Self-feeding steam mop

a steam mop and self-feeding technology, applied in the field of steam mop, can solve the problems of backpressure from the boiler, inconvenient and practical method of feeding steam mop, etc., and achieve the effect of convenient and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

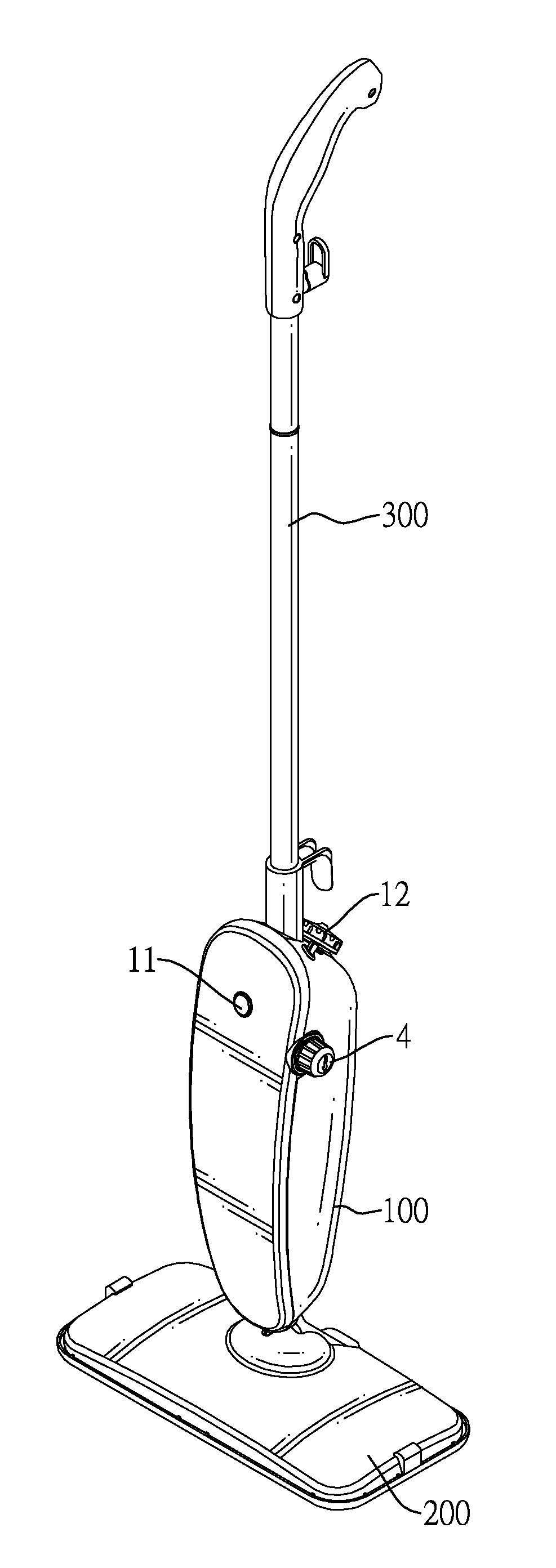

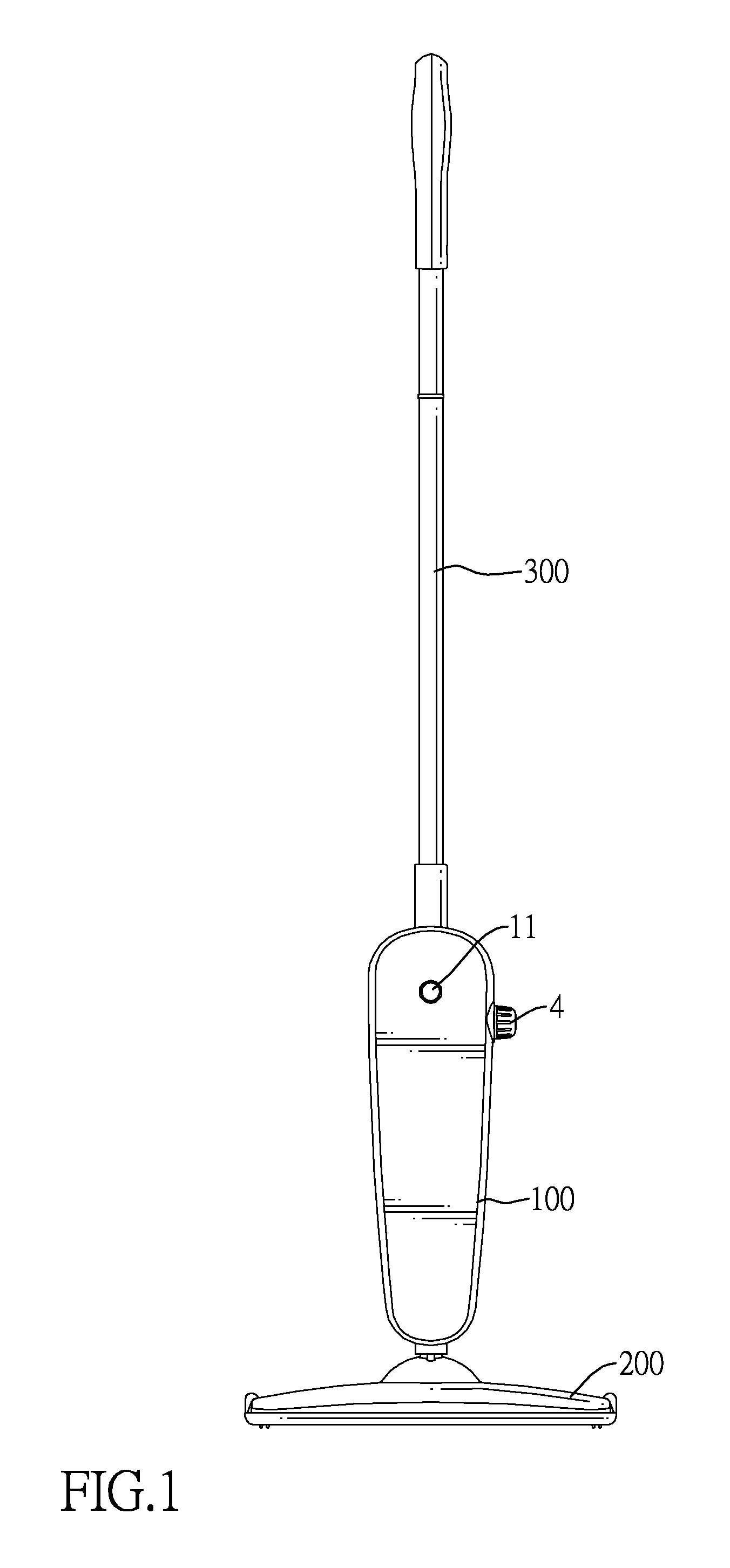

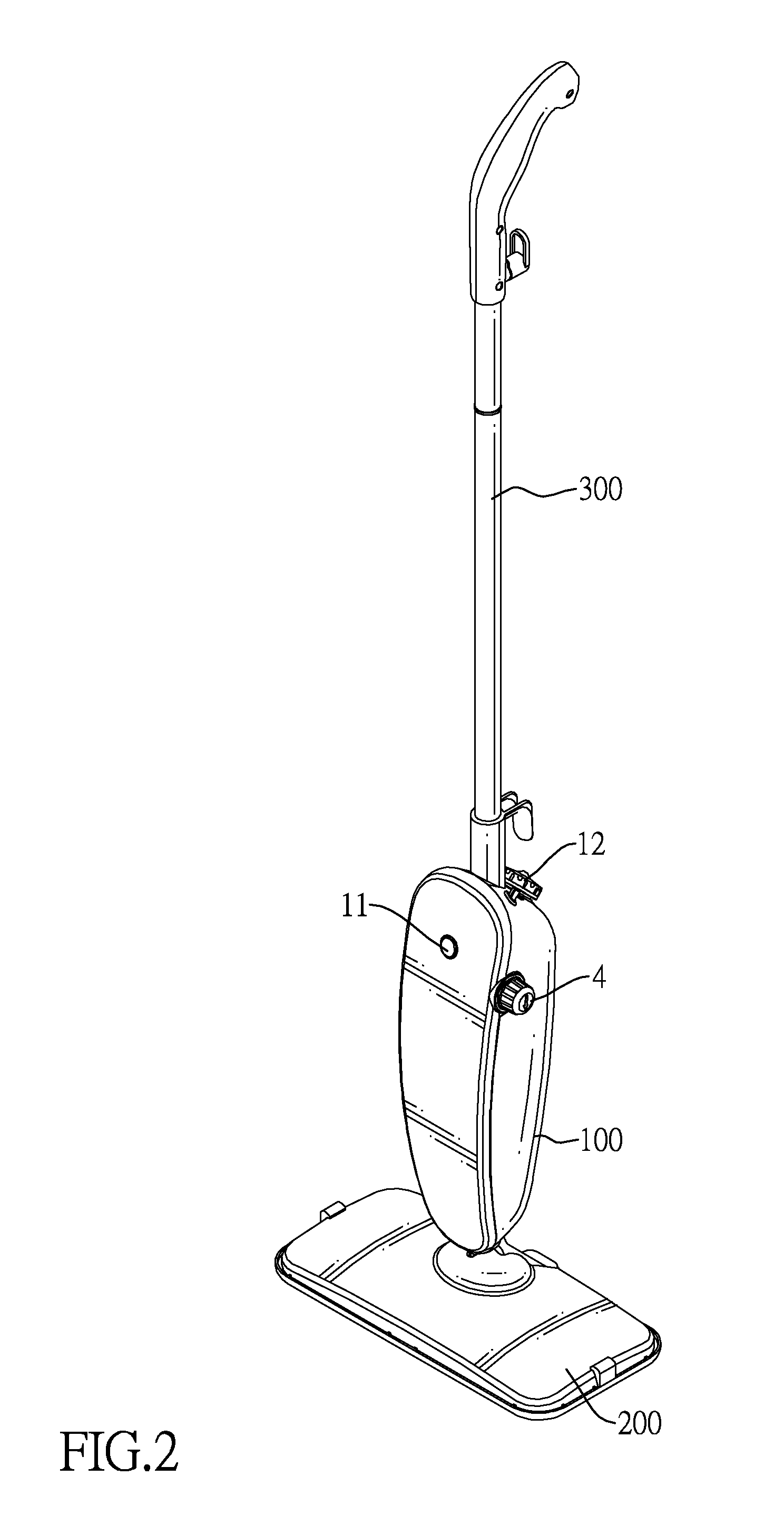

[0020]With reference to FIG. 1 to FIG. 3, a self-feeding steam mop in accordance with the present invention is lightweight, inexpensive and highly efficient in housework.

[0021]The self-feeding steam mop comprises a handle 300, a steam assembly 100 and a mop head 200. All of the handle 300, steam assembly 100 and mop head 200 can be varied in size and shape and color for difference requirements.

[0022]With reference to FIGS. 3, 4A and 4B, the steam assembly 100 is mounted under the handle 300 and has a casing 101, a light 11, a water cap 12, a control mechanism, a water control valve 6, a check valve 7 and a boiler 8.

[0023]The casing 101 is hollow and has a water tank 1 and a vent valve 2.

[0024]The water tank 1 is mounted on a top of the casing 101 of the steam assembly 100 and has a water inlet and a water outlet. The water tank 1 provides a higher (positive) pressure (water weight plus 1 atm) than that inside the boiler 8 so that the water in the water tank 1 feeds into the boiler 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com