Discharging device for liquids

a liquid storage device and liquid technology, applied in liquid dispensing, medical atomisers, inhalators, etc., can solve the problems of unfavorable use of self-supporting rigid films that are converted into three-dimensional objects through thermoforming/deep drawing processes, and the comparatively high cost factor, so as to achieve low storage space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

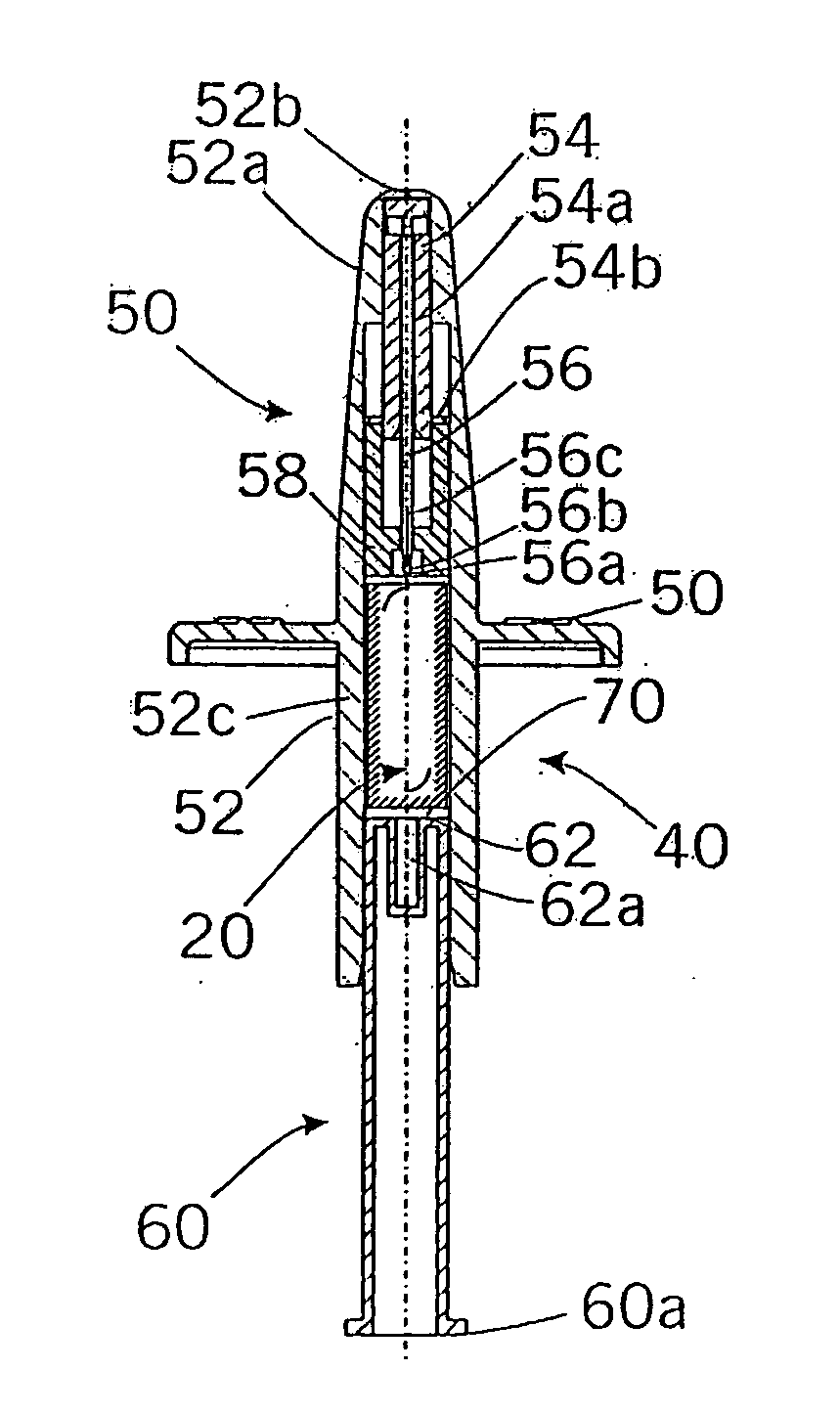

