Thermal energy storage system

a technology of energy storage and thermal energy, which is applied in the direction of steam accumulators, machines/engines, steam engine plants, etc., can solve the problems of large-scale energy storage systems that are often mismatched, and tend to be cost prohibitive, so as to facilitate sub-atmospheric flashing and facilitate the storage and retrieval of electrical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

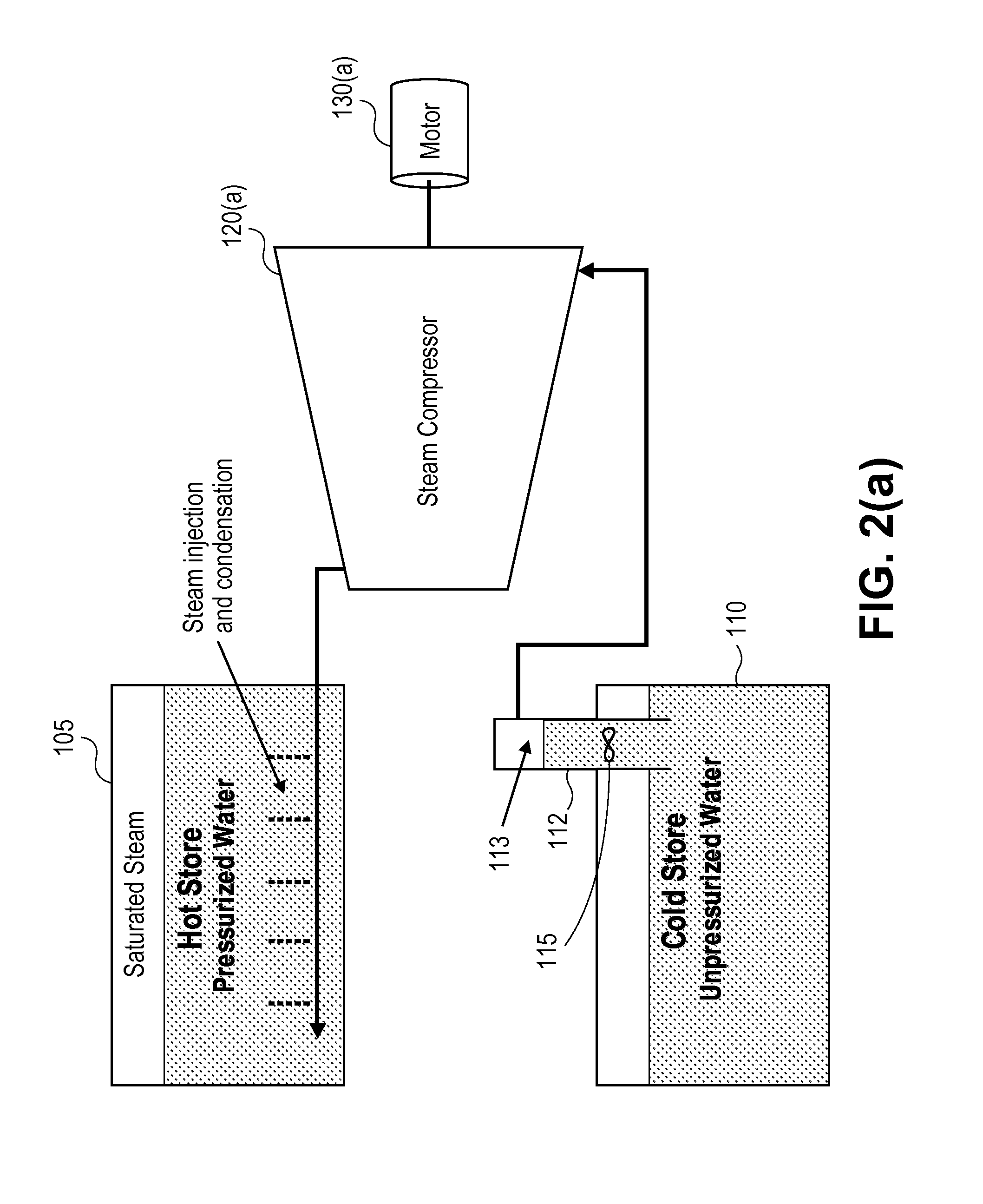

[0020]A number of thermal energy based energy storage and retrieval systems are described. In general, the described storage systems utilize a working fluid having a substantial heat capacity and make use of a phase change to help improve the storage capacity of the system (e.g. a liquid water / steam phase change).

