Palm wrench for 1911 style pistol barrel bushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

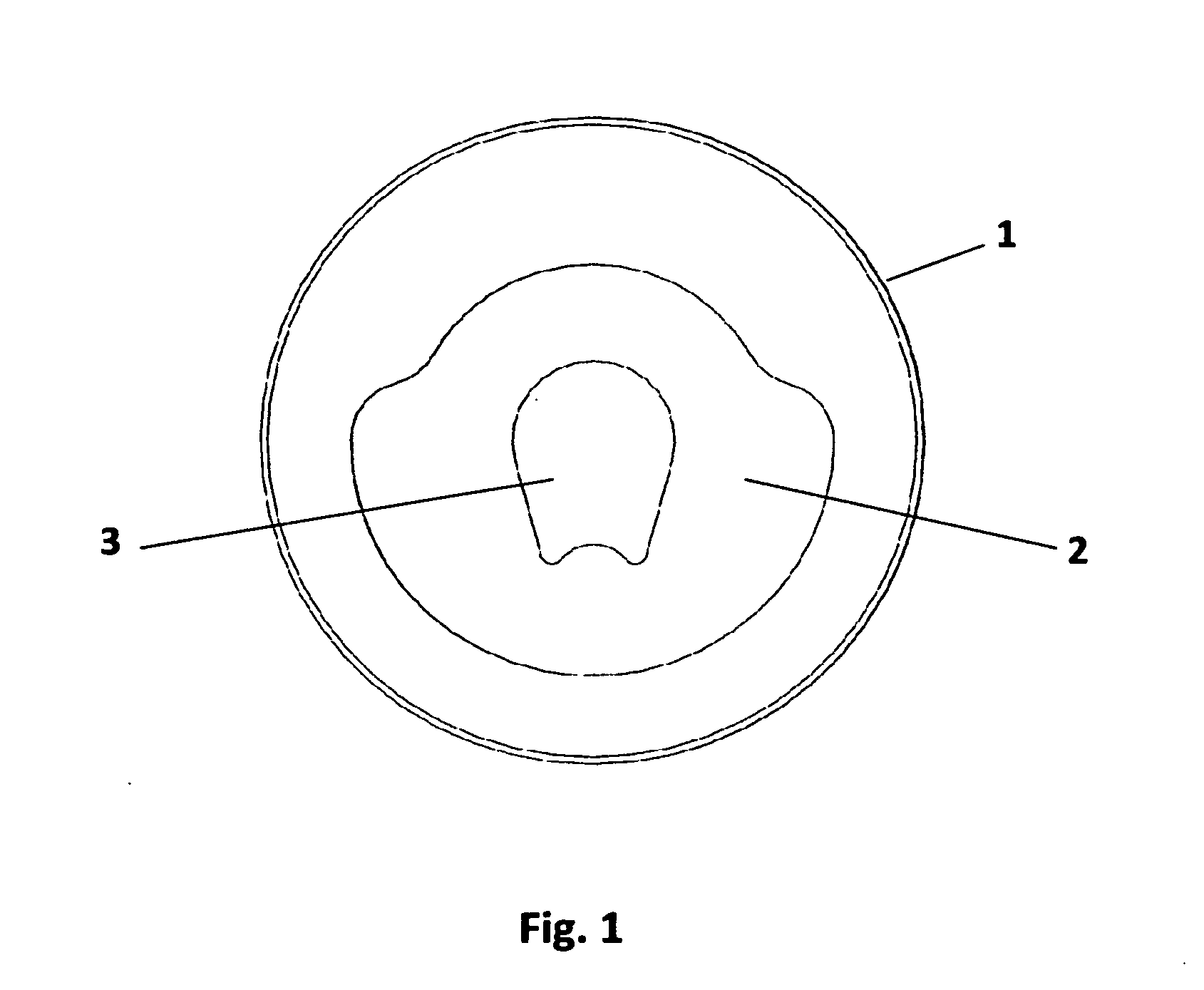

[0027]FIG. 1 shows a rear facing view of the generally annularlar body of the claimed embodiment (1) with recess in tool body. (2) and bushing opening (3). The tool body (1) is preferably comprised of any suitable and durable material, including, but not limited to, metal or plastic. The tool body (1) can be formed through various industrial processes such as investment casting, injection molding, wire electrode discharge machining or laser jet cutting.

