Dual-density EVA footwear mid-sole and method for making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

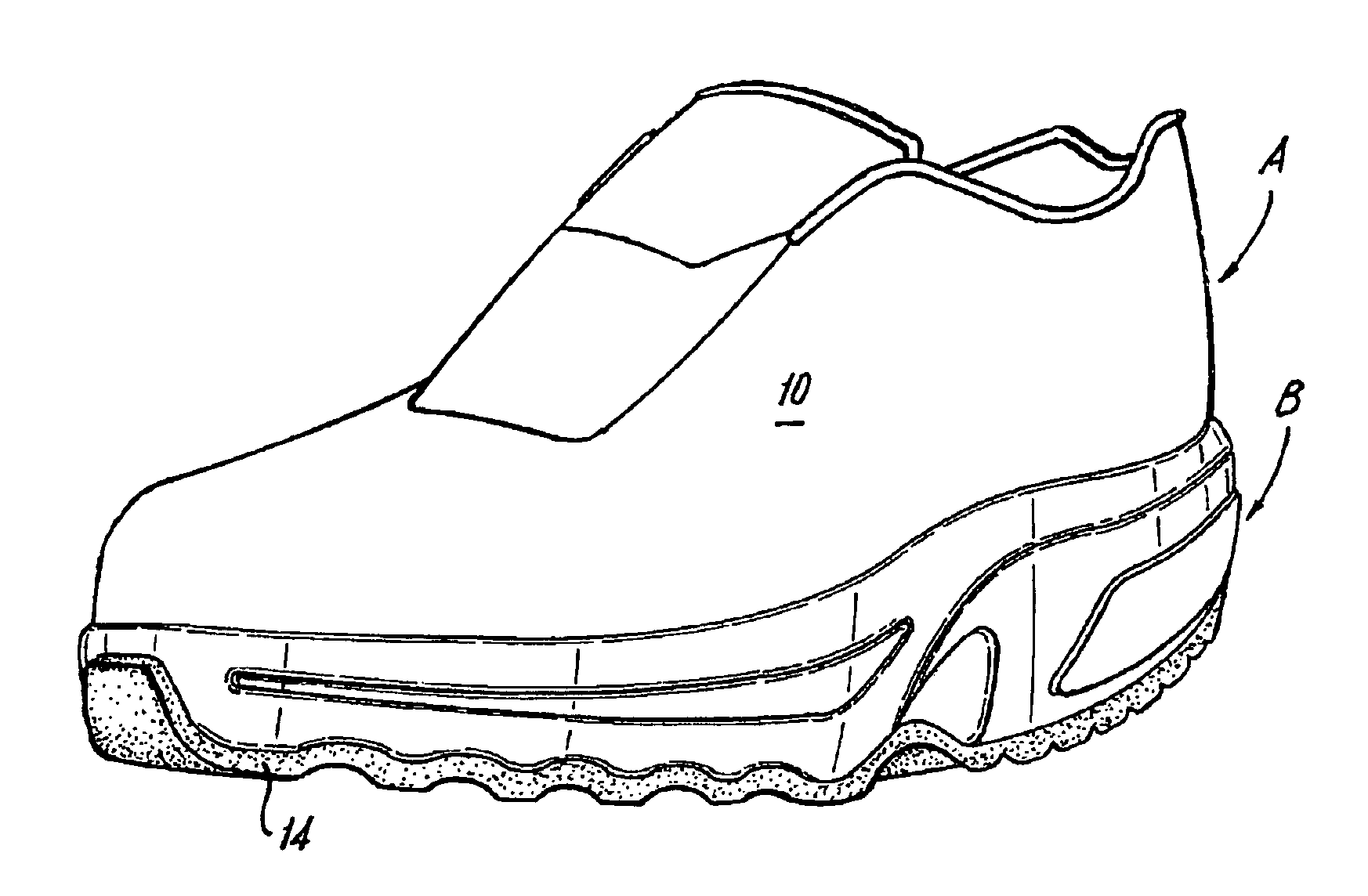

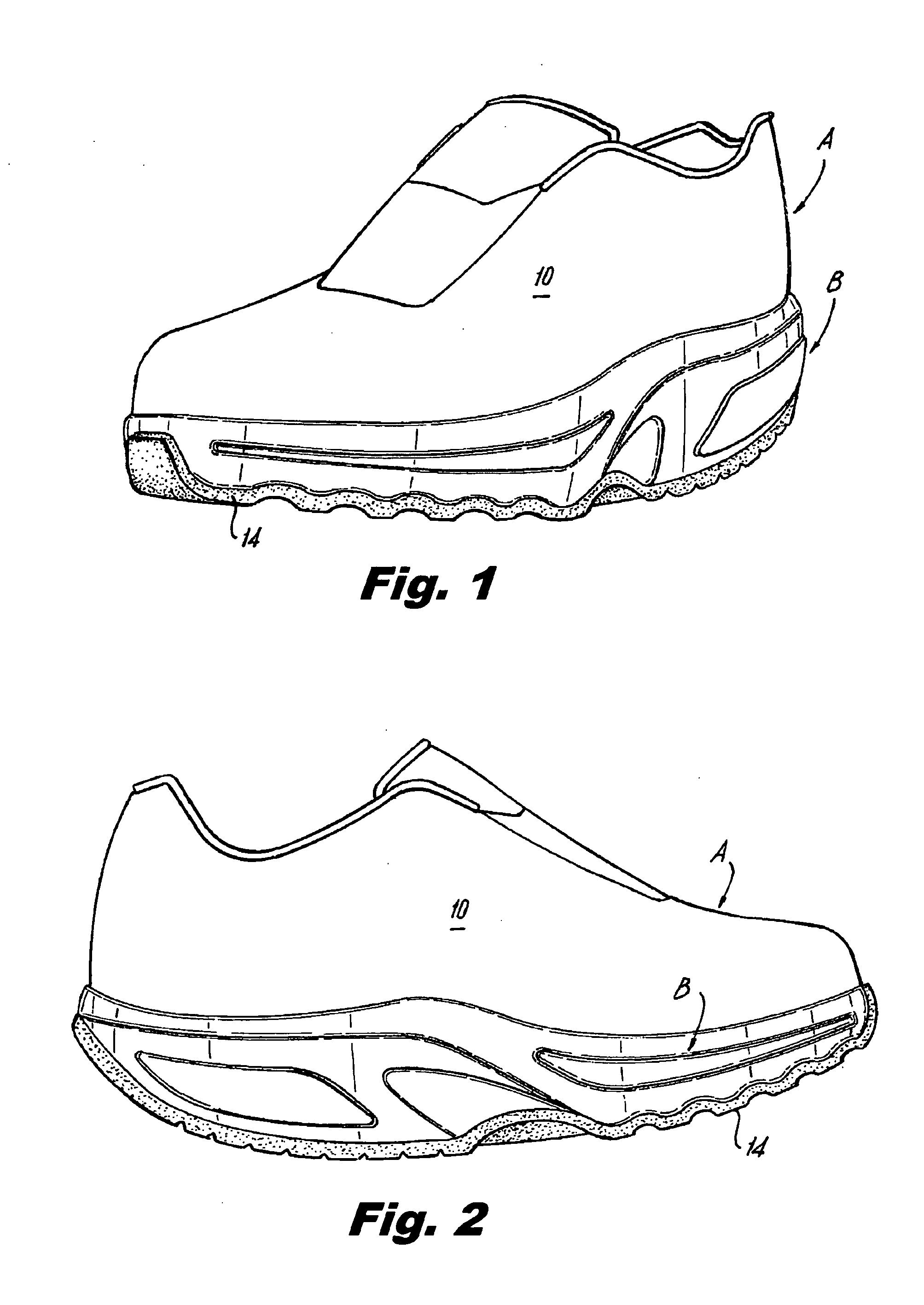

[0050]FIGS. 1 and 2 illustrate a typical footwear product, generally designated A, incorporating the dual-density EVA mid-sole of the present invention, generally designated B. The mid-sole B of the present invention can be formed in whatever shape and size that may be appropriate for footwear product A and with whatever exterior contours and surface features desired. Accordingly, the particular mid-sole design and footwear product style shown in the drawings should not be considered in any way as a limitation on the scope of the present invention but instead simply as a means of illustrating a typical mid-sole B resulting from the fabrication process of the present invention and a typical footwear product A that might incorporate such a mid-sole.

