supply water to machine 1 of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com