Self aligned triple patterning

a triple patterning and self-aligning technology, applied in the field of sequence processing, can solve problems such as inability to reliably form photolithographic techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

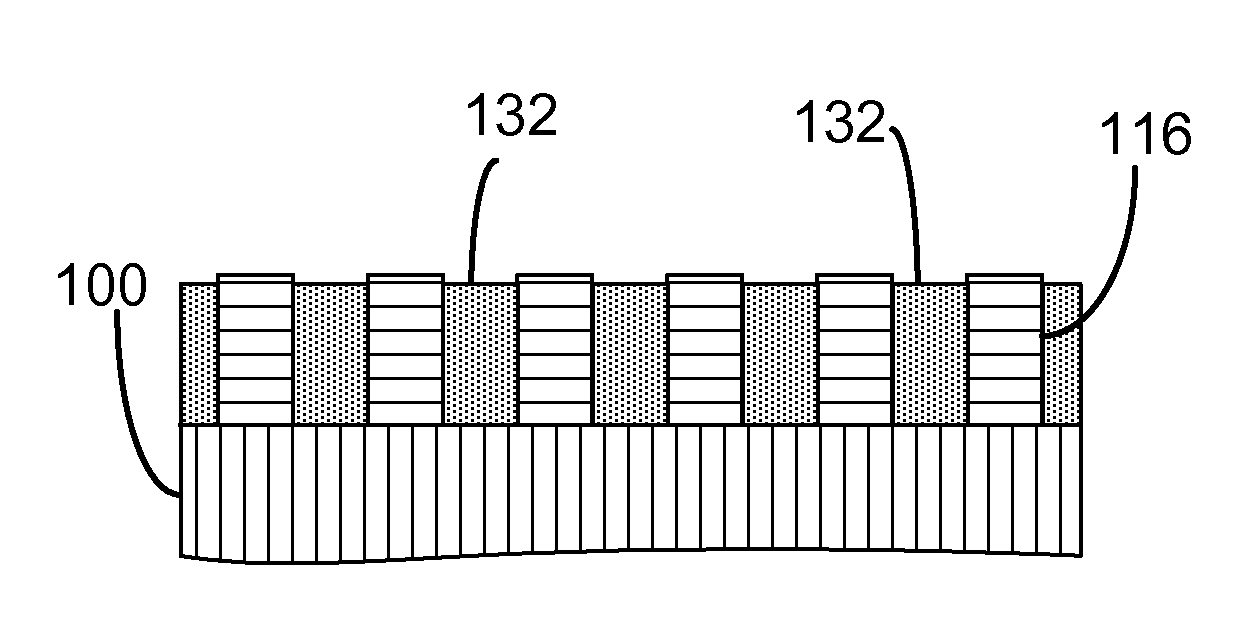

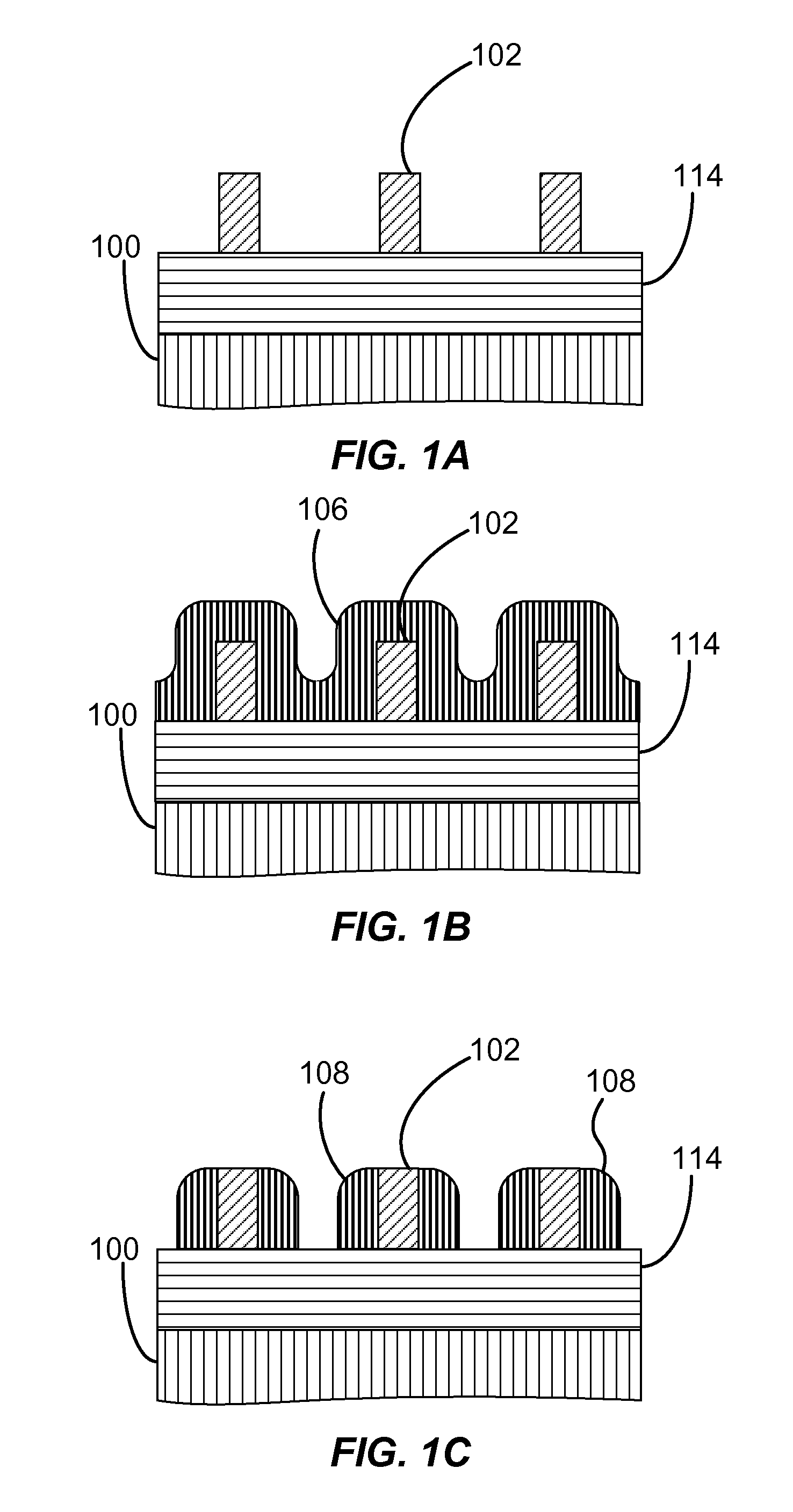

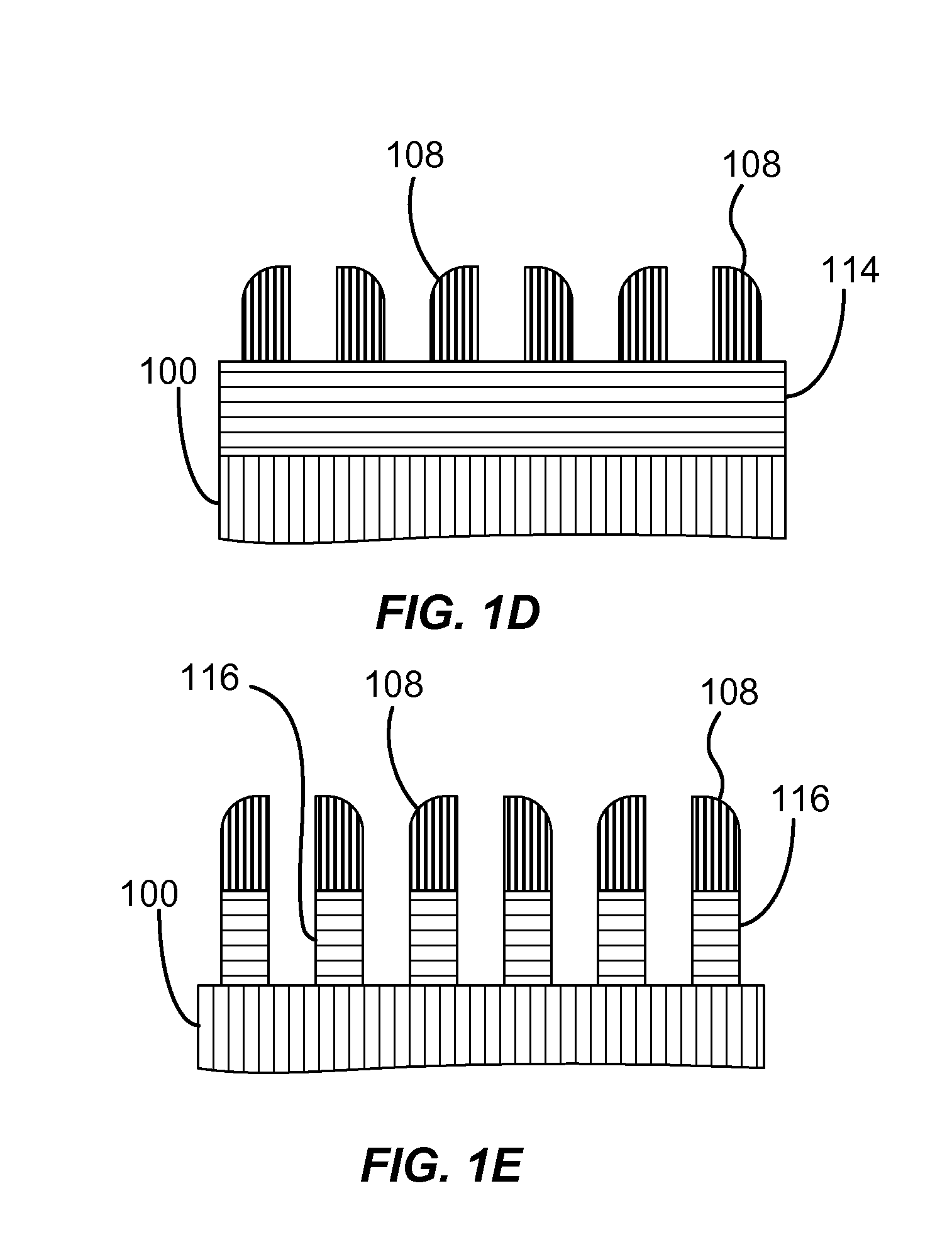

[0015]Embodiments of the present invention pertain to methods of forming features on a substrate using a self-aligned triple patterning (SATP) process. A stack of layers is patterned near the optical resolution of a photolithography system using a high-resolution photomask. The heterogeneous stacks are selectively etched to undercut a hard mask layer beneath overlying cores. A dielectric layer, which is flowable during formation, is deposited and fills the undercut regions as well as the regions between the heterogeneous stacks. The dielectric layer is anisotropically etched and a conformal spacer is deposited on and between the cores. The spacer is anisotropically etched to leave two spacers between each core. The cores are stripped and the spacers are used together with the remaining hard mask features to pattern the substrate at triple the density of the original pattern.

[0016]In order to better understand and appreciate the invention, reference is made to FIG. 2, which is a flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com