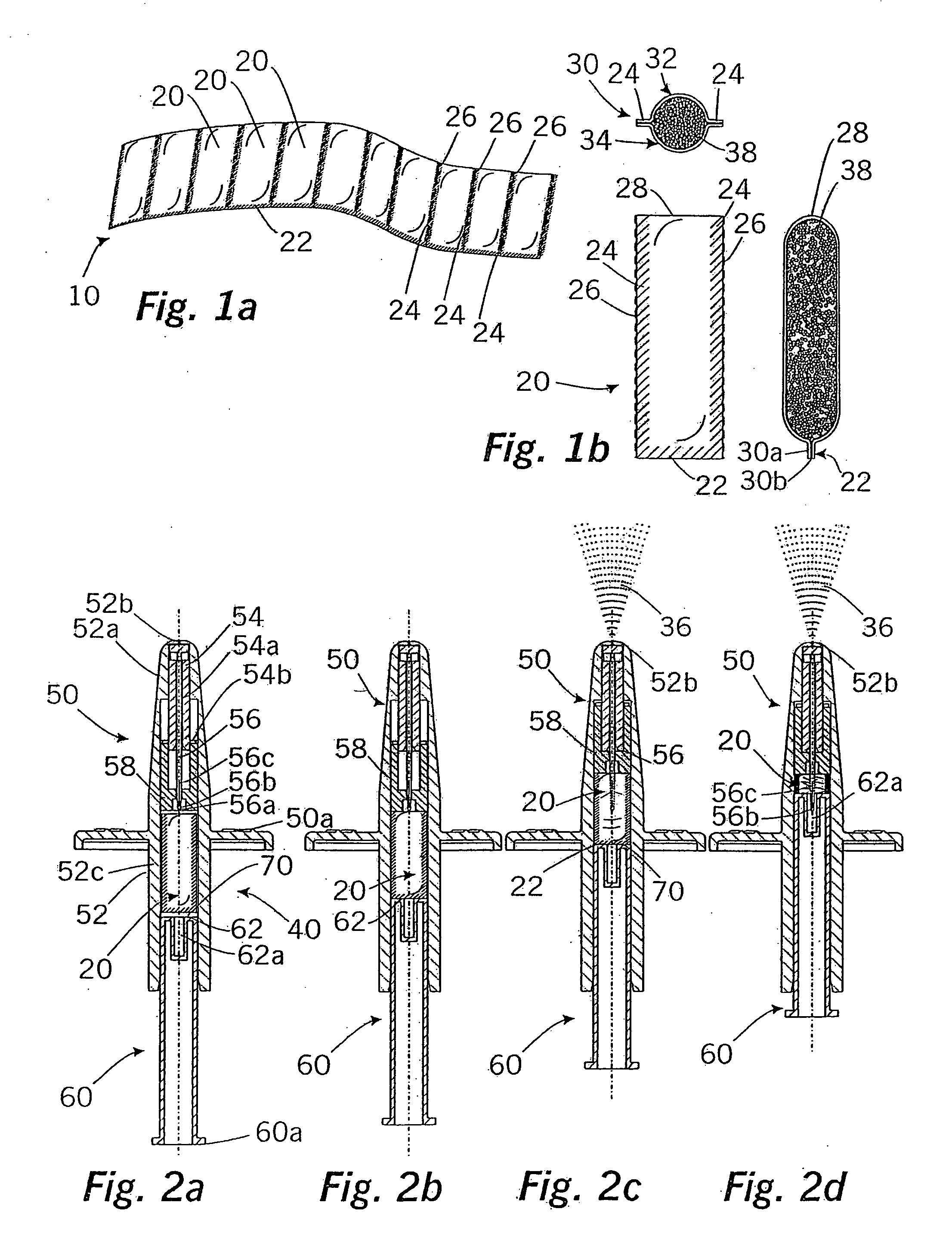

[0043]FIGS. 2a to 2d show a discharging device for the discharge of liquid 38 from a liquid-containing bag 20. Apart from the liquid-containing bag 20, this discharging device comprises an actuator 40. This actuator 40 in turn comprises a first subordinate unit 50 and a second subordinate unit 60 that is manually displaceable relatively to the first subordinate unit 50 in accordance with the designated use of the discharging device.

