Golf club head processing method and golf club head

a golf club and processing method technology, applied in the field of golf club head processing method and golf club head, can solve the problem of adverse influence on the accuracy of the formed scoreline, and achieve the effect of reducing the adverse influen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

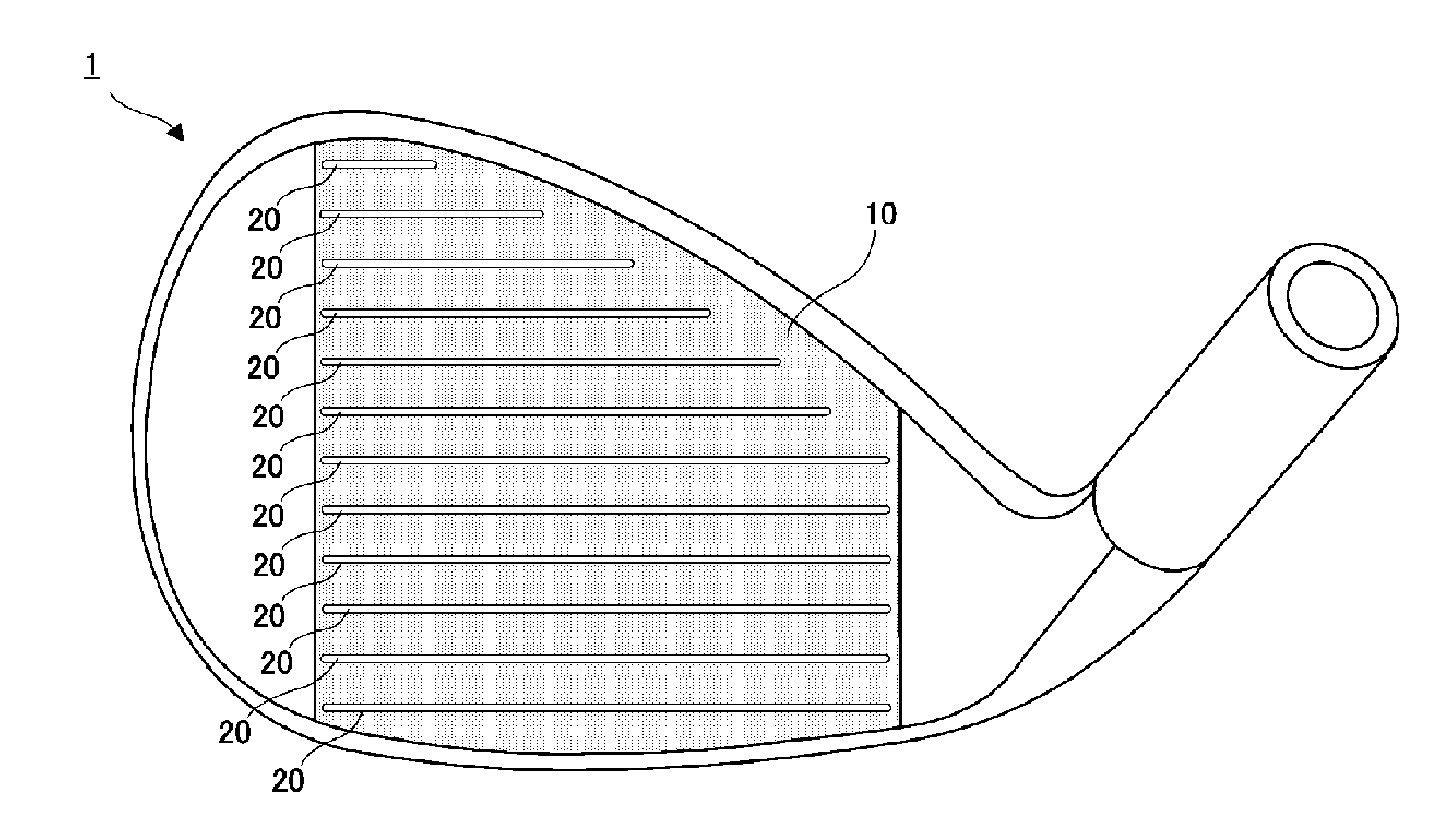

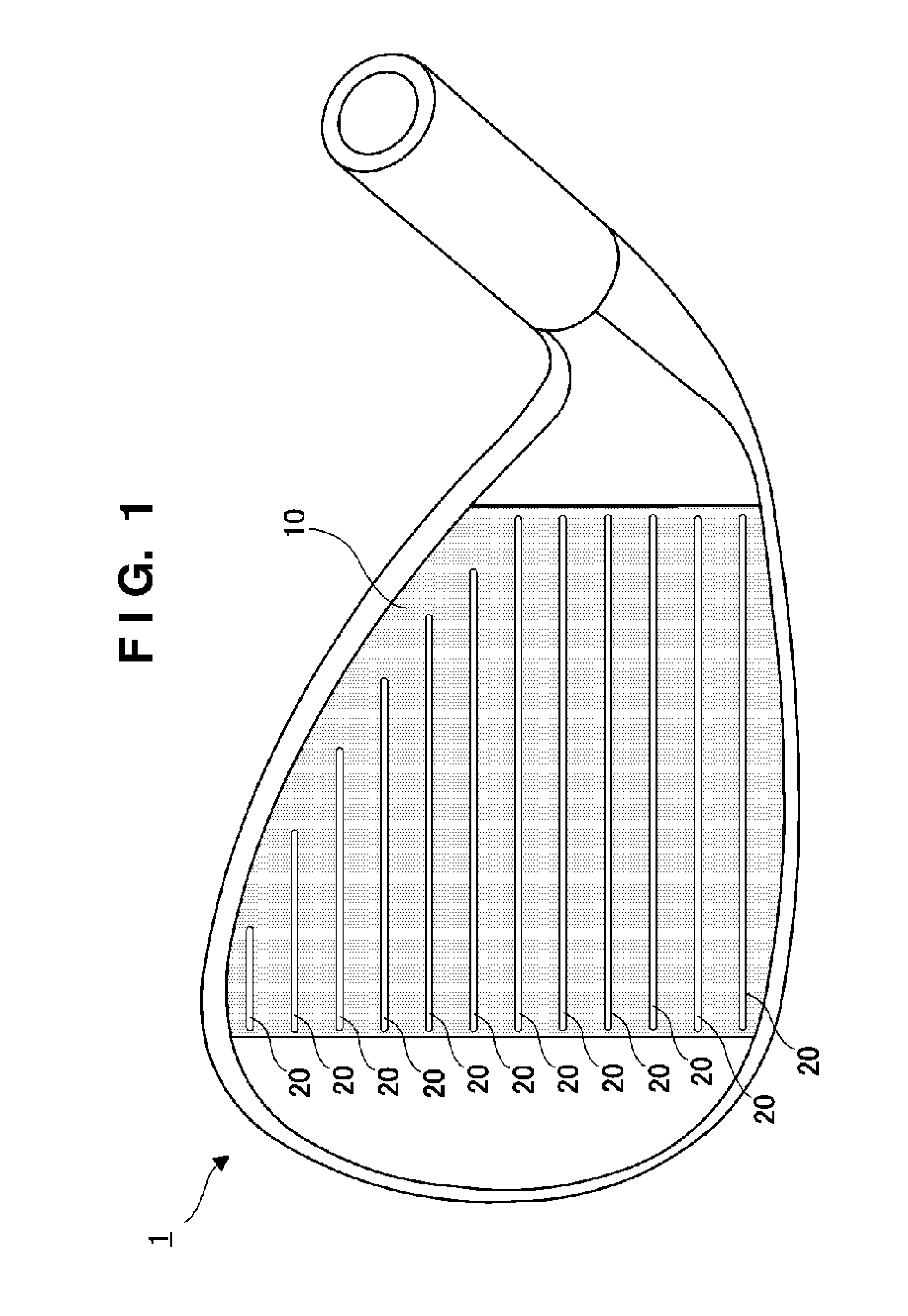

FIG. 1 is an external view of a golf club head 1 according to one embodiment of the present invention. FIG. 1 illustrates an example in which the present invention is applied to an iron type golf club head. The present invention is suitable for an iron type golf club head and, more particularly, for middle iron, short iron, and wedge type golf club heads. More specifically, the present invention is suitable for a golf club head with a loft angle of 30° (inclusive) to 70° (inclusive) and a head weight of 240 g (inclusive) to 320 g (inclusive). However, the present invention is also applicable to wood type and utility (hybrid) type golf club heads.