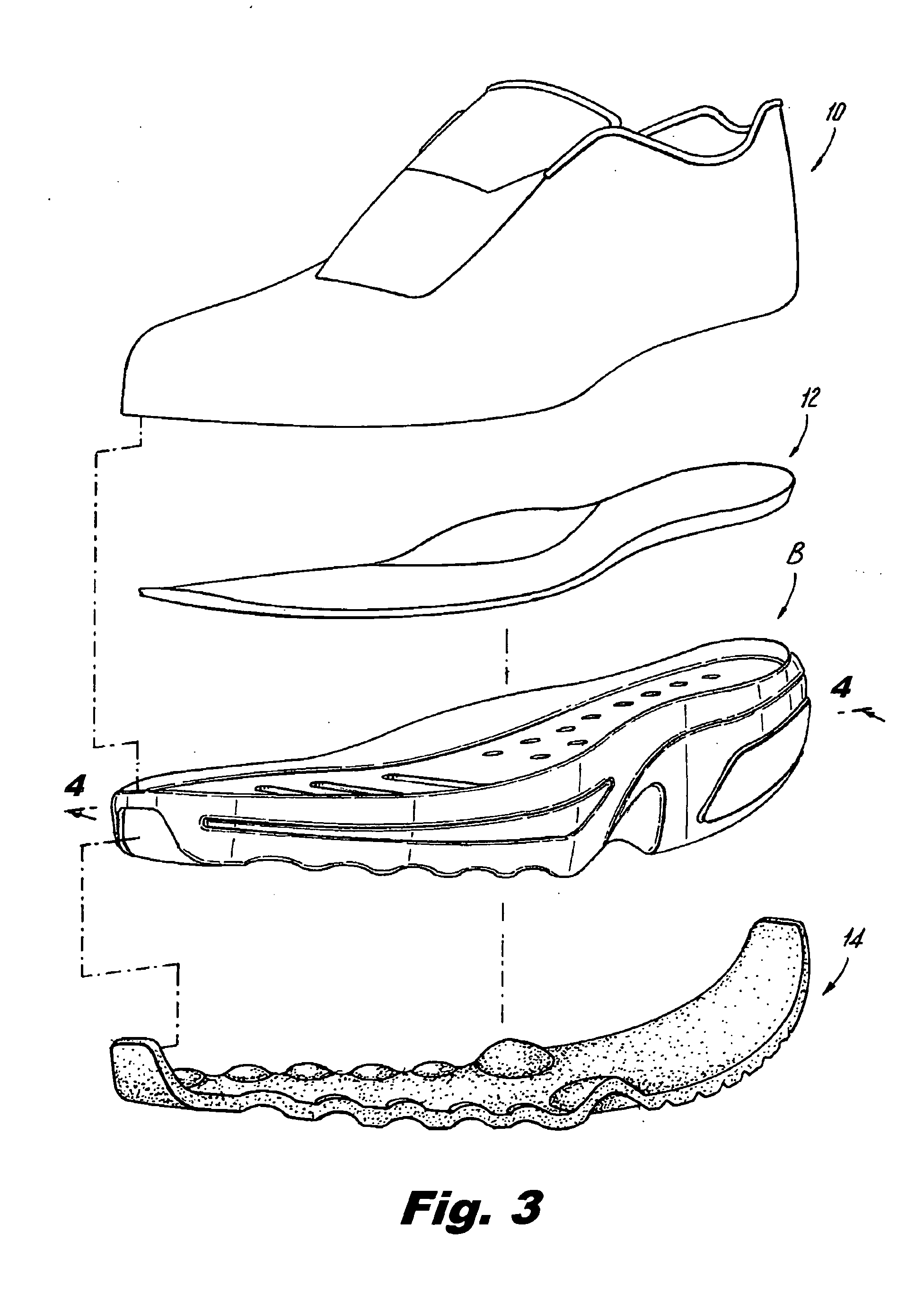

[0051]FIG. 3 shows the components of footwear product A in exploded form. Product A consists of an upper 10, an insole 12, mid-sole B and an outsole 14. Upper 10, insole 12 and outsole 14 are all standard components manufactured by any one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com