Cooling load prediction based optimal control method of ice-storage system

A control method and system optimization technology, applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc., can solve the problem of increasing investment costs, running out of ice in the ice storage tank, and unable to meet the peak cooling load, etc. problems, to achieve the effect of improving operating efficiency, reducing operating costs, and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

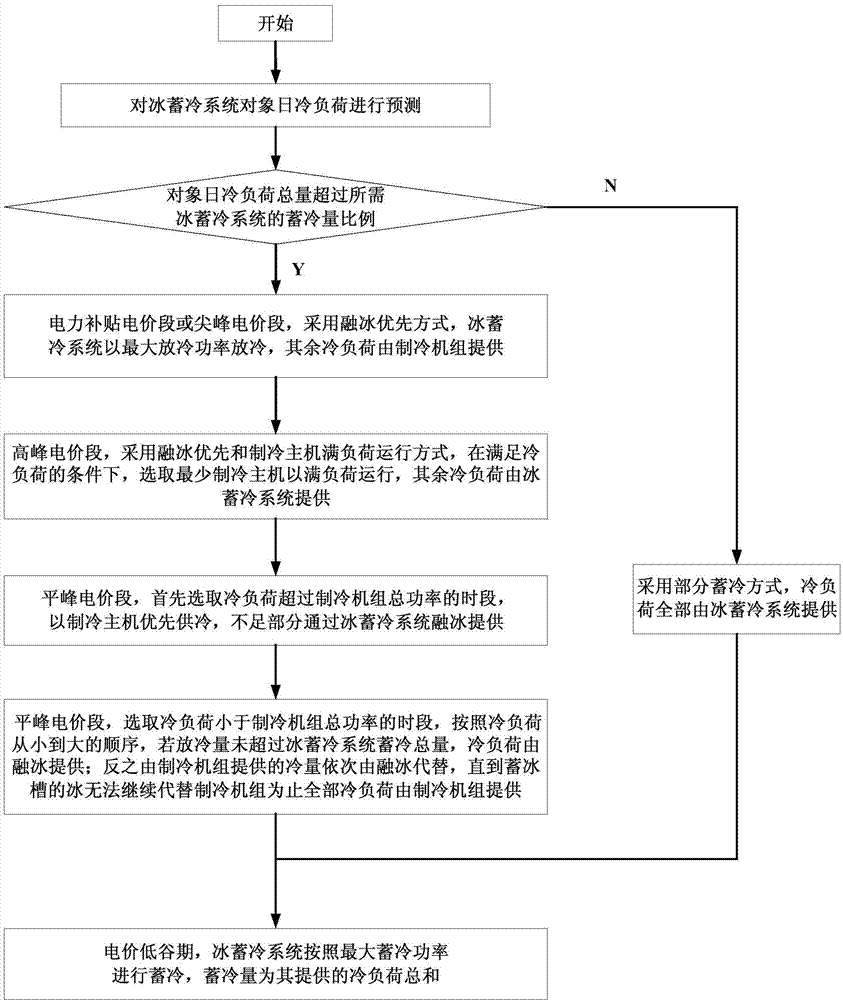

Method used

Image

Examples

Embodiment 1

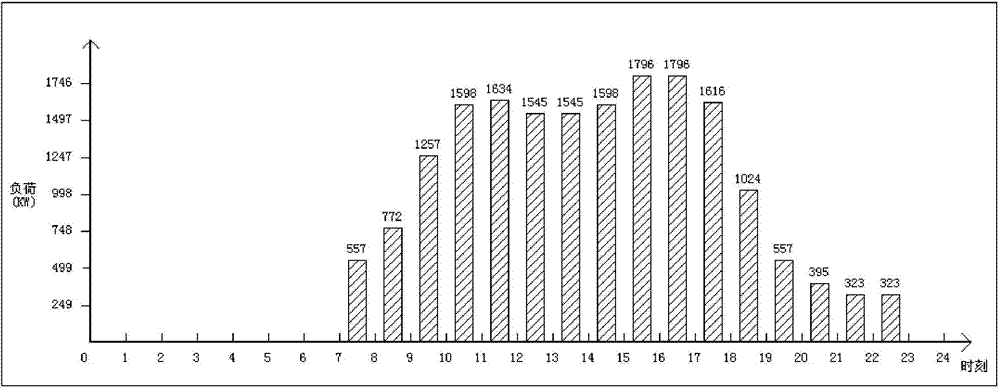

[0045] figure 2 Shown is a 100% design day hourly cooling load distribution diagram of a building. The cold storage capacity of the ice storage system is designed according to 35% of the total daily cooling load of the building design. The total cold storage capacity of the ice storage tank is 6960RTH. The cooling capacity of the two refrigerating units is 516RT under the air-conditioning condition, and 435RT under the ice storage condition. The electricity price of the building is divided into four periods: peak electricity price period (11:00~12:00, 15:00~16:00), peak electricity price period (9:00~11:00, 14:00~15:00, 17:00~21:00), flat peak electricity price section (7:00~9:00, 12:00~14:00, 16:00~17:00, 21:00~23:00), low valley electricity price section ( 23:00~7:00).

[0046] The control strategy of the ice storage system is realized based on the hourly cooling load distribution of the forecasted day. According to the hourly cooling load and the corresponding temperatur...

Embodiment 2

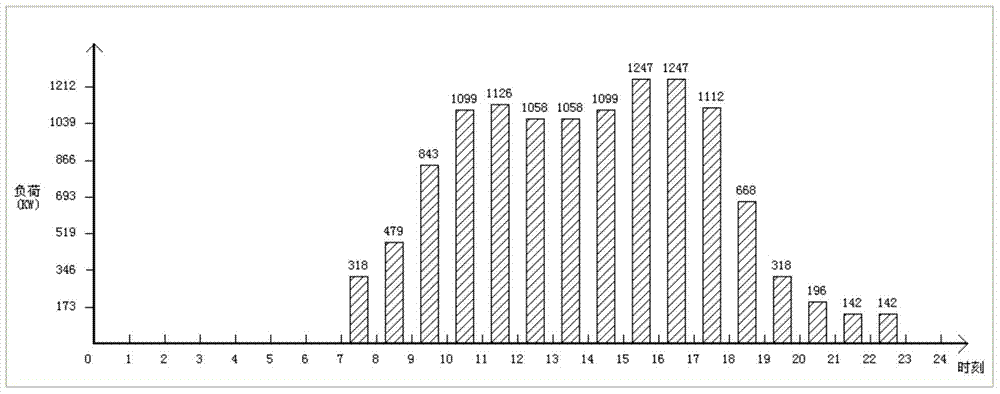

[0054] The cold storage capacity of the ice storage system is generally designed according to more than 30% of the total daily hourly cooling load of the 100% building design. If the predicted daily hourly cooling load is less than the total cold storage capacity of the ice storage system, all cooling loads Cooling system is provided for melting ice. Under the condition that the forecast day is 25% of the design day hourly cooling load operation condition, the control strategy is as follows Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com