[0028]FIG. 2 shows a lateral sectioned view of the claimed embodiment. (1)

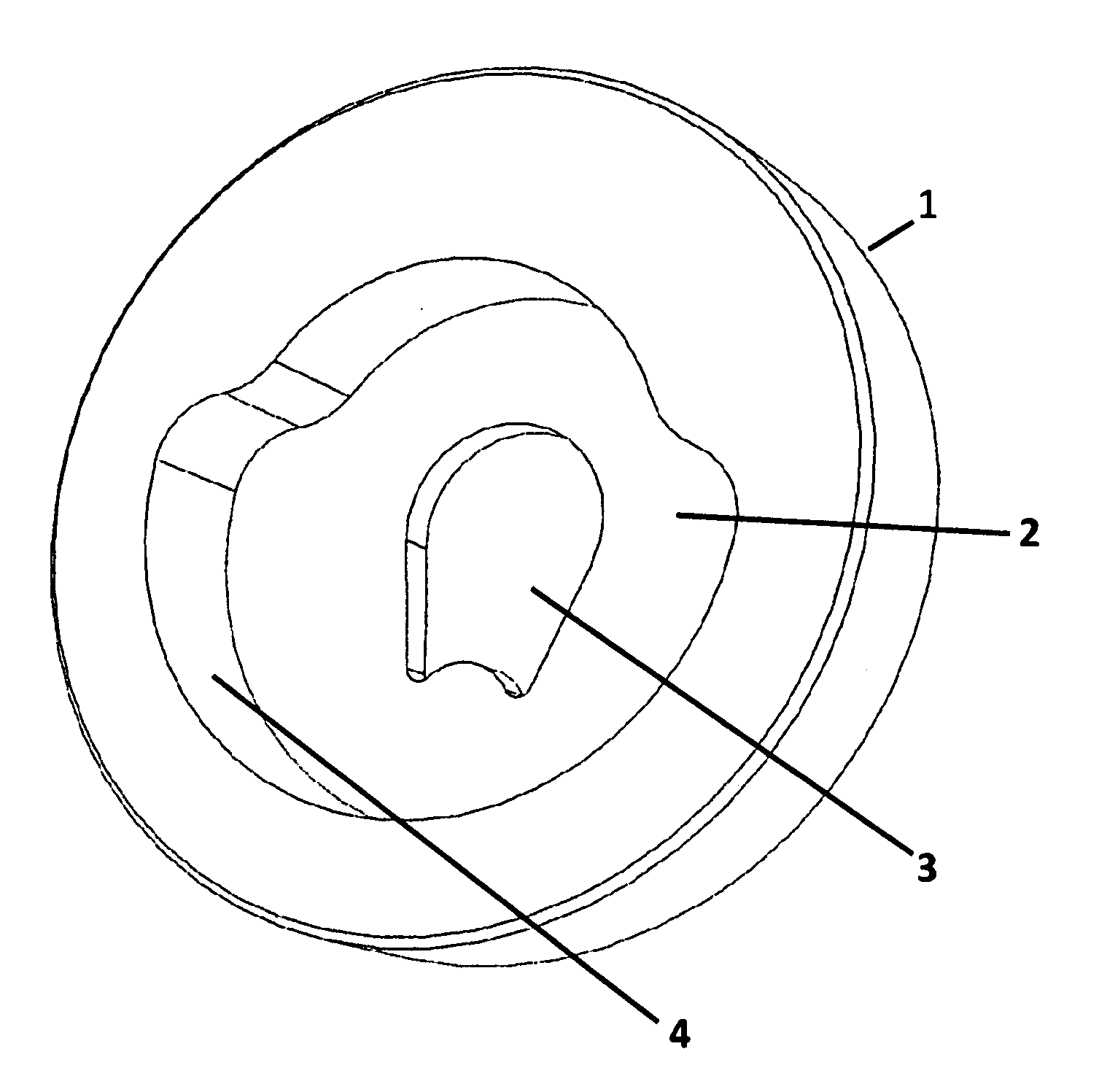

[0029]FIG. 3 shows a perspective sectioned view of the claimed embodiment (1), with recoil spring trapping recess (2), and bushing opening. (3)

[0030]FIG. 4 shows a side view of the end of the pistol slide (7), including the barrel bushing (5) and the spring plug (6).

[0031]FIG. 5 is a side view of the 1911 style pistol (8).

Operation:

[0032]After insuring the pistol (8) has been unloaded, the operator grasps the slide (7) firmly encircling the end of the slide with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com