Cleaner for Medical Device

a technology for cleaning devices and medical devices, applied in the field of medical devices, can solve the problems of requiring cleaning and decontamination of the end of the luer connector, exposing the connector to debris and contamination,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

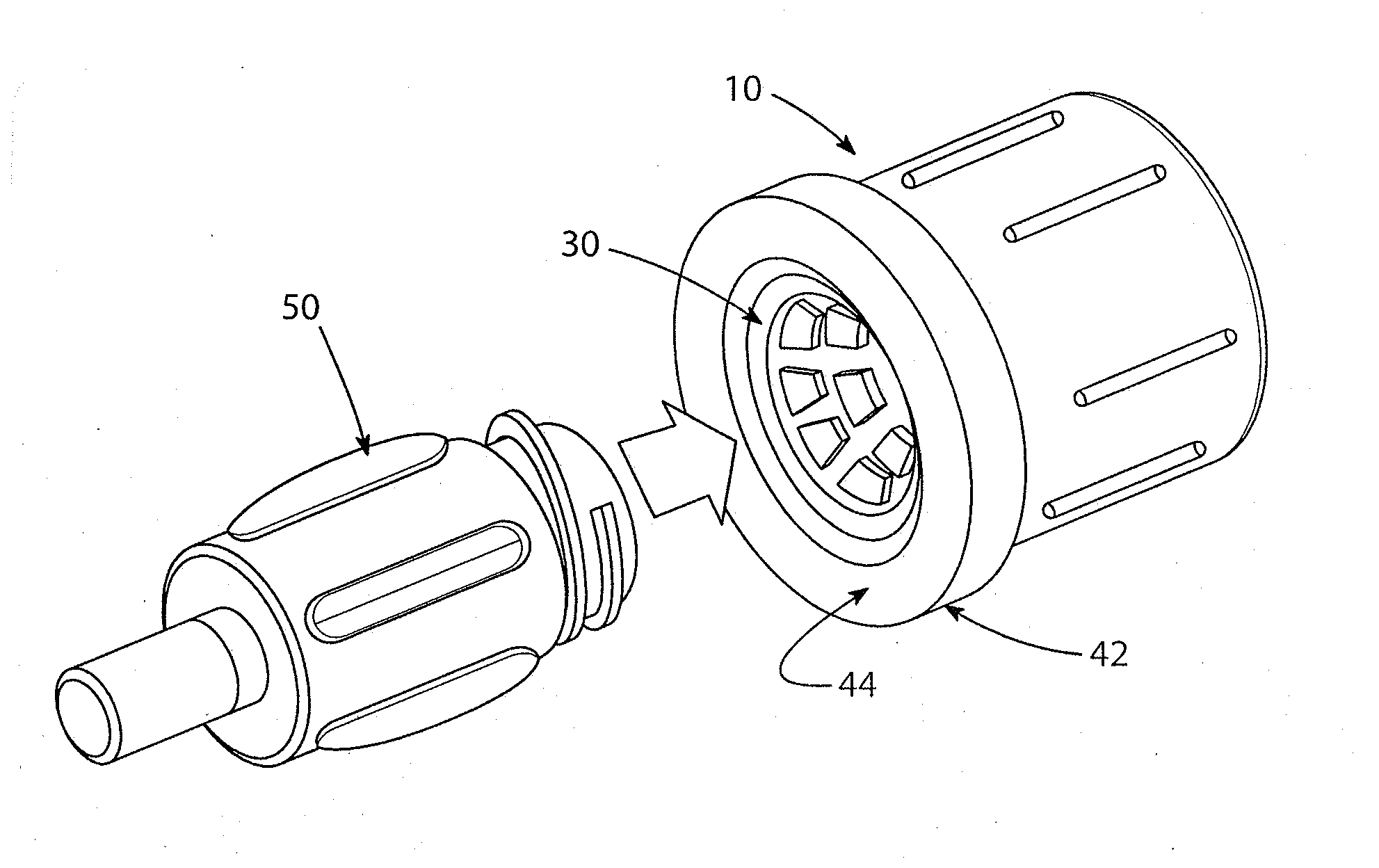

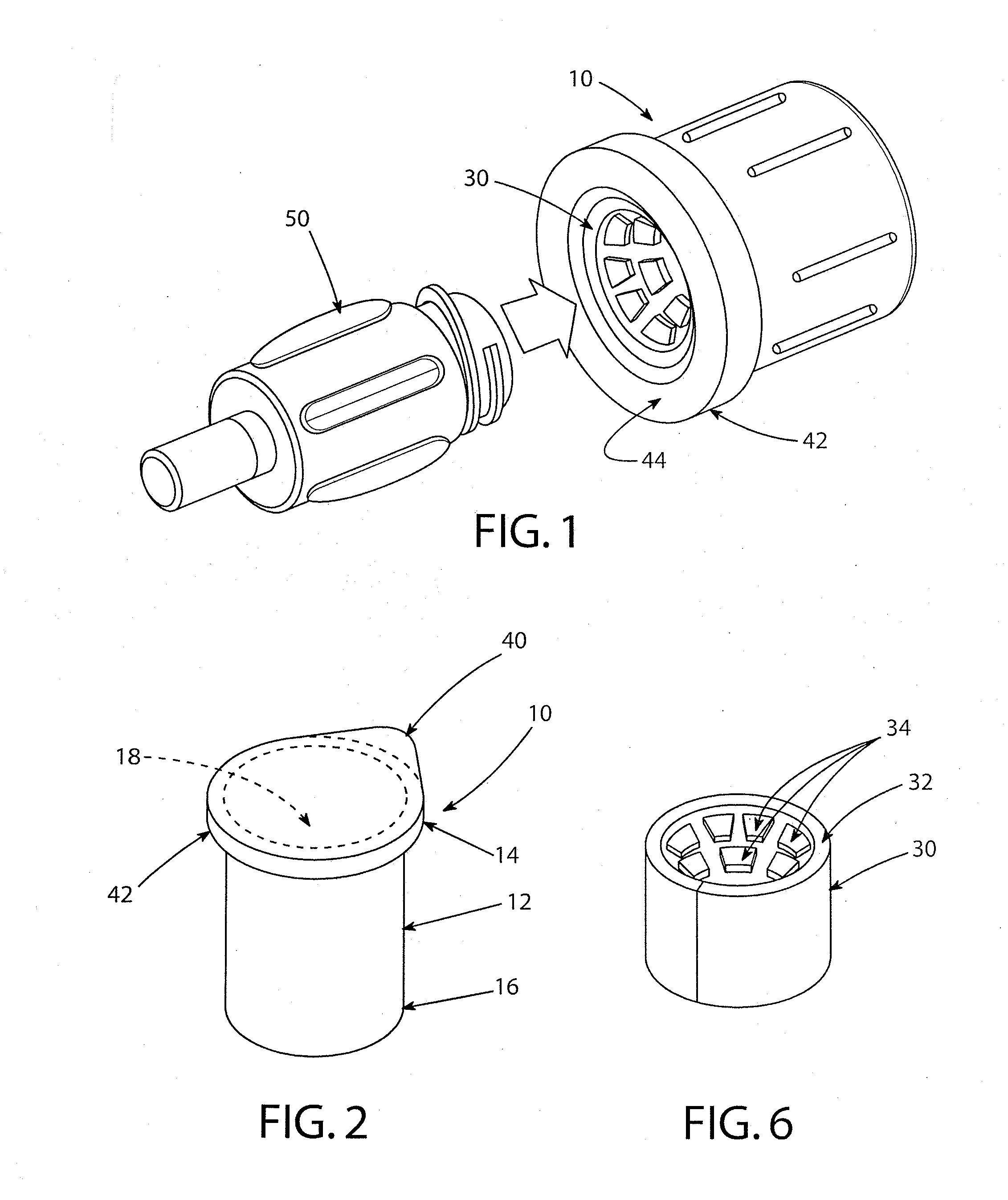

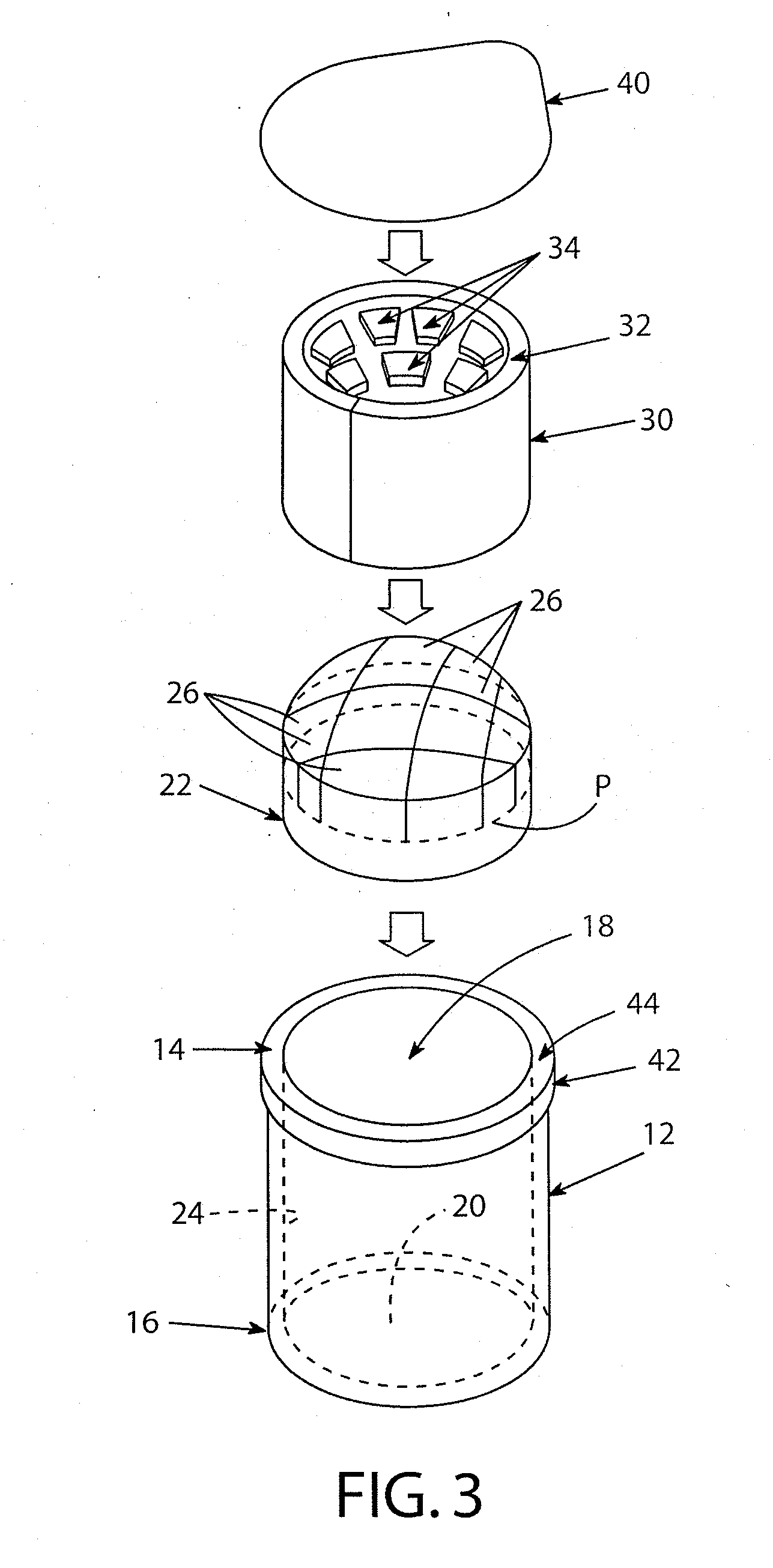

[0027]Second scrubber component 30 is depicted in FIGS. 3 to 7 in a It may preferably be formed of an integral or one-piece rectangular body 32 that is generally flat and rather thin, as seen in FIG. 7, and which is then curled up and installed within the housing 12 down to the proximal end of first scrubber component 22 to extend circumferentially around the cavity proximate the