Working table having vacuum mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

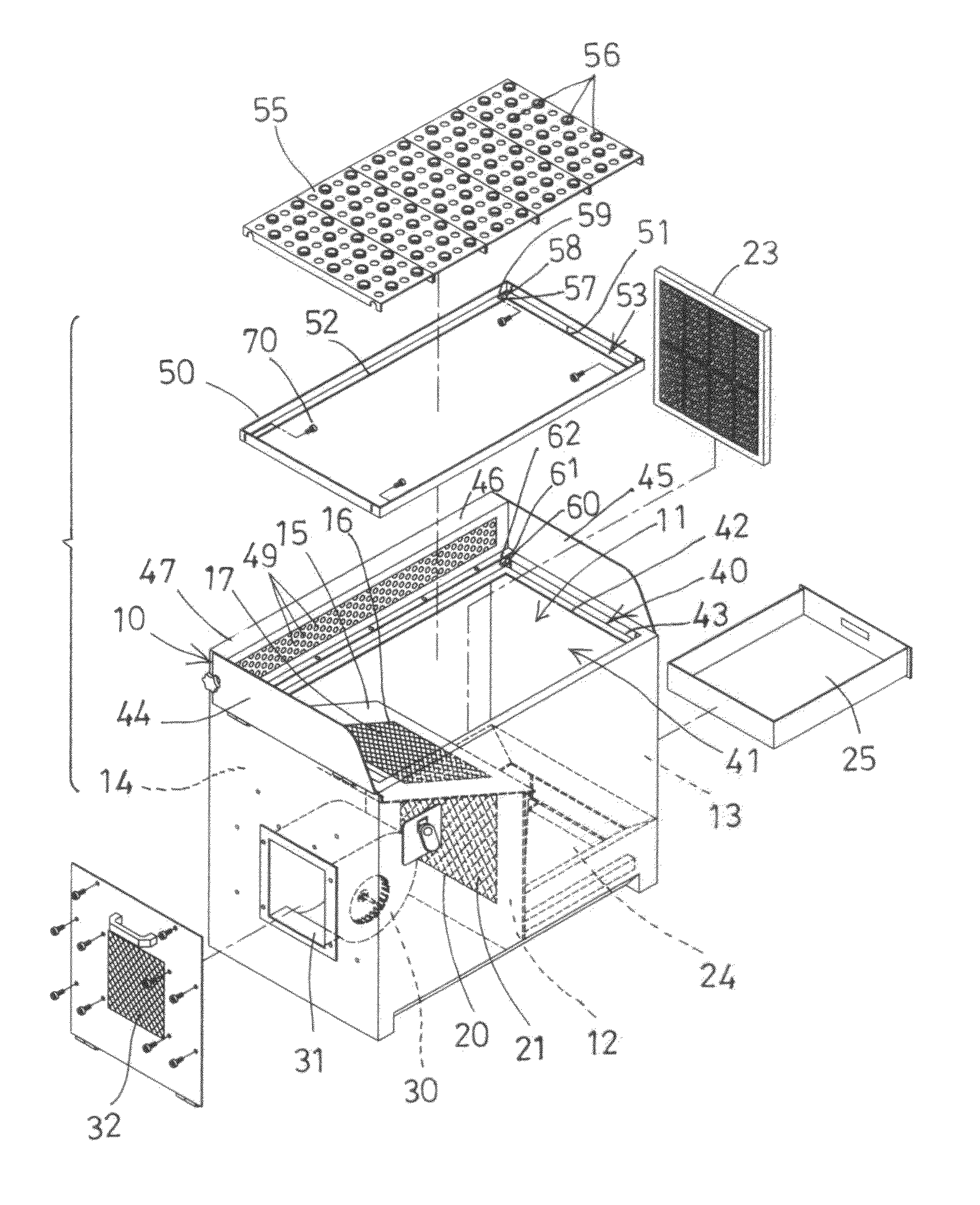

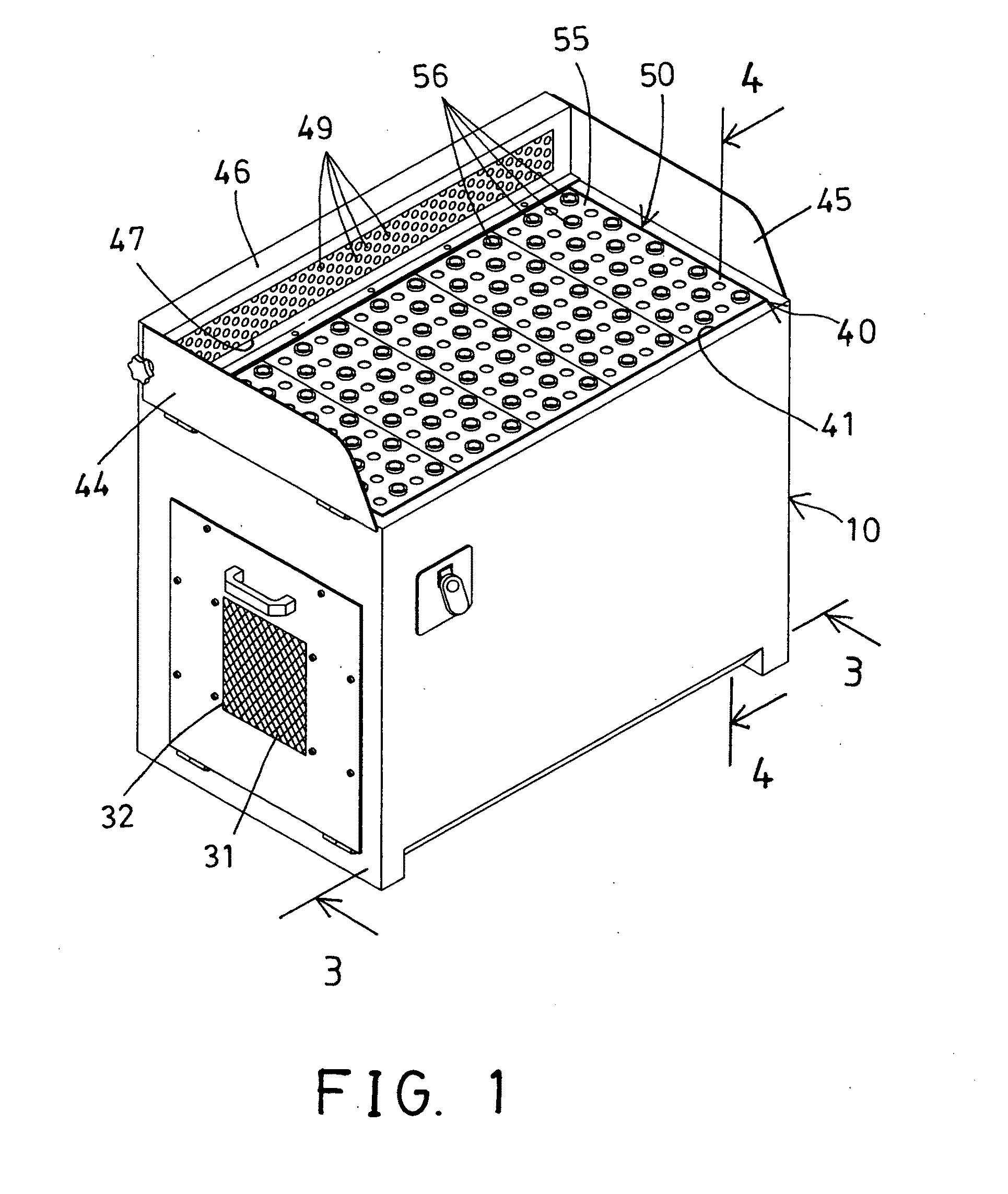

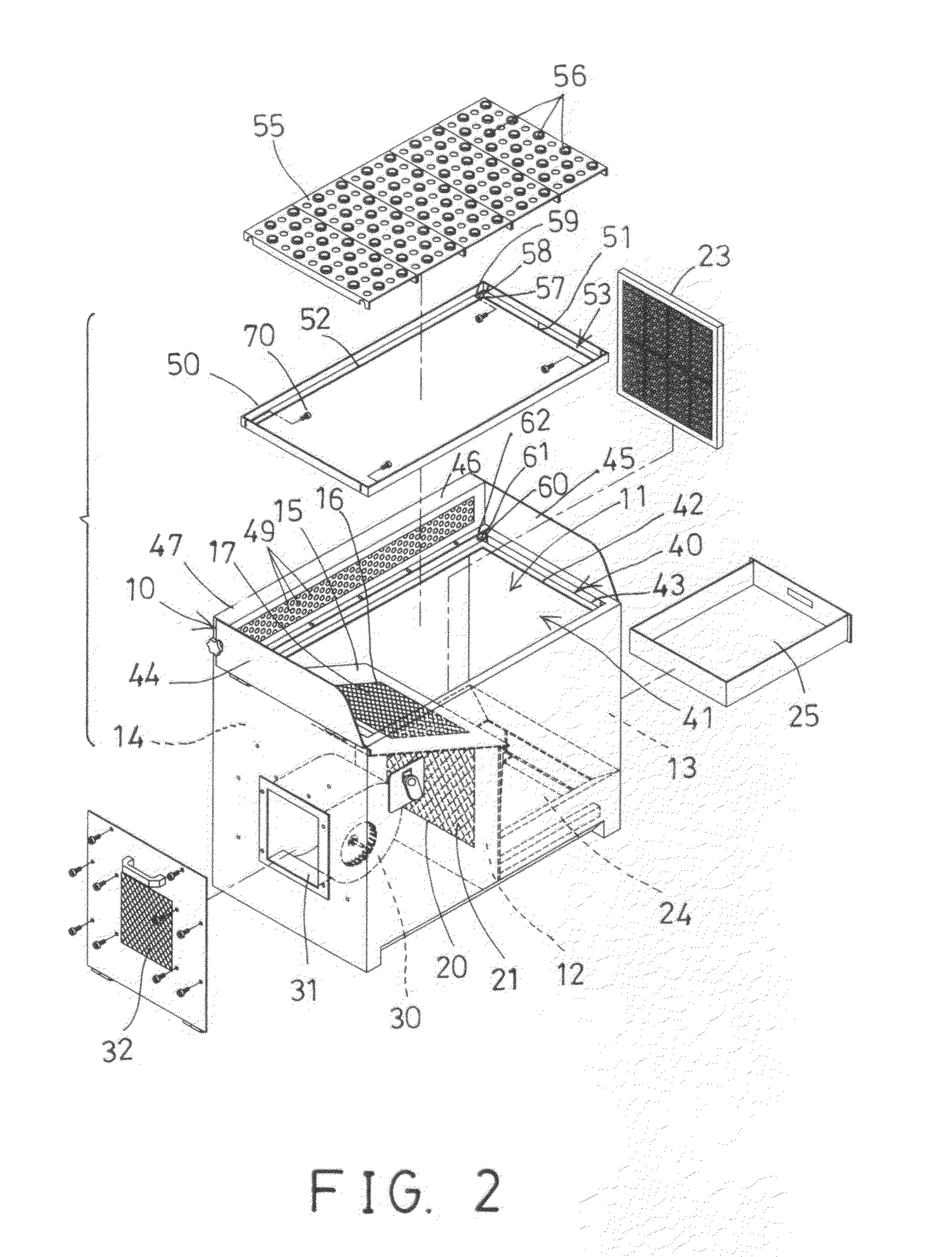

[0026]Referring to the drawings, and initially to FIGS. 1-3, a working table in accordance with the present invention comprises a receptacle or table housing 10 including a chamber 11 formed therein, and including a partition 12 disposed or attached or mounted or secured in the middle portion of the chamber 11 of the housing 10 for separating the chamber 11 of the housing 10 into a dust receiving and collecting compartment 13 and an air drawing and vacuuming compartment 14, and including a dust guide plate 15 disposed or attached or mounted in one side of the housing 10 and located above the air drawing and vacuuming compartment 14, and preferably tilted or inclined relative to the partition 12 and the housing 10 for suitably guiding and directing the dusts or contaminants into the dust receiving and collecting compartment 13 of the housing 10.

[0027]The dust guide plate 15 includes an opening 16 formed therein for attaching or mounting or securing a fine net member 17, and includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com