Extendible dipper with extruded portion for a backhoe arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

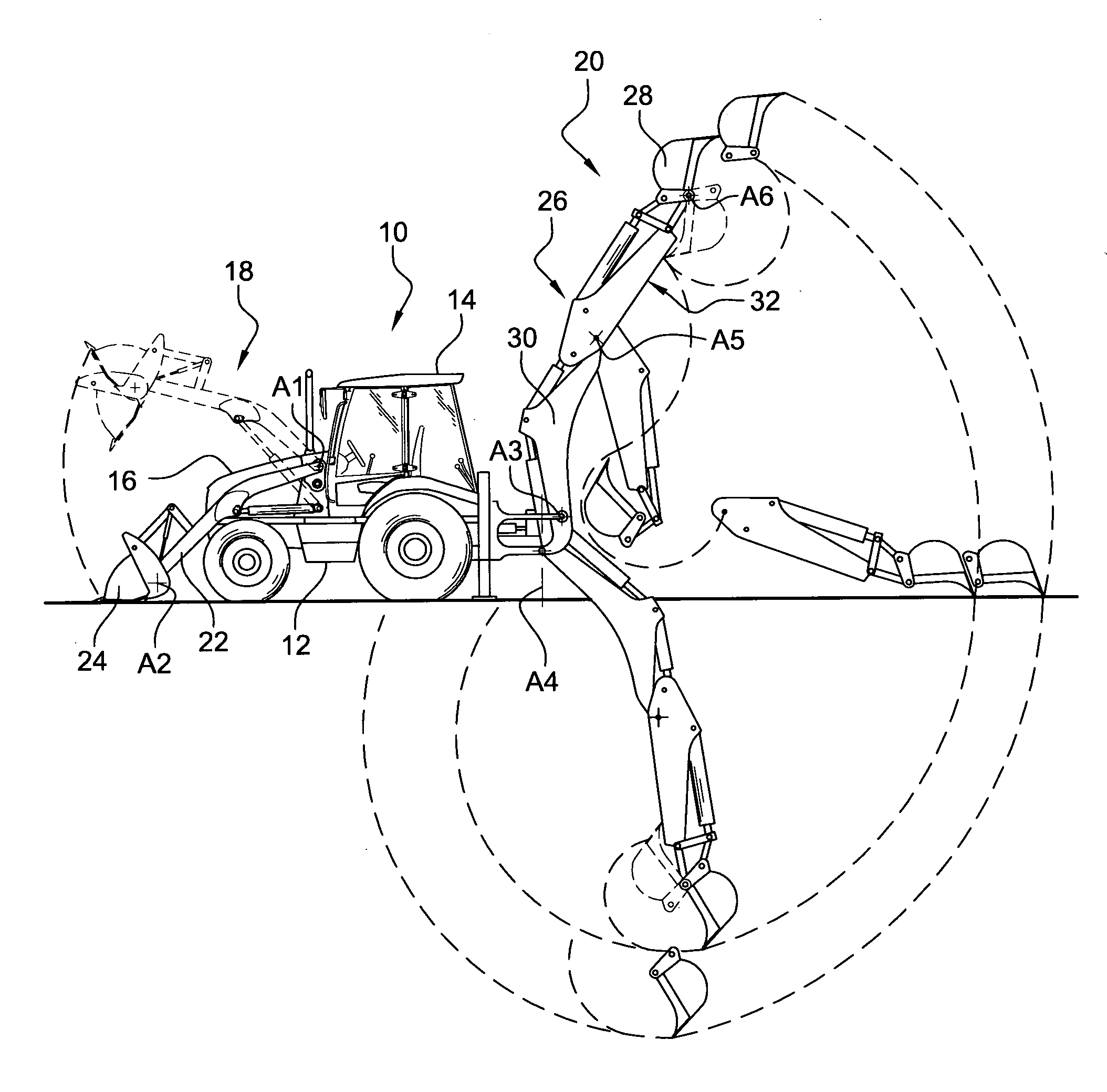

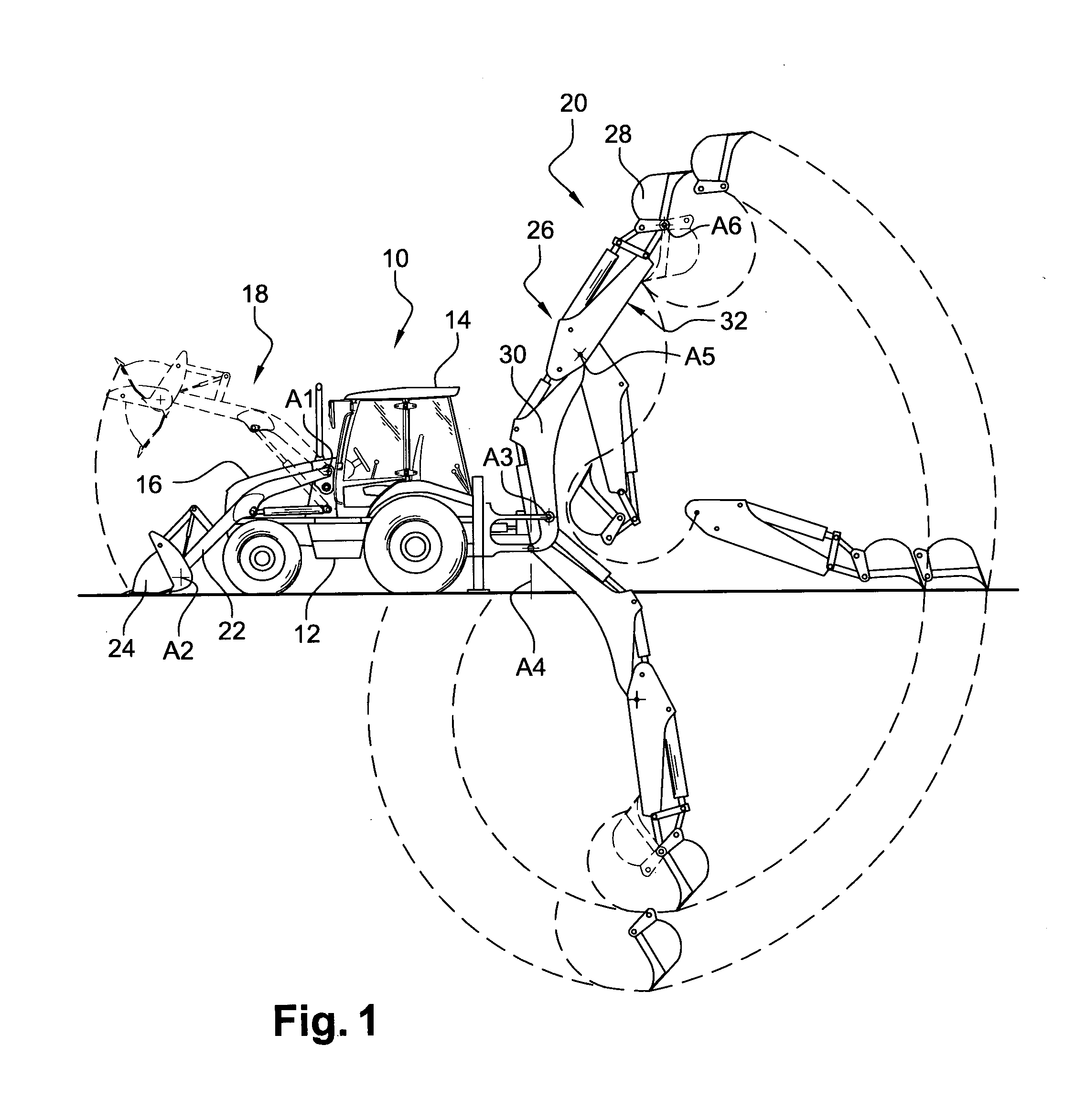

[0013]On FIG. 1 is shown a construction equipment machine 10 of the so-called backhoe-loader type. Such machine comprises a chassis 12 mounted on four wheels and a cabin 14 mounted on the chassis for receiving an operator of the machine. In front of the cabin 14, a bonnet 16 receives the machine's main engine. Such a machine therefore exhibits the main looks of an agricultural tractor. It derives its name from the fact that it carries two main pieces of equipment, namely a loader equipment 18 at the front, and a backhoe equipment 20 at the rear. The loader equipment 18 comprises essentially two loader arms 22 which are articulated on the chassis around a horizontal axis Al near the rear end of the bonnet 16 and which extend longitudinally towards the front on both sides of the bonnet 16. At the free ends of the loader arms, in front of the bonnet 16, a loader bucket 24 having a generally forward facing cavity is articulated around a horizontal axis A2.