proximal housing end 14, such as by use of a bonding agent such as LOCTITE (trademark of Henkle North America) cyanoacrylate or other acrylic adhesive, or an epoxy adhesive. Second scrubber component 30 defines an array of flexible projections 34 that upon installation in the housing, project radially inwardly. Adjacent the body 32, the flexible projections may have any suitable configuration or shape such as a rectangular cross-section as shown, and the projections may vary in length within the same array. The end portions of the flexible projections 34 will engage the exterior surfaces of the end portion...

second embodiment

[0028]Flexible projections 34 of second scrubber component 30 may be blunt-ended as shown in FIGS. 3 to 7, or, as is seen in FIG. 8 in a second embodiment, the flexible projections 36 of component 30′ may be point-shaped; both shapes may be used in the same array, as well as any other suitable shape or configuration. The end portions of the flexible projections 34,36 will engage the exterior surfaces of the end portion of a medical device inserted into the device-receiving cavity 18 for scrubbing the device end portion. Antimicrobial fluid initially absorbed into the first scrubber component 22 would be expressed therefrom upon insertion of the medical device end portion into the cavity thus compressing the foam material thereof, and the fluid would flow along the second scrubber component and its flexible projections, and the medical device itself, to the exterior surfaces thereof. Materials for the second scrubber component 30 include silicone elastomer, polyurethane, polypropylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com