Optical scanner apparatus and optical scanner control apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

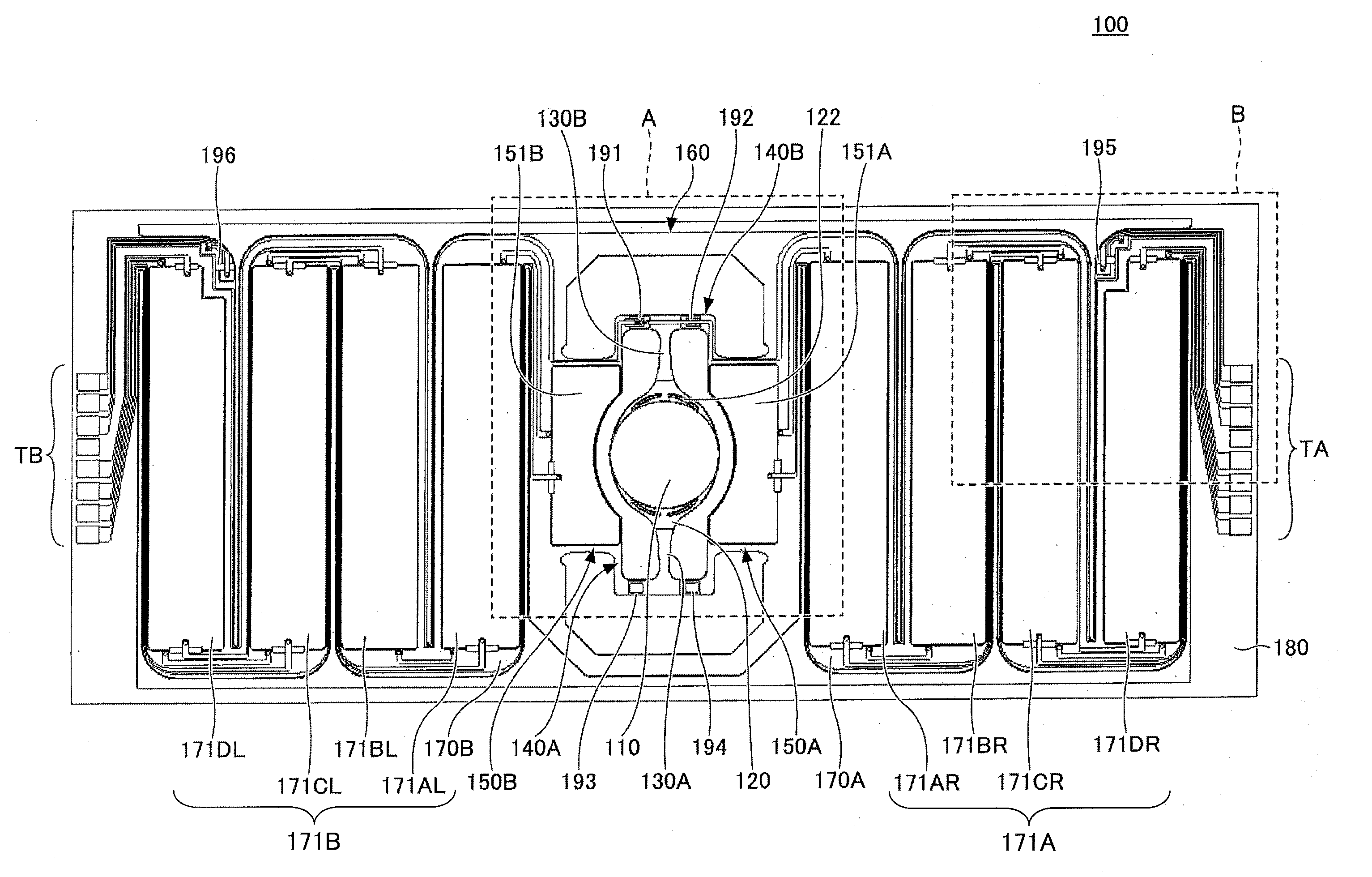

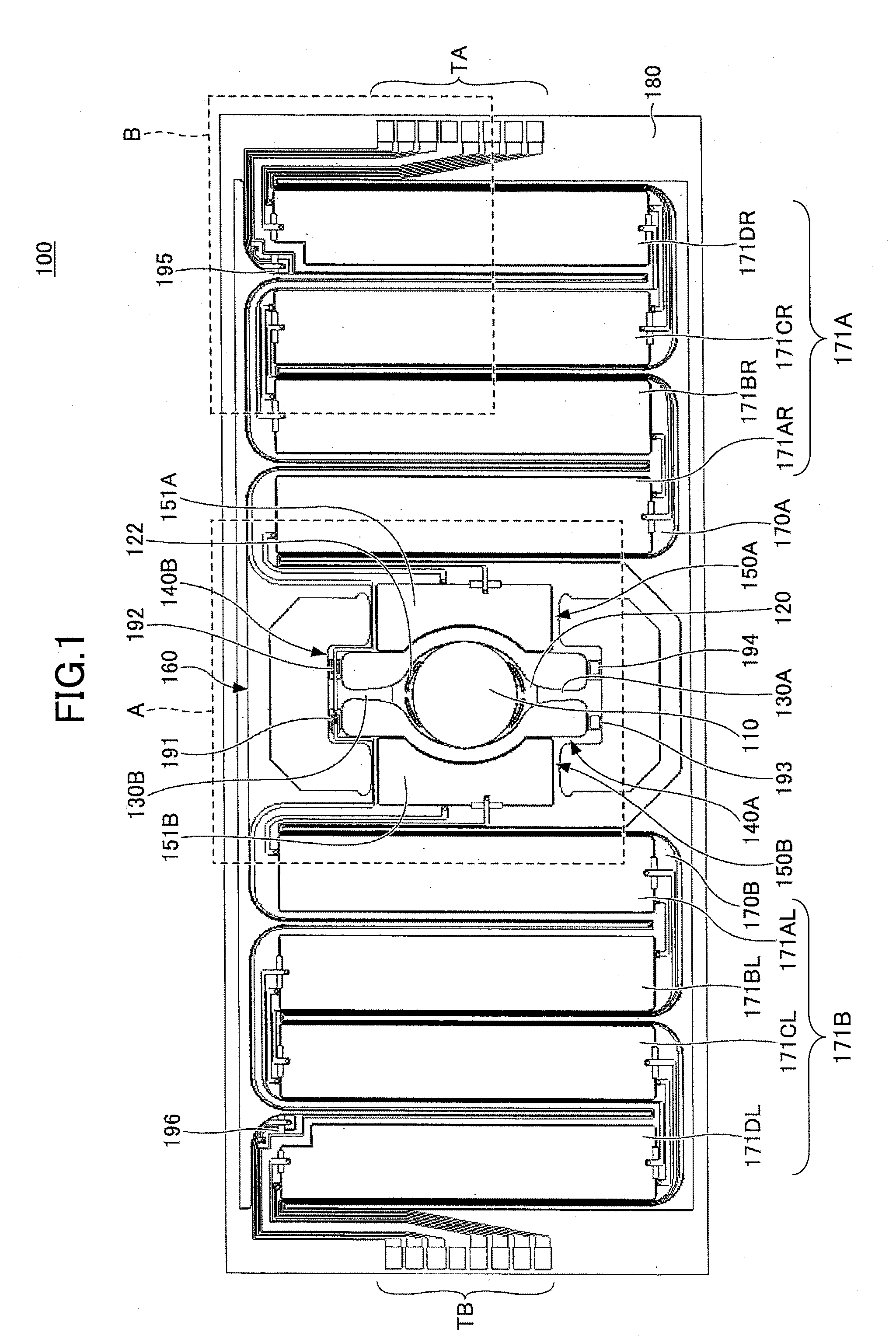

[0048]The first embodiment is explained with reference to drawings. FIG. 1 is a view showing an example of an optical scanner apparatus 100 of the first embodiment.