[0044]The first subordinate unit 50 consists of a sleeve-like component 52, at the top end of which a nasal tube 52a is provided. The end of the nasal tube 52a is in the form of a discharge orifice 52b. At its opposite end, the component 52 comprises a cylindrically hollow portion 52c for the accommodation of the second subordinate unit 60. Inside the sleeve-shaped component 52, the first subordinate unit 50 comprises an insert 54, which, for production reasons, is a separate component but is permanently connected to the component 52. In this insert there...

second embodiment

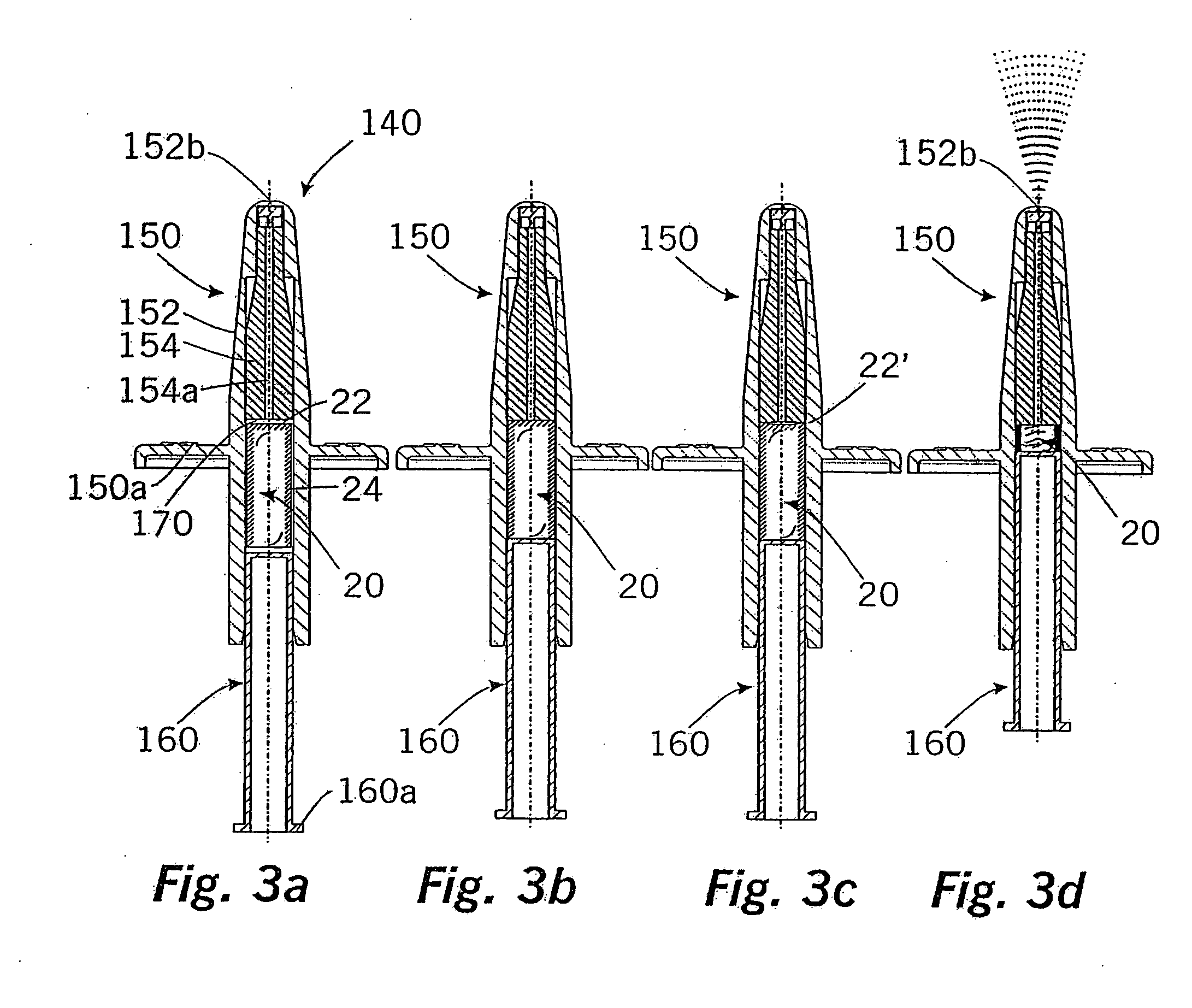

[0053]In the second embodiment illustrated, the liquid-containing bag 20 is not opened by opening means such as a hollow needle 56 as described above, but exclusively by the internal pressure therein. However, provision can be made for the liquid-containing bag 20 to have deliberately provided weak portions in order to achieve a reproducible opening behavior. In this embodiment, the side of the liquid-containing bag 20 that is oriented in the direction of the liquid passageway 154a is provided with a weak longitudinal seam 22, the breakdown of which may be expected to occur prior to the breakdown of the transverse seams 24.

[0054]Starting from the state shown in FIG. 3a, a pressure increase will again be achieved in the liquid-containing bag 20 of the second embodiment by the application of force to the finger supports 150a, 160a. When the actuating force is sufficiently high (approximately 20 Newton) and the internal pressure in the liquid-containing bag has consequently reached a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com