Method and apparatus for tempering material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

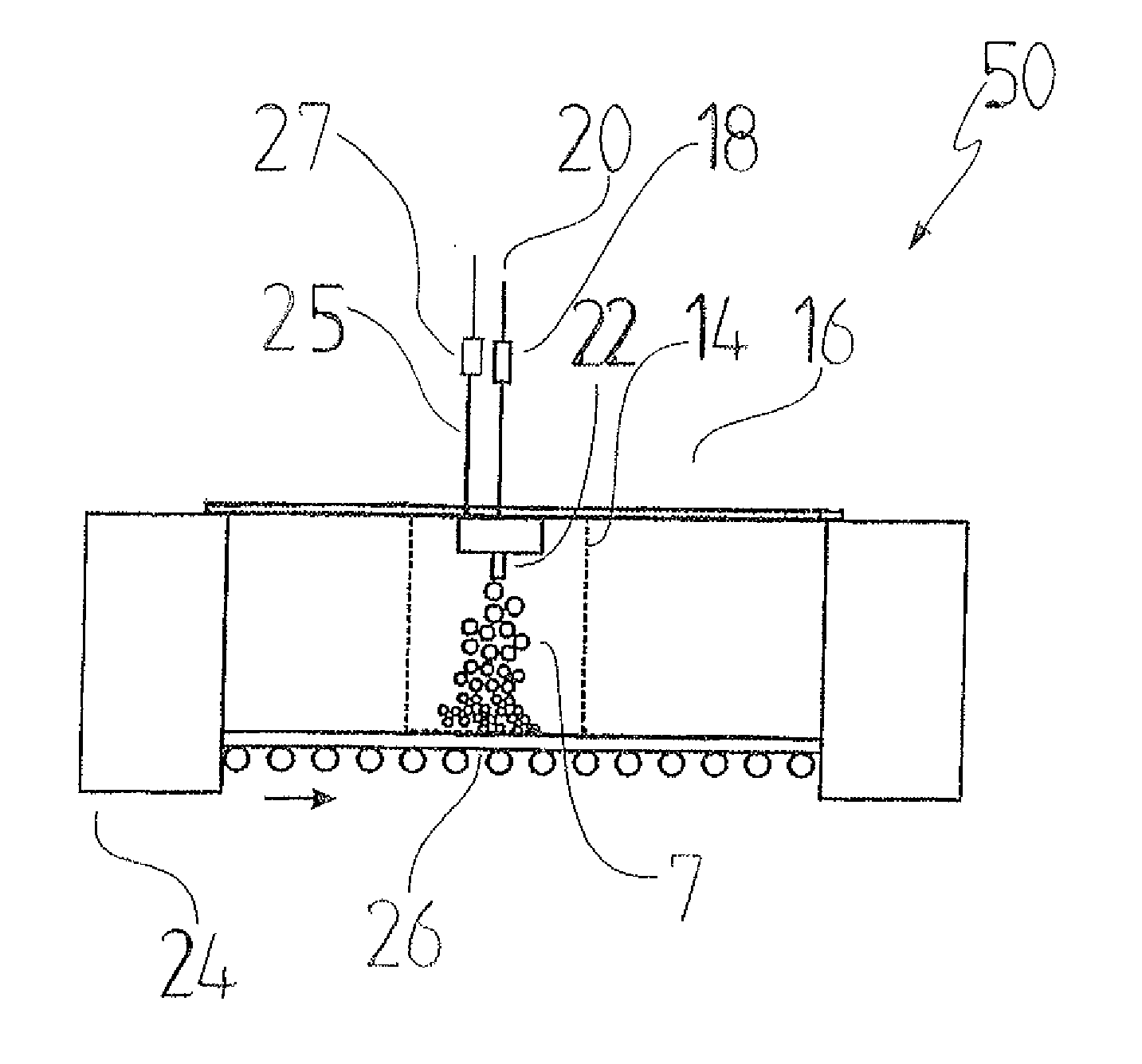

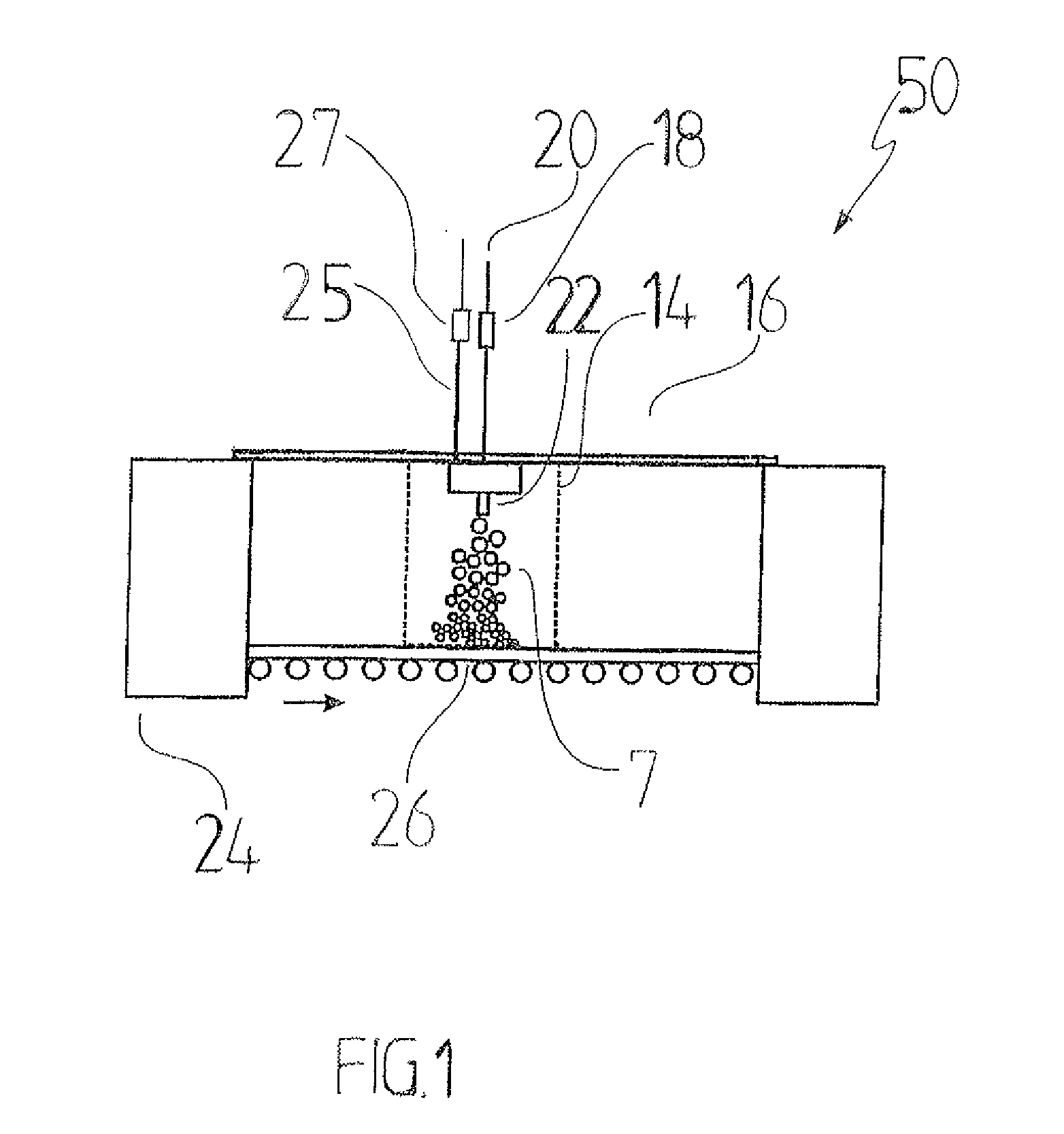

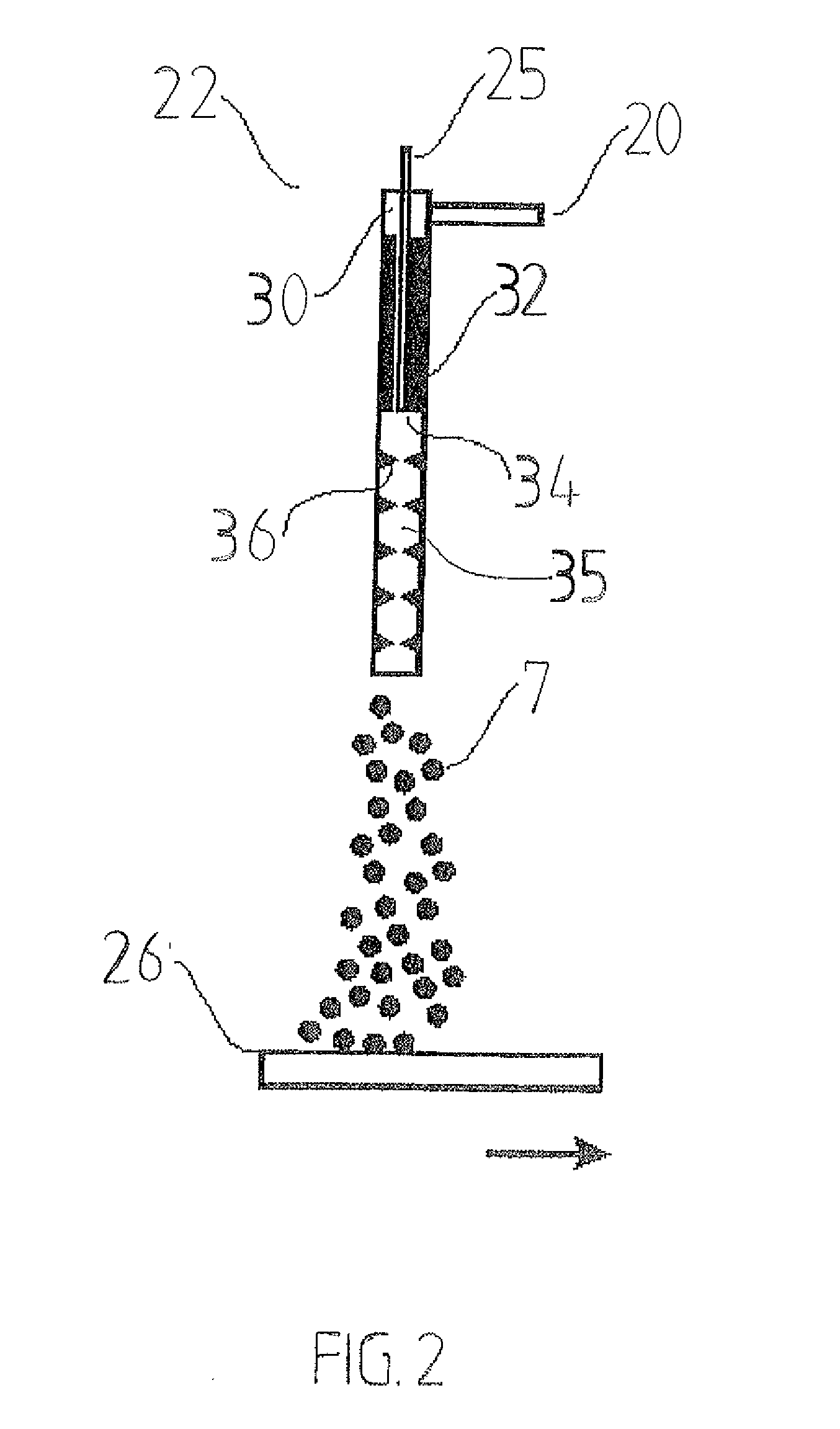

[0013]Reference is made to FIG. 1, which discloses an embodiment of the apparatus of the invention that allows the method of the invention to be implemented. The apparatus 50 is used for tempering a moving hot material web 26. The material to be tempered may be for example metal, such as steel, glass, metal alloy or a ceramic material. Although FIG. 1 shows the tempering of a moving material web, the method and apparatus of the invention may be applied to the tempering of any material or product movable in any way. Alternatively, the material or product to be tempered may also be stationary and one or more sprayers may move. In accordance with the invention the apparatus 50 comprises a sprayer 22 that allows the one or more liquids to be atomized into small droplets. When necessary, the apparatus 50 may also comprise two or more sprayers 22. The liquid to be atomized with the sprayer 22 to be used in tempering is preferably water, although it may also be an alcohol, such as a mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com