Hand-held power jigsaw

a power jigsaw and hand-held technology, applied in the field of hand-held jigsaws, can solve the problems of blades going astray, requiring a large amount of practice, and requiring additional work, and achieve the effect of simple and inexpensive fashion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

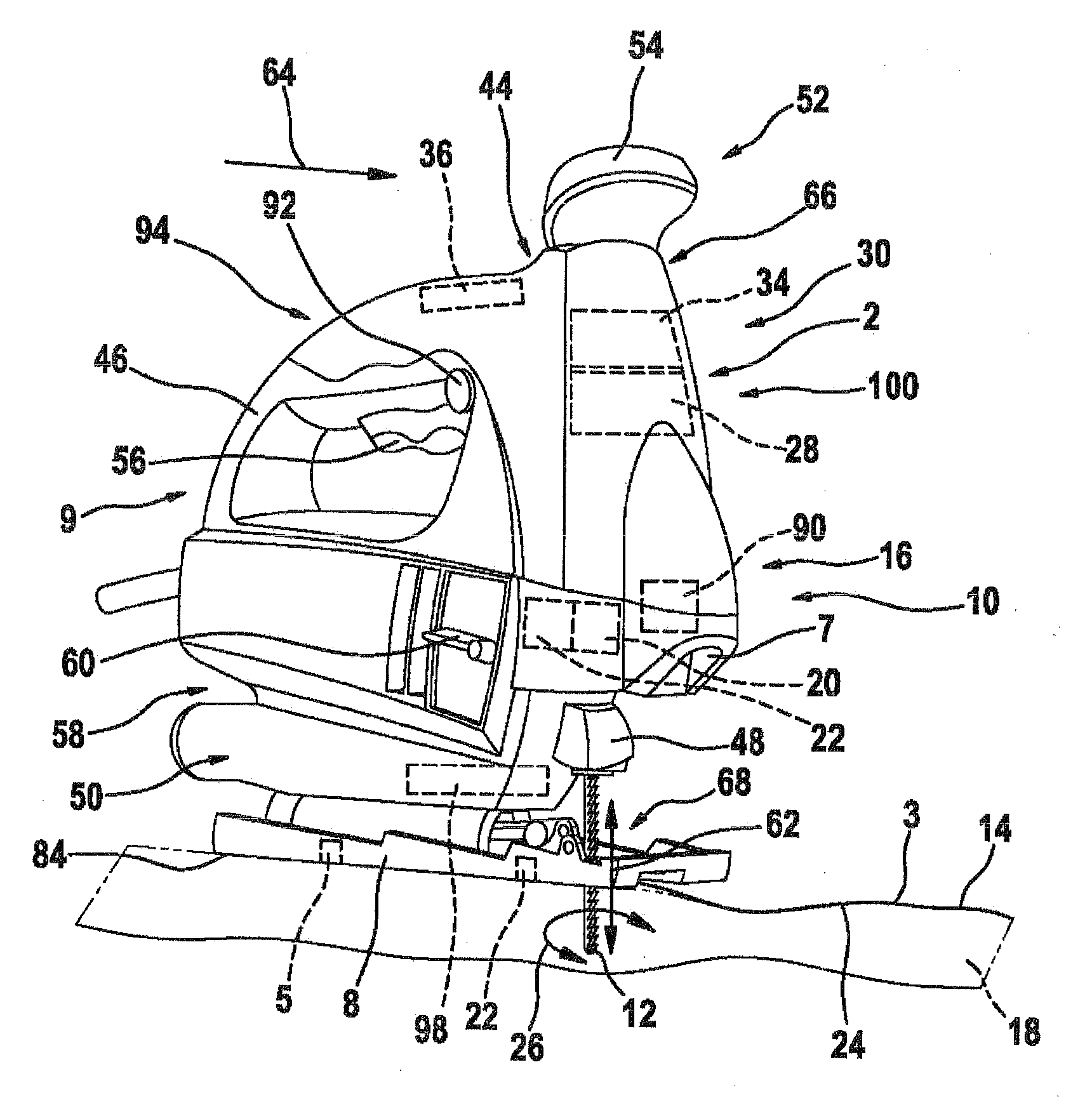

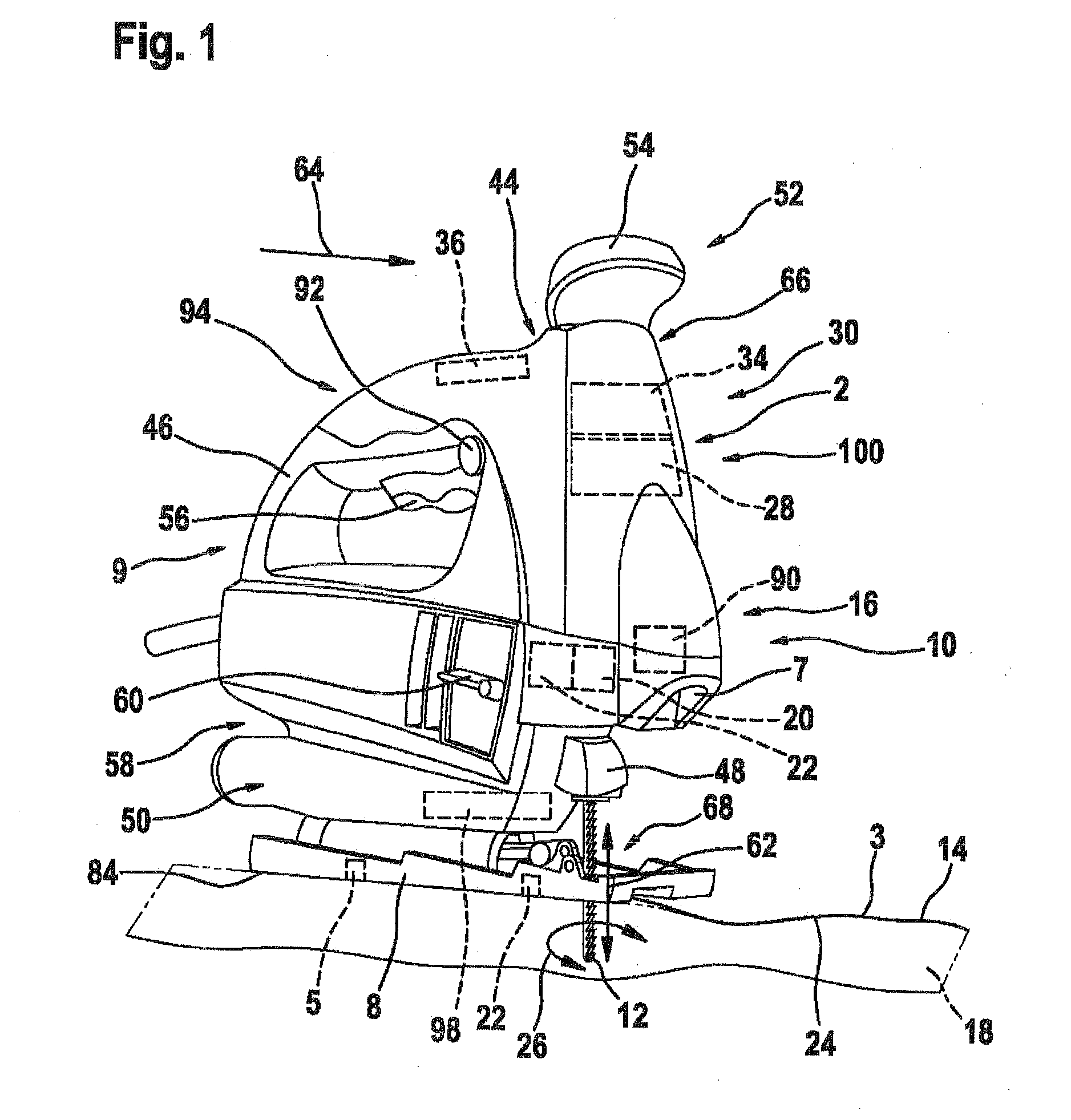

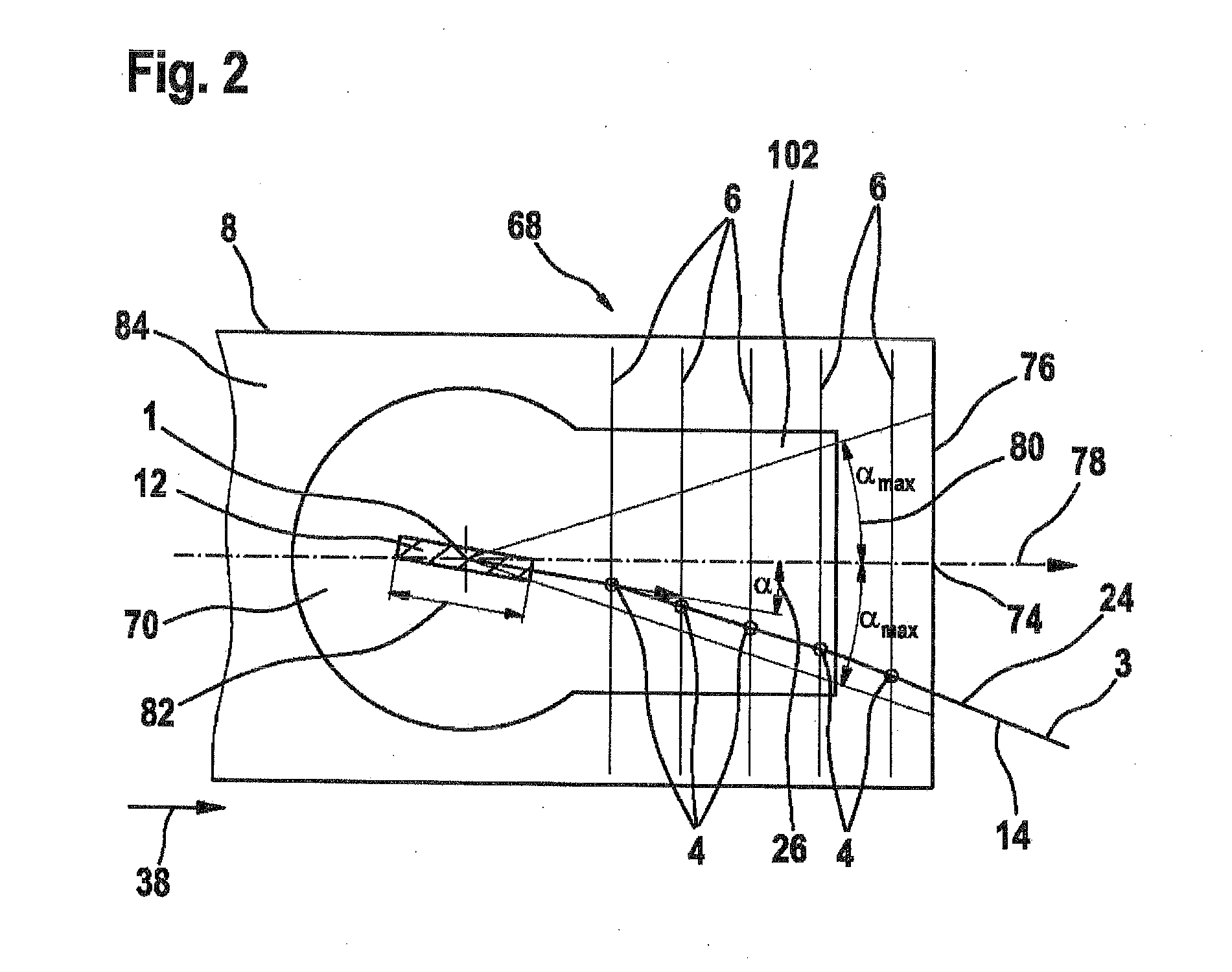

[0022]FIG. 1 is a perspective side view of a hand-held jigsaw 9 according to the invention, embodied in the form of a scrolling jigsaw. The hand-held jigsaw 9 includes a machine housing 44, a main handle 46 integrated into the machine housing 44, and a tool socket 48 containing a tool in the form of a rotatably supported saw blade 12. A glide element or glide shoe 8 in the form of a base plate is situated on a side 50 oriented toward the work piece 18 to be machined. This glide shoe 8 permits the hand-held jigsaw 9 to advantageously glide on the work piece 18. On the side 52 oriented away from the saw blade 12, in a region that can be associated with the main handle 46, a guide knob is provided, which is used for an at least manual guidance of the hand-held jigsaw 9. The machine housing 44 also contains a motor that is not shown in detail. On the main handle 46, an actuation switch 56 is provided, which can be used to switch the hand-held jigsaw 9 on and off. In a side region 58 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| blade angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com