CFD software based method for optimizing temperature distribution of power battery pack

A power battery pack, temperature distribution technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of slow same temperature process, damage battery cell life, damage battery cells, etc., to improve performance , Reduce the development cycle and reduce the cost of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

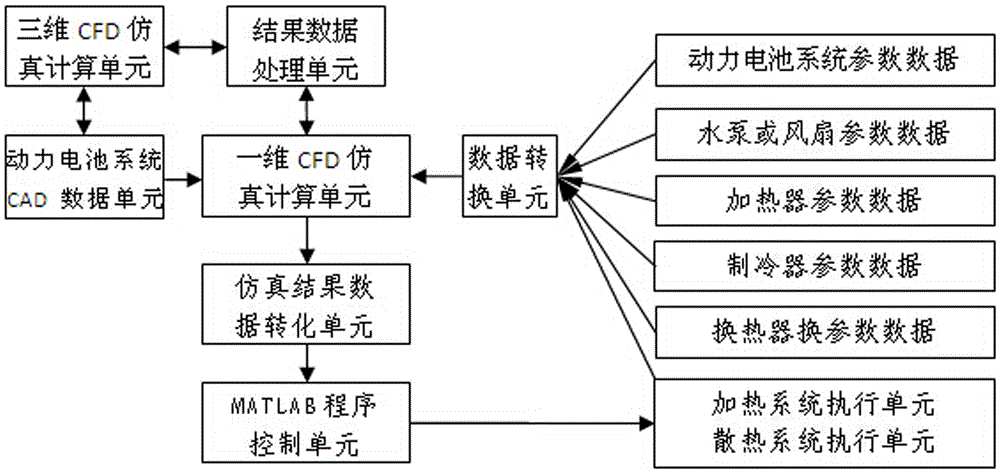

[0020] Depend on figure 1 As shown, this example includes a parameter data unit and a power battery system CAD data unit; the parameter data unit is connected to the input end of the one-dimensional CFD simulation calculation unit through a data conversion unit; the power battery system CAD data unit is connected to the one-dimensional CFD simulation calculation unit respectively The calculation unit is connected with the three-dimensional CFD simulation calculation unit, and the three-dimensional CFD simulation calculation unit is connected with the one-dimensional CFD simulation calculation unit through the result data processing unit; the output end of the one-dimensional CFD simulation calculation unit is sequentially passed through the result data processing unit and the MATLAB program The control unit is connected with the execution unit of the heating system and the heat dissipation system; the output end of the execution unit of the heating system and the heat dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com