Rocker arm landing gear

A landing gear and articulation technology, applied in the field of rocker landing gear, can solve the problems of huge retractable space, serious weight, and lack of practicability, and achieve the effect of low retractable space requirements and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

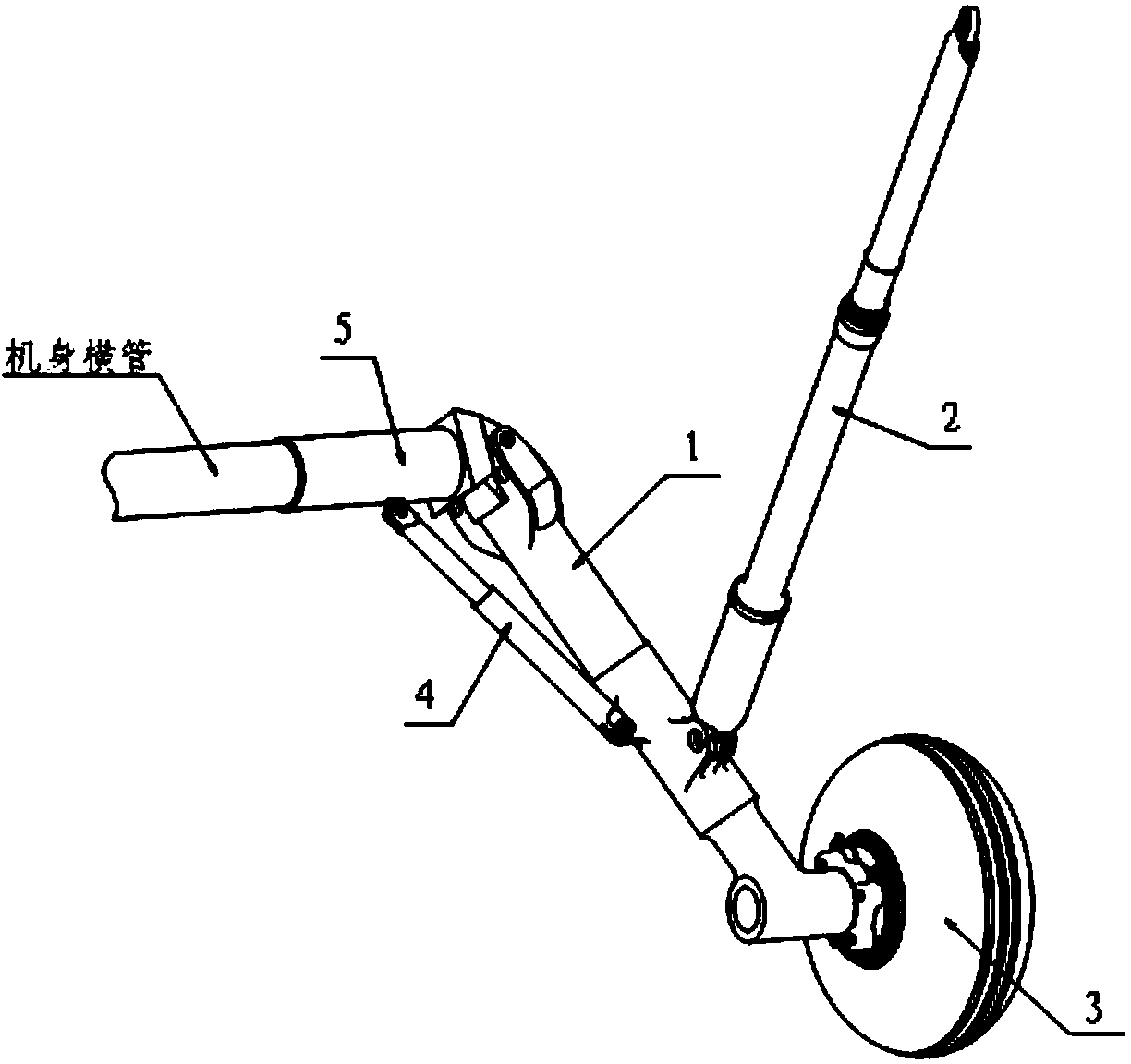

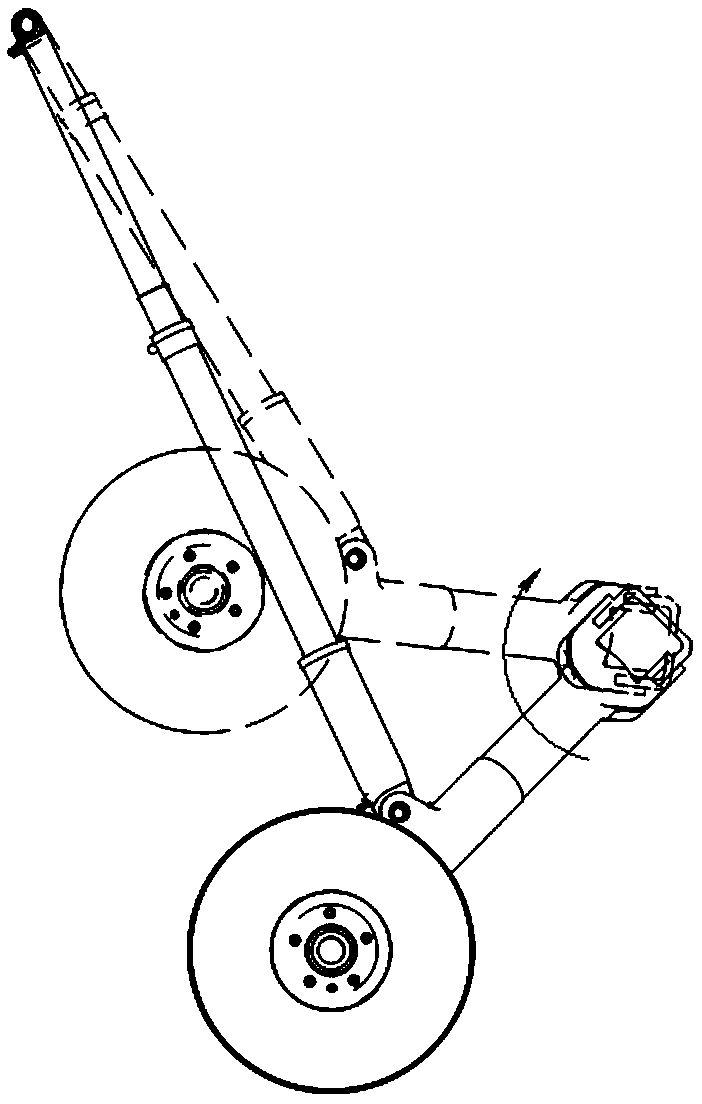

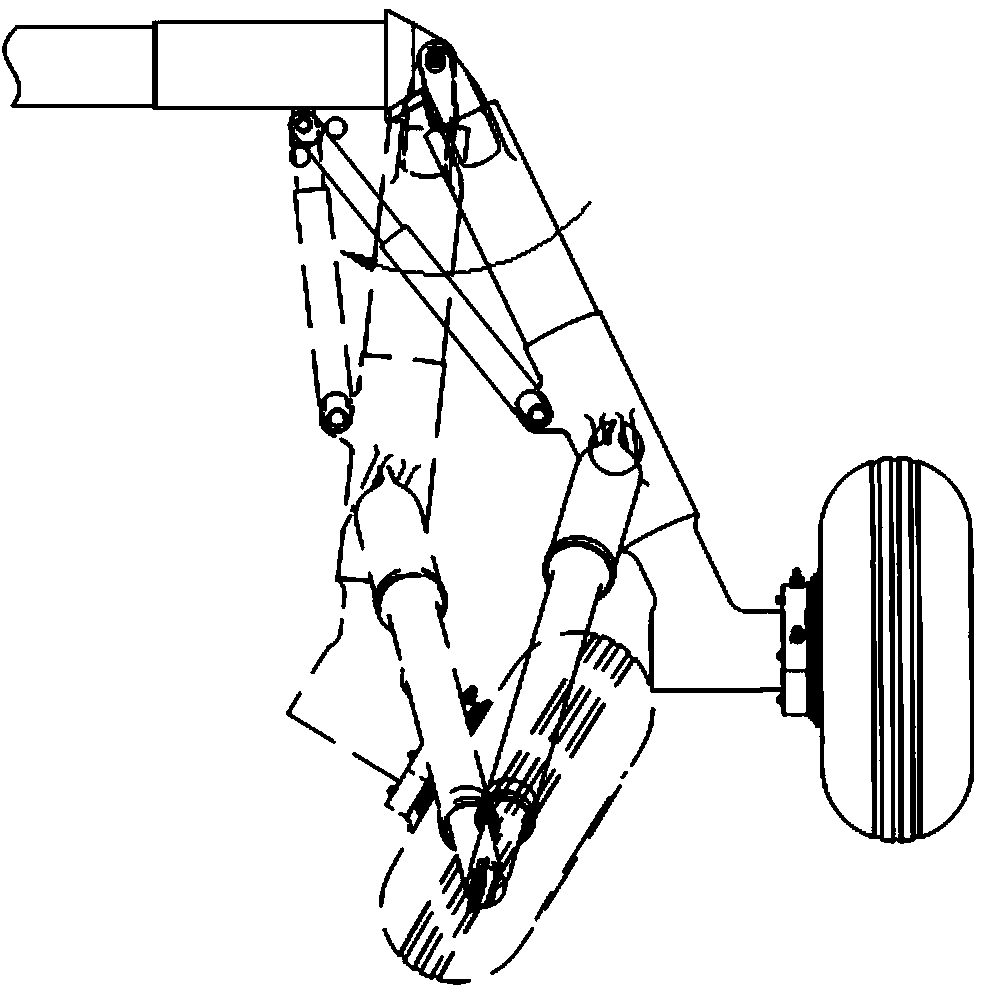

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings. A rocker landing gear, comprising a rocker 1, a buffer 2, a wheel 3, a retractable mechanism 4, a round pipe joint 5, the round pipe joint 5 is hinged with the fuselage; the rocker 1 is hinged with the round pipe joint 5, and can be wound around The round pipe joint 5 rotates; one end of the retractable mechanism 4 is hinged with the round pipe joint 5, and the other end is hinged with the fuselage; one end of the buffer 2 is hinged with the rocker arm 1, and the other end is hinged with the fuselage.

[0023] During installation, at first machine wheel 3, round pipe joint 5, retractable mechanism 4 are connected with rocking arm 1, then round pipe joint 5 is connected with fuselage by bolt. Then install the buffer, when installing the buffer 2, now connect the upper joint of the buffer to the fuselage by bolts, then swing the buffer and the rocker arm to align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com