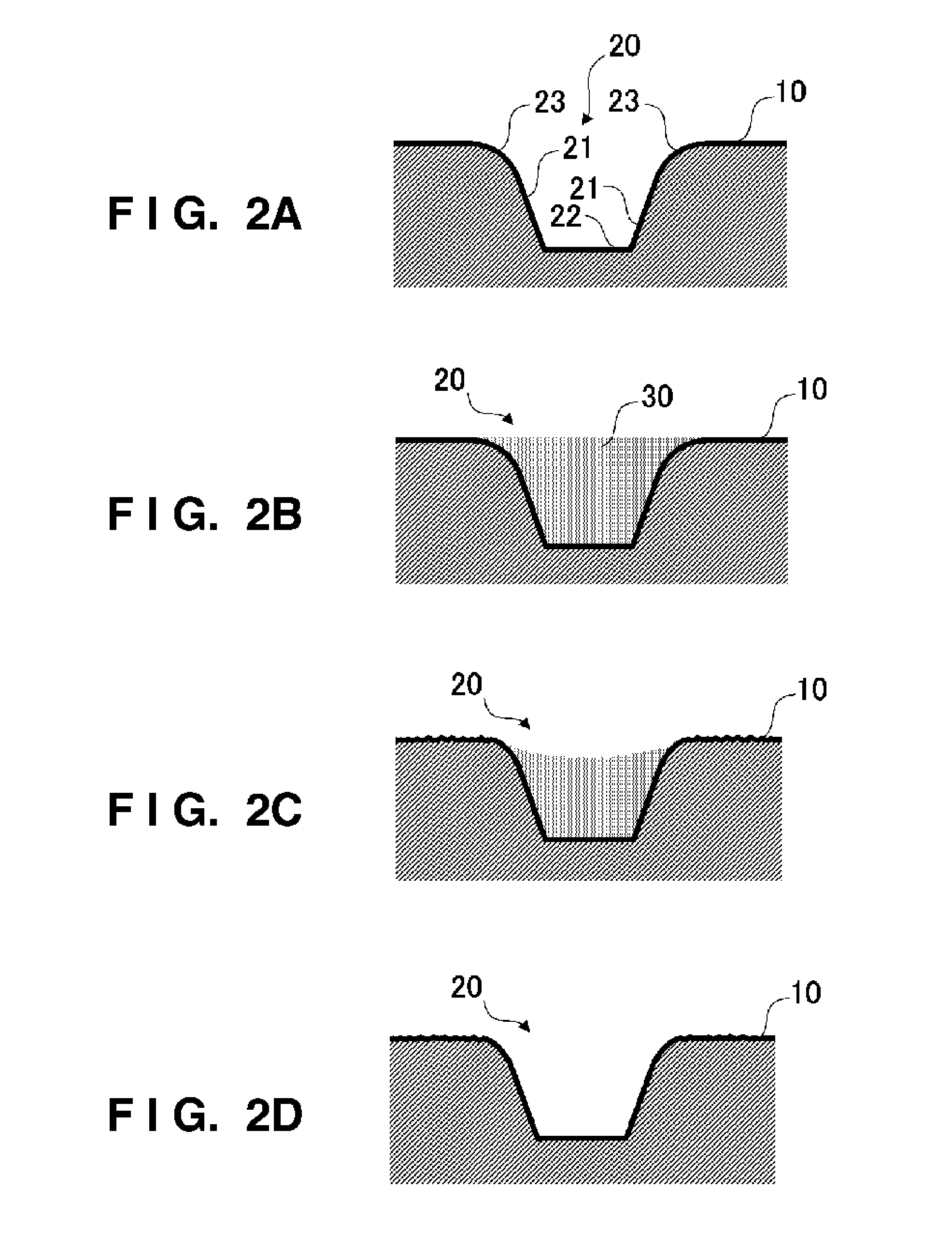

The golf club head 1 has a plurality of scorelines 20 formed in its face surface (striking surface) 10. The scorelines 20 are parallel linear grooves extending in the toe-to-heel direction. Although the scorelines 20 are aligned at an equal pitch in this embodiment, they may be aligned at different pitches.

The face surface 10 is roughened by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| arithmetic average roughness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| arithmetic average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com