A permanent magnet flat assembly vehicle

A technology for assembling vehicles and flat plates, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., it can solve problems such as poor contact and dust on the contact surface, and achieve improved static friction coefficient, large control force, and elimination of spot welders. sequential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

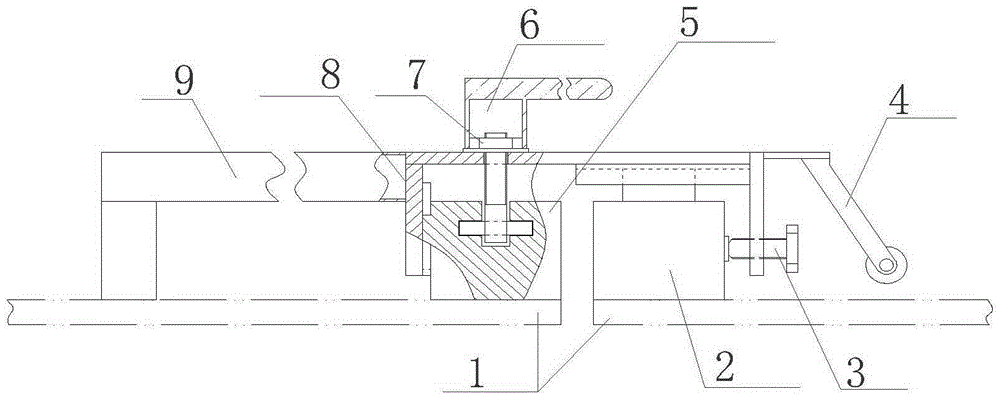

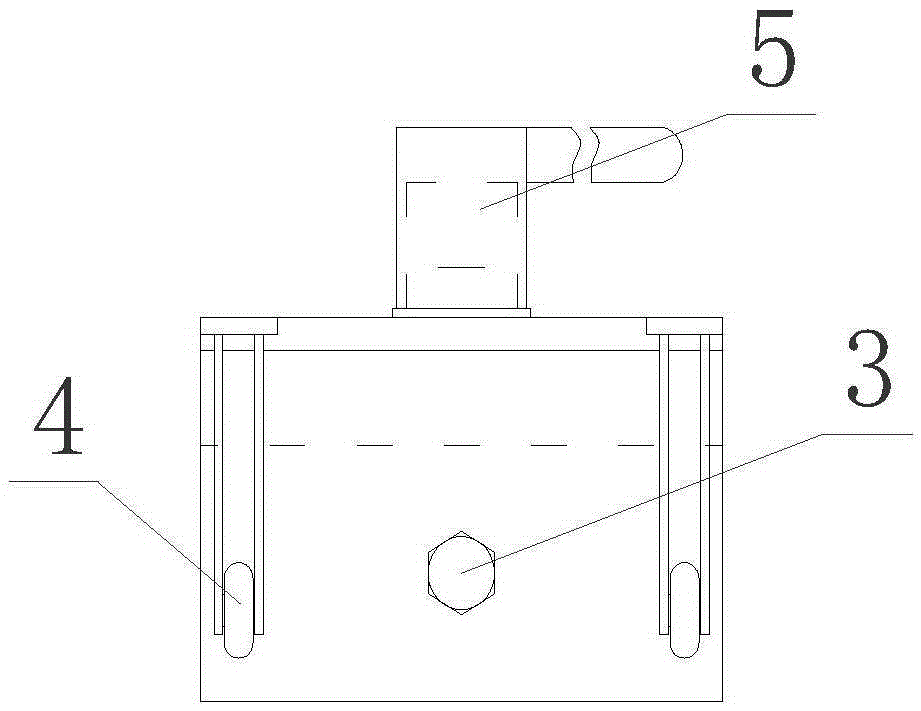

[0023] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

[0024] Those skilled in the art can understand that, unless otherwise defined, all terms (including technical terms and scientific terms) used in the present invention have the same meaning as commonly understood by those of ordinary skill in the art to which the present invention belongs.

[0025] The meanings of "inside and outside" in the present invention refer to that relative to the device itself, the direction pointing to the inside of the device is inward, and vice versa, it is not a specific limitation to the device mechanism of the present invention.

[0026] The meaning of "left and right" mentioned in the present invention means that when the reader is facing the drawings, the left side of the reader is the left, and the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com