Dual Chamber Passive Retraction Needle Syringe

a passive retraction and needle syringe technology, applied in the field of syringe assemblies, can solve the problems of inadvertent activation of the retraction feature, increased complexity of the sealing plunger and stopper, and device inadvertent activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]Before describing several exemplary embodiments of the invention, it is to be understood that the invention is not limited to the details of construction or process steps set forth in the following description. The invention is capable of other embodiments and of being practiced or being carried out in various ways.

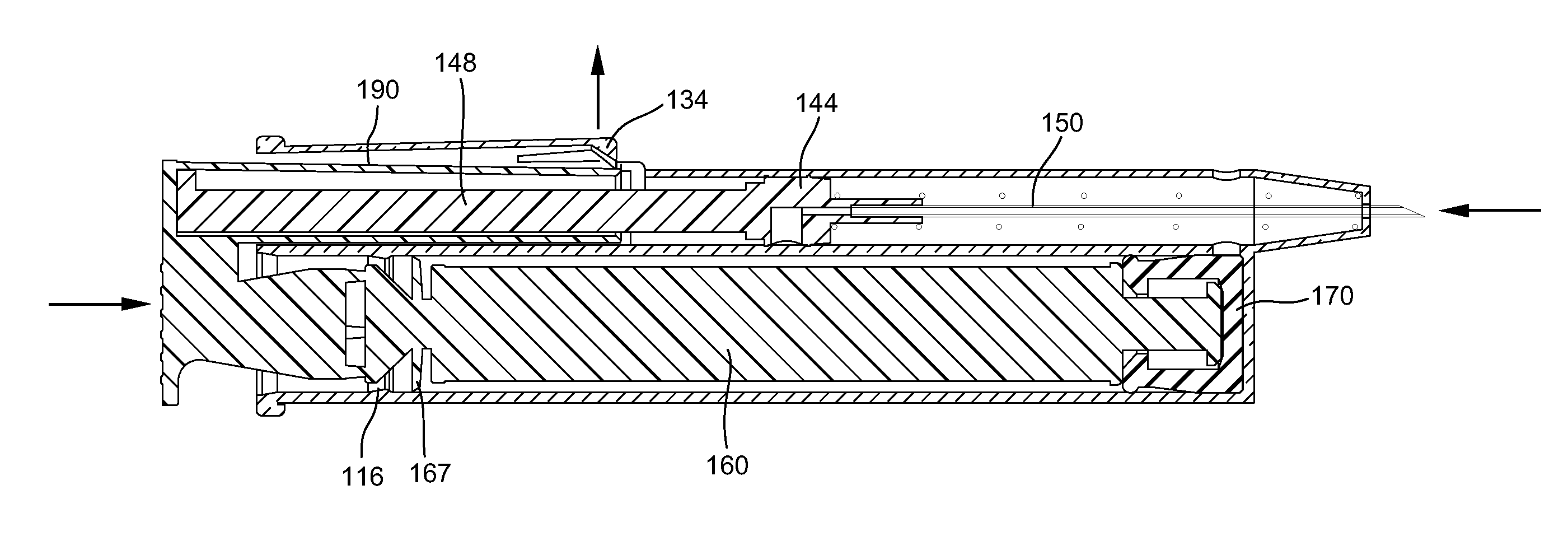

[0053]In this disclosure, a convention is followed wherein the distal end of the device is the end closest to a patient and the proximal end of the device is the end away from the patient and closest to a practitioner.

