Reinforcement Bar Support Device

a technology of reinforcement bar and support device, which is applied in the direction of building reinforcements, building material handling, construction, etc., can solve the problems of high project cost, difficulty in achieving high project cost, and achieve the effect of full tensile strength capability, high project cost, and expensive and time-consuming corrections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

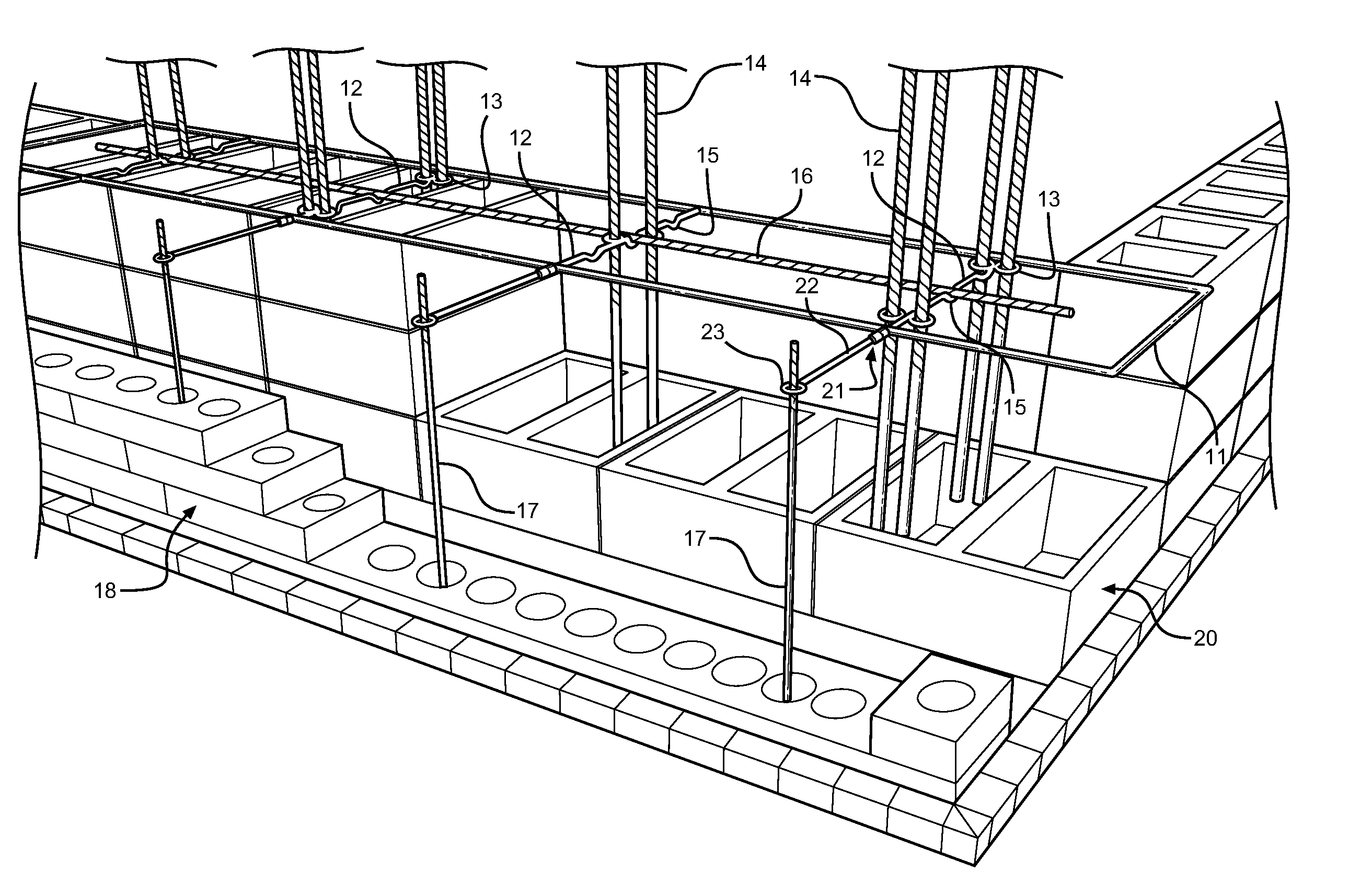

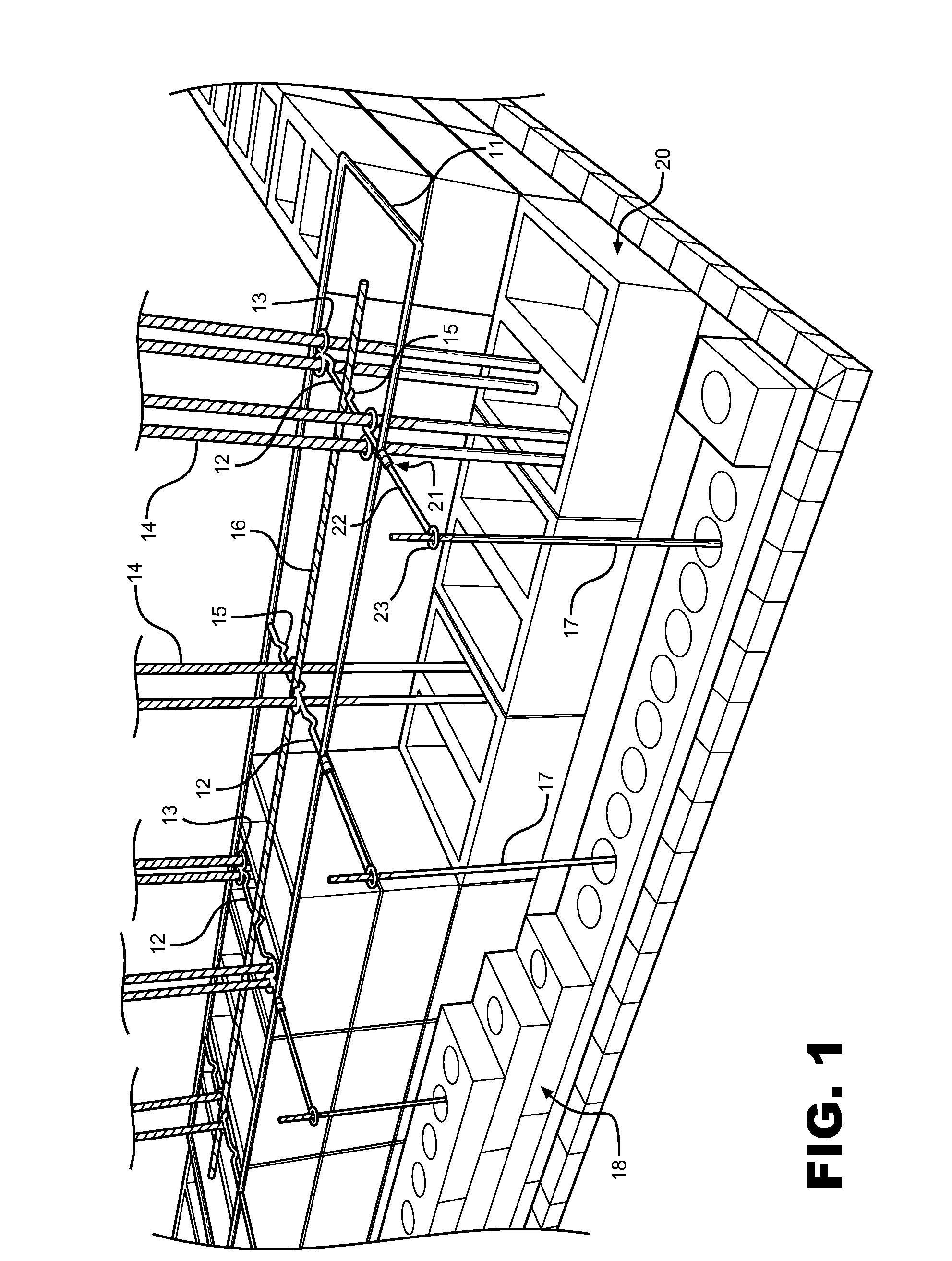