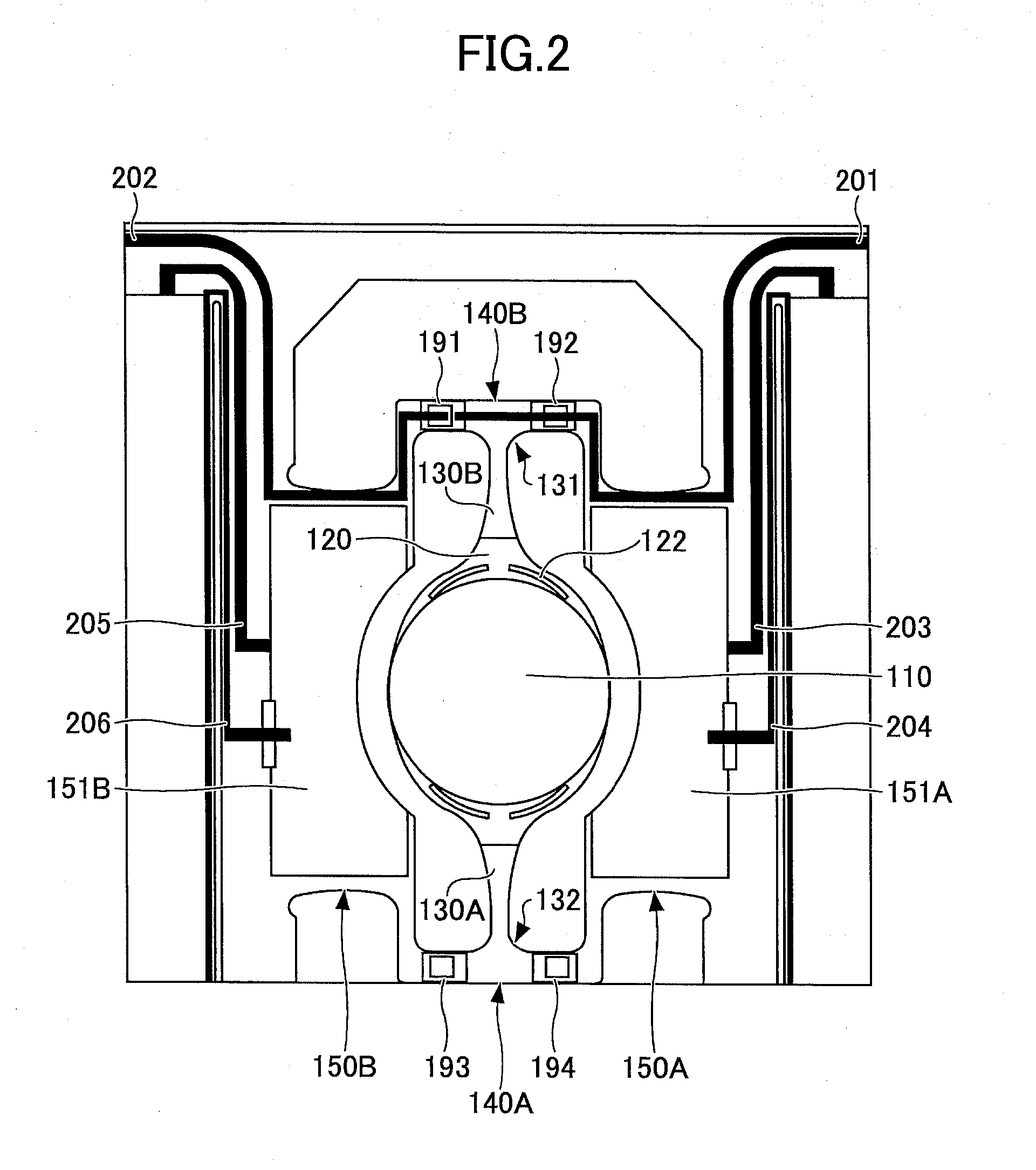

[0049]The optical scanner apparatus 100 of the embodiment includes a mirror 110, a mirror support portion 120, a first torsion beam 130A, a second torsion beam 130B, a first connecting beam 140A, a second connecting beam 140B, a first horizontal driving beam 150A, a second horizontal driving beam 150B, a movable frame 160, a first vertical driving beam 170A, a second vertical driving beam 170B, and a fixed frame 180.

[0050]The first horizontal driving beam 150A and the second horizontal driving beam 150B of the embodiment include a first horizontal driving source 151A and a second horizontal driving source 151B, respectively. The first vertical driving beam 170A and the second vertical driving beam 170B include a first vertical driving source 171A and a second vertical driving source 171B, respectively.

[0051]The mirror sup...

second embodiment

[0092]The second embodiment is explained with reference to drawings. The second embodiment is different from the first embodiment that a guard pattern is provided between the sensor interconnect and the drive interconnect. In the following explanation, the same components are given the same reference numerals, and explanations are not repeated.

[0093]FIG. 4 is a view showing an example of an optical scanner apparatus 100A of the second embodiment. The optical scanner apparatus 100A includes a guard pattern 220 formed between the sensor interconnects (the first sensor interconnect 201) and the drive interconnects (first drive interconnect for lower 203). Further, the optical scanner apparatus 100A includes a guard pattern 221 formed between the second sensor interconnect 202 and the second drive interconnect for lower 205.

[0094]With reference to FIG. 5, the guard patterns 220 and 221 of the embodiment are explained. FIG. 5 is a view showing an example of the guard patterns 220 and 221...

third embodiment

[0107]The third embodiment is explained with reference to drawings. The third embodiment is different from the second embodiment that the guard pattern is only provided from the vicinities of the piezo-electric sensors 195 and 196, respectively. In the following explanation, the same components are given the same reference numerals, and explanations are not repeated. FIG. 8 is a view showing an example of an optical scanner apparatus 100B of the third embodiment. The optical scanner apparatus 100B includes a guard pattern 220A and a guard pattern 221A at the piezo-electric sensor 195 side and the piezo-electric sensor 196 side, respectively.

[0108]FIG. 9 is an enlarged view of a part B2 shown in FIG. 8.

[0109]In this embodiment, the guard pattern 220A which extends along the first sensor interconnect 201 connected to the piezo-electric sensor 191 is formed from a position P3 which is in the vicinity of the piezo-electric sensor 195. The position P3 is almost the same as a starting poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com