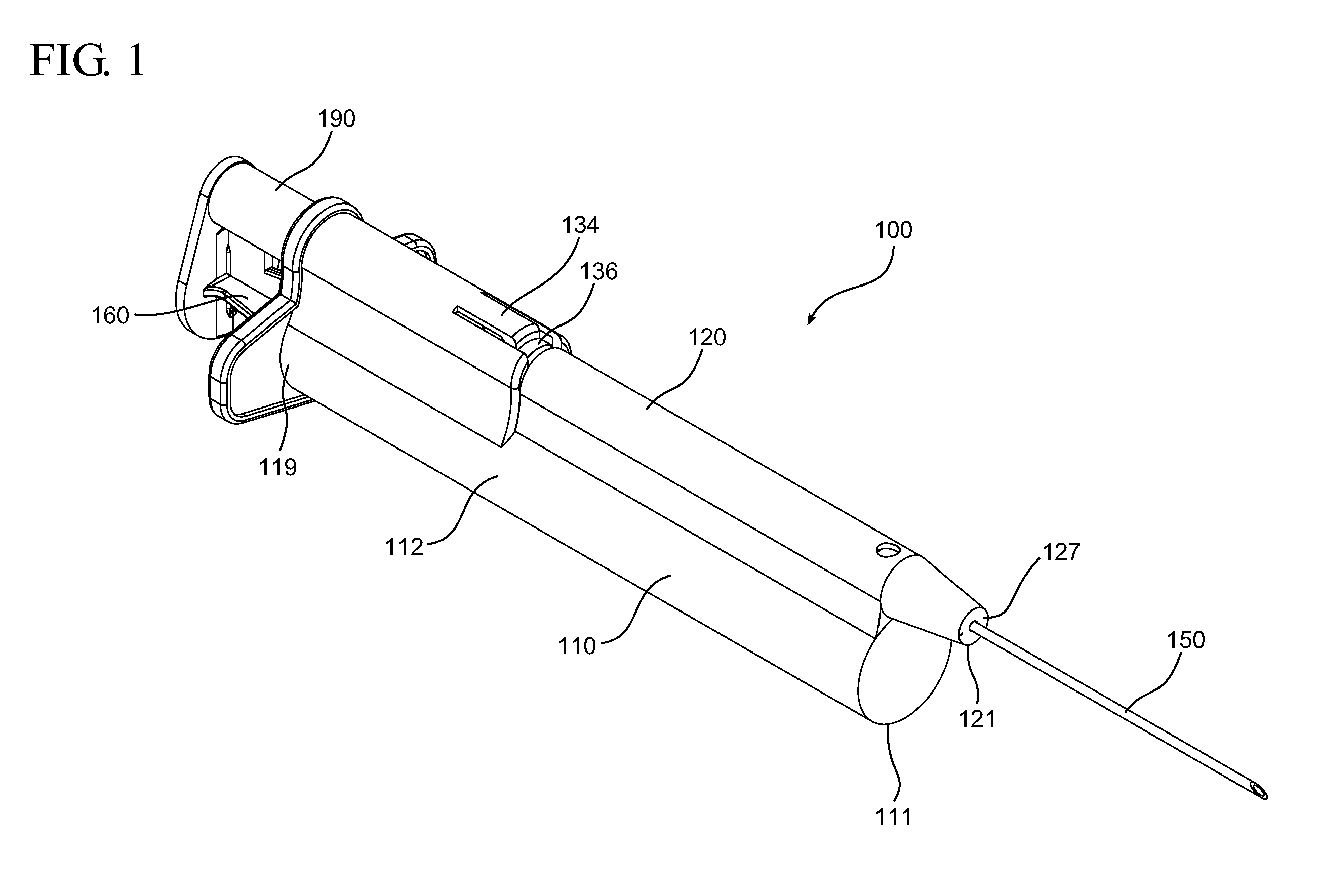

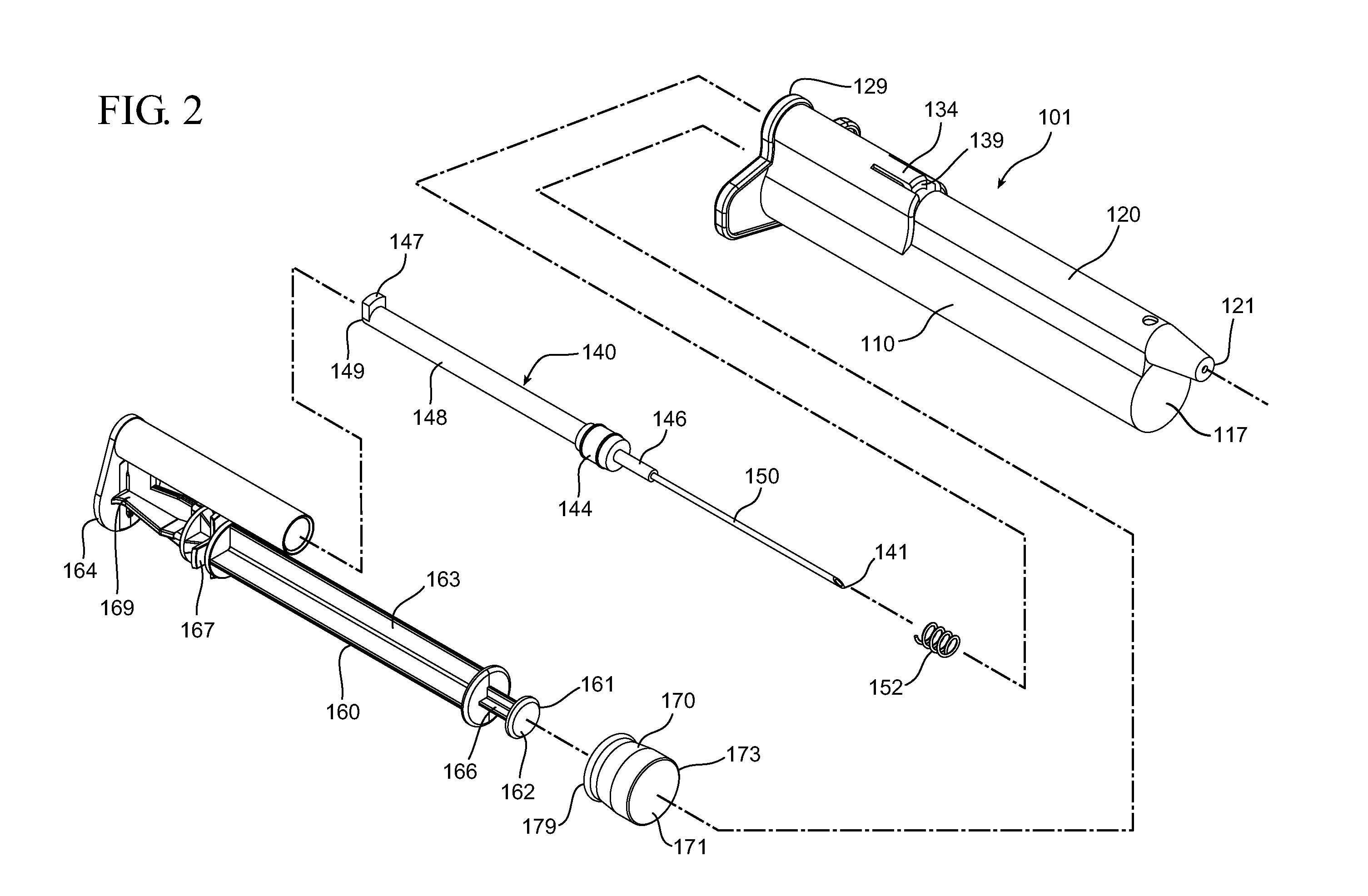

[0054]A first aspect of the present invention pertains to a retractable syringe assembly having a passive retraction feature. The retractable syringe assembly 100 of one or more embodiments utilizes a dual syringe barrel or a syringe barrel that isolates the fluid chamber from the retraction feature.

[0055]In the embodiment shown in FIGS. 1-11, the retractable syringe assembly includes a dual syringe barrel 101 that includes fluid barrel 110 and a retra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com