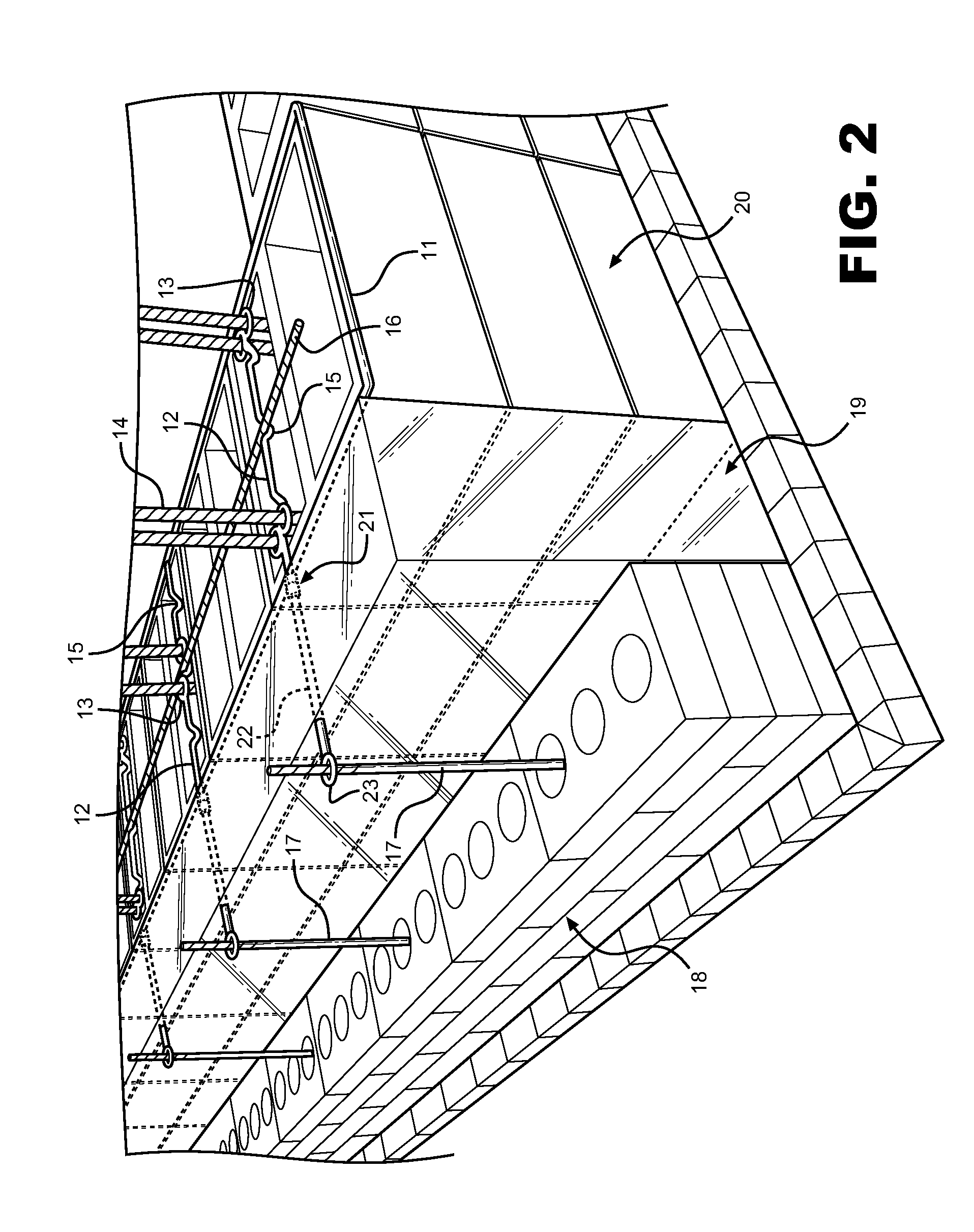

[0023]The present invention provides masons, construction crews, and other individuals with a modular reinforcement bar positioning system for use in concrete masonry unit walls. This device may be comprised of a modular, planar frame that holds a plurality of cross members, creating a design that is similar in appearance to a ladder. The gauge and material of the frame and cross members may be any suitable or desirable to one skilled in the art, include 9-gauge steel wire. Said cross members may be crimped for holding a horizontal rebar at precise locations or bent into circles for securing around a vertical reinforcement bar at a precise location. Each cross member may be spot welded at its ends to the frame. In use, the device may be placed along the length of the block wall in a horizontal mortar joint allowing individuals to securely place vertical and horizontal rebar in the correct positions within the blocks. Multiple modules of the device can be placed at varying levels to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap