Collapsible plastic container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

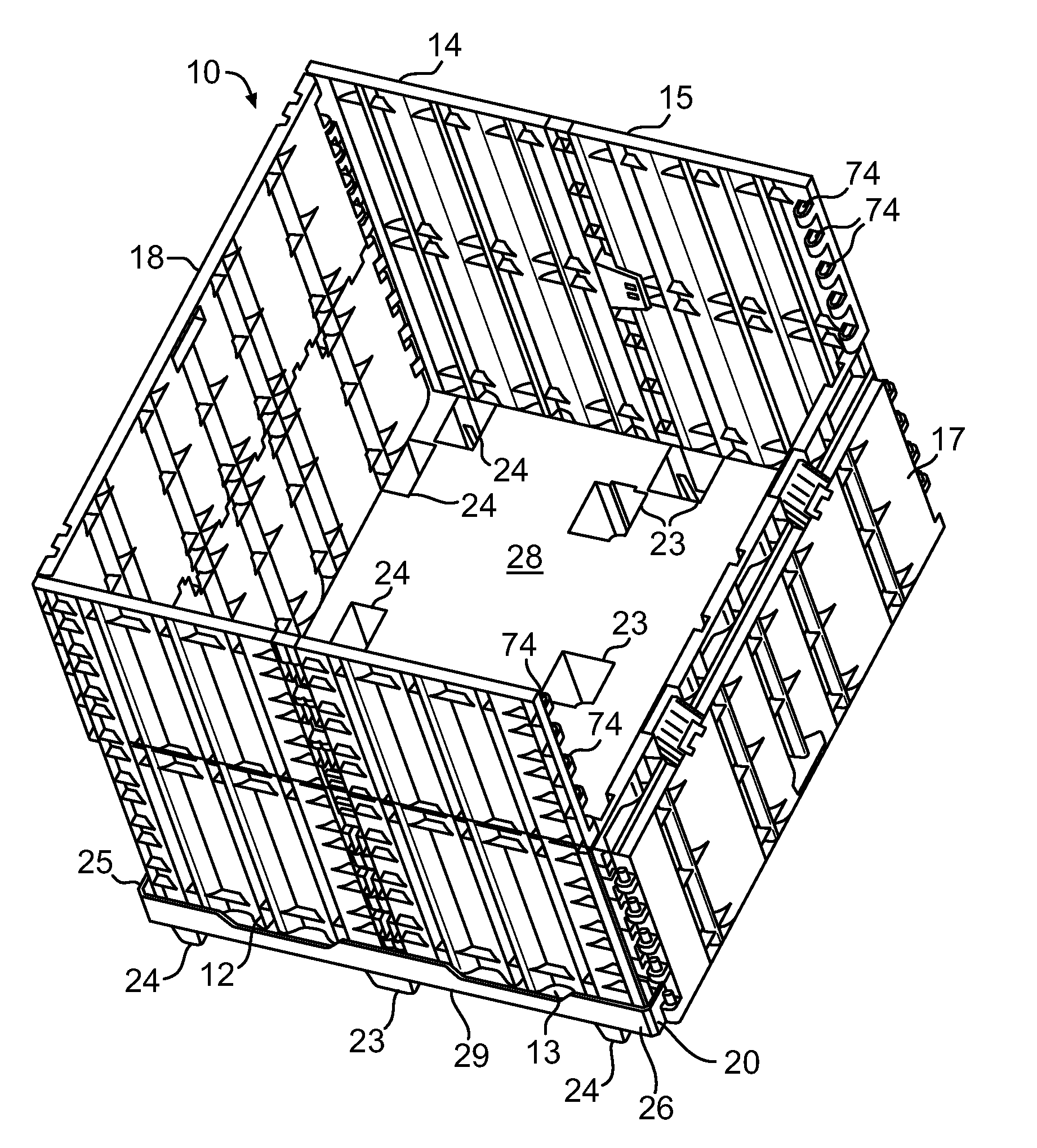

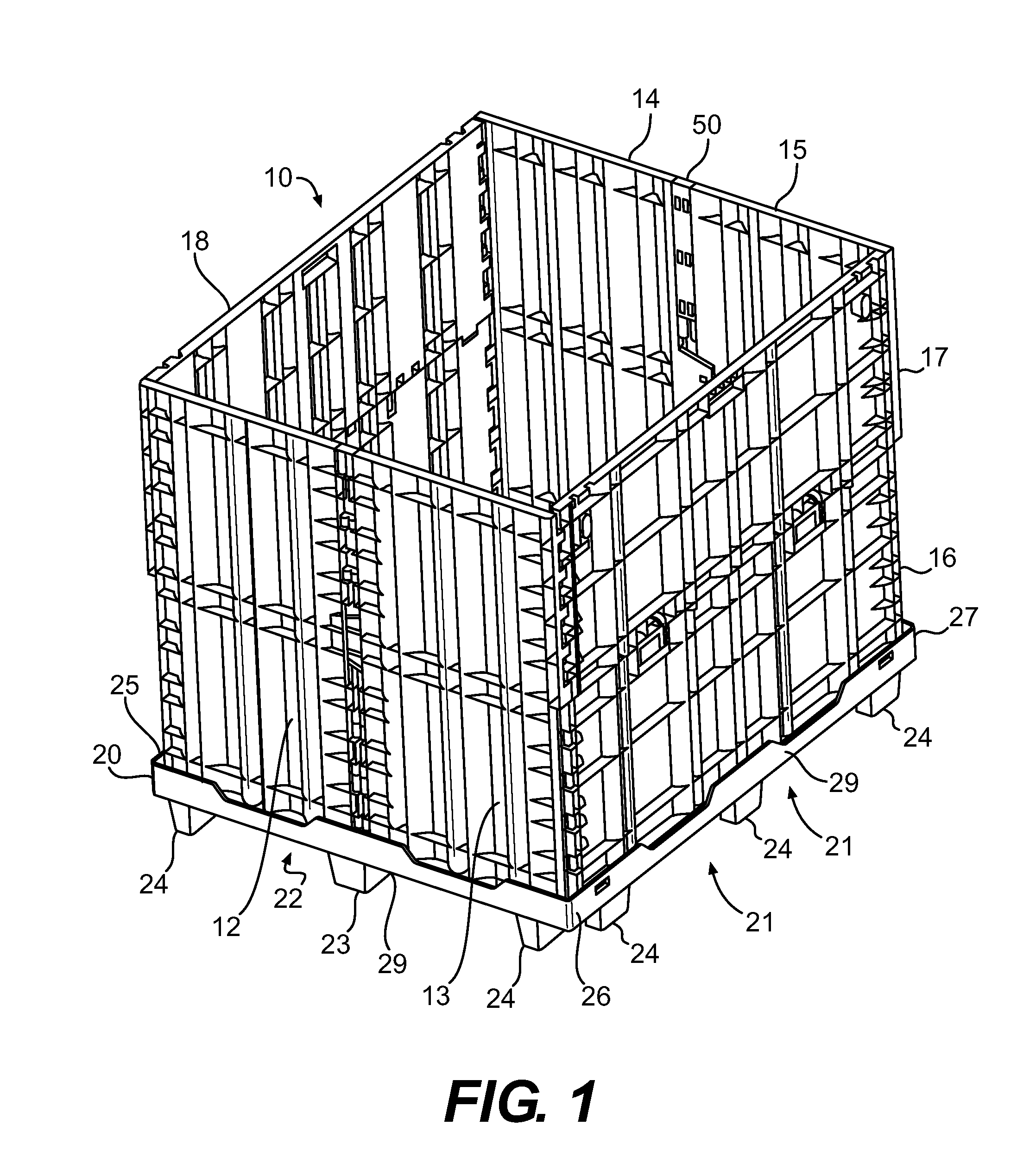

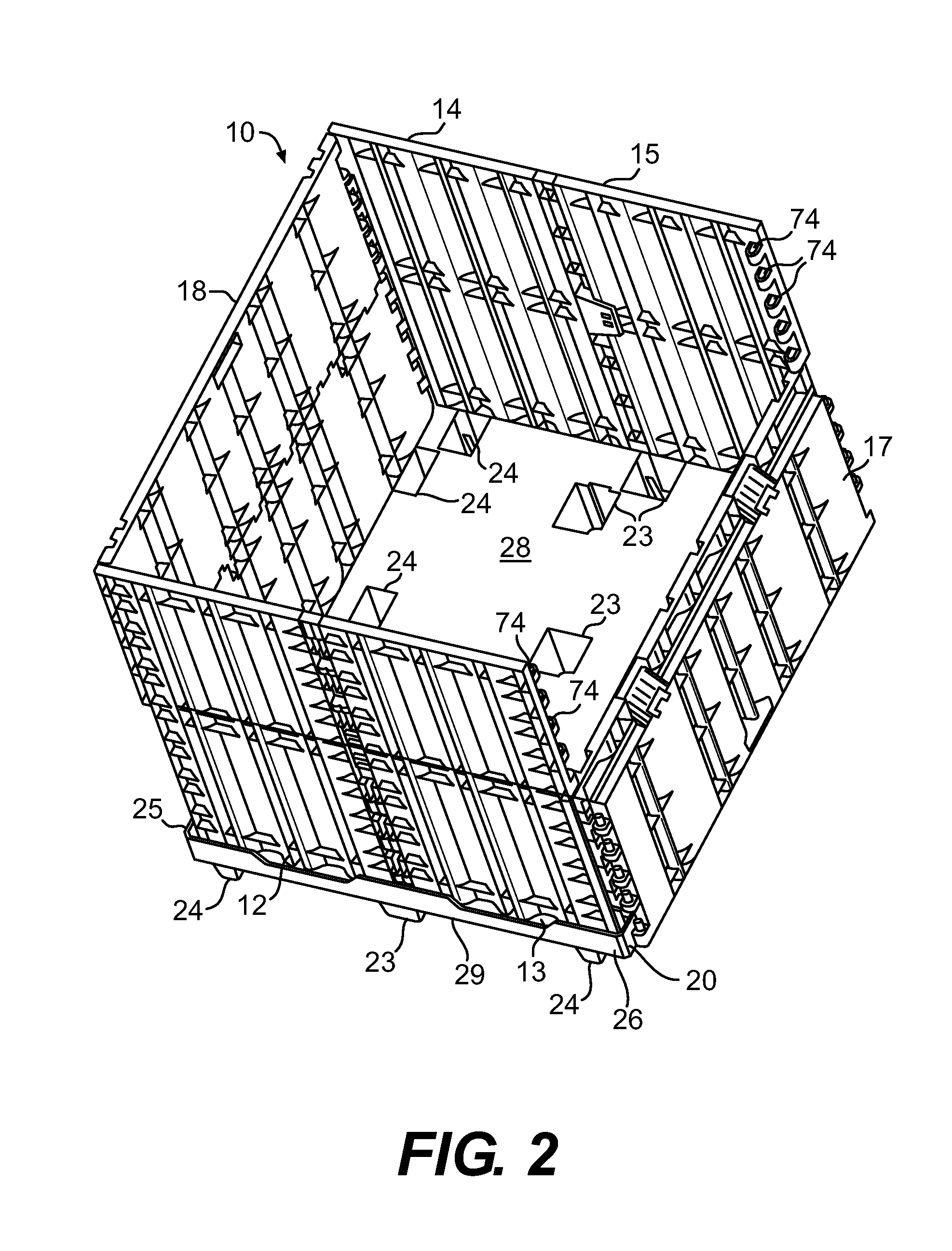

[0026]FIG. 1 shows a collapsible container according to an embodiment of the present invention. The collapsible container 10 has end panels 12 and 13 together forming an end wall and opposed end panels 14 and 15 together forming an end wall. Additionally, a side wall 16 has a gate 17 opposed to side wall 18. The end and side wall panels, and the gate may be plastic and made by injection molding.

[0027]The end and side walls of the container are assembled onto a pallet base 20, which may be plastic and made by injection molding, having forklift entryways 21 along the side wall of the container and 22 along the end wall of the container. Further, the pallet has corners 25 and 26 as well as corner 27 and one corner not shown in FIG. 1. The corners have flanges extending up from a planer base 28, as shown in FIG. 2, of the pallet. Additional mid span flanges 29 are formed between the corners of the periphery of the pallet base 20. Feet 24, shown in FIG. 6, are formed at the corners of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com