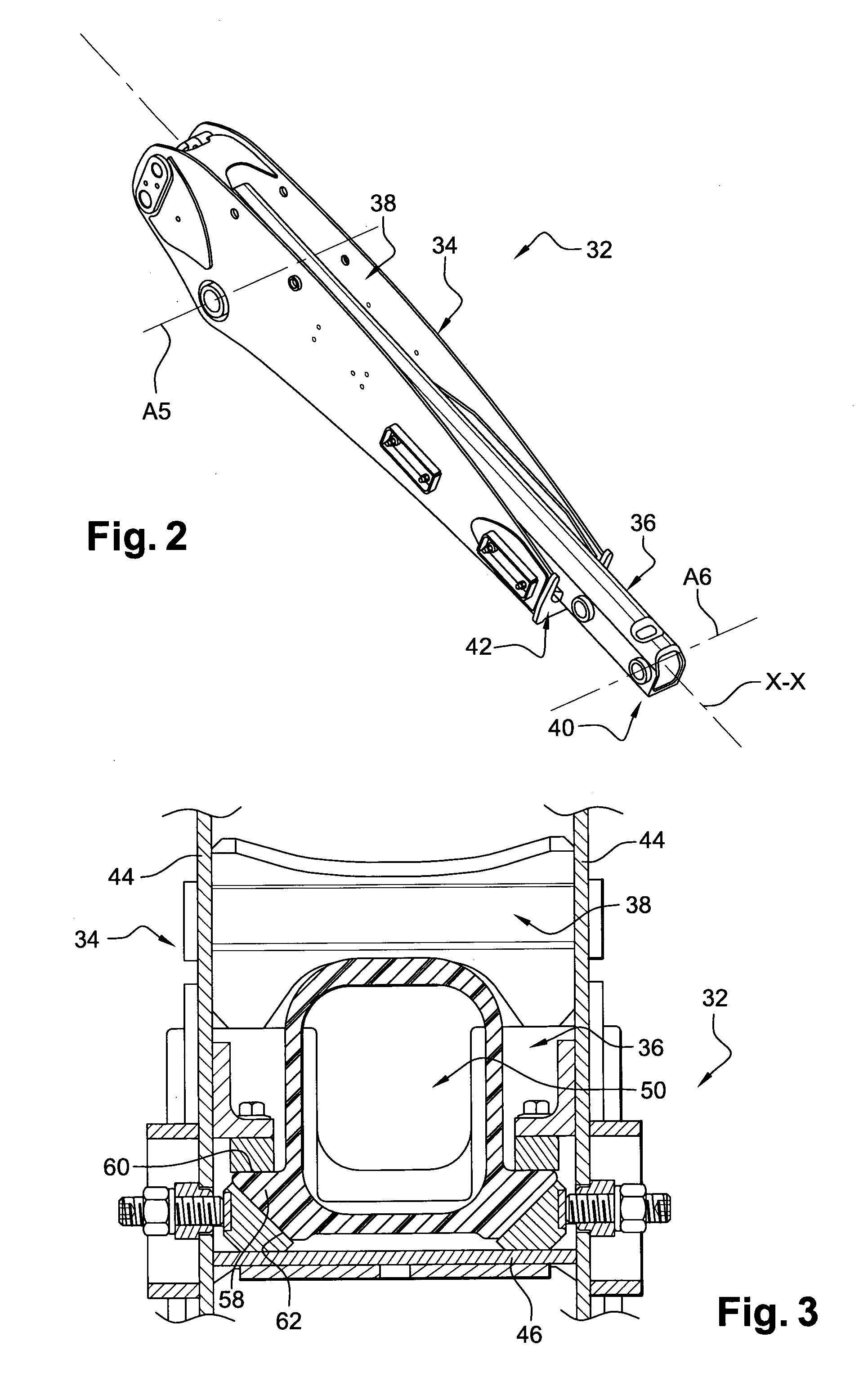

[0014]The backhoe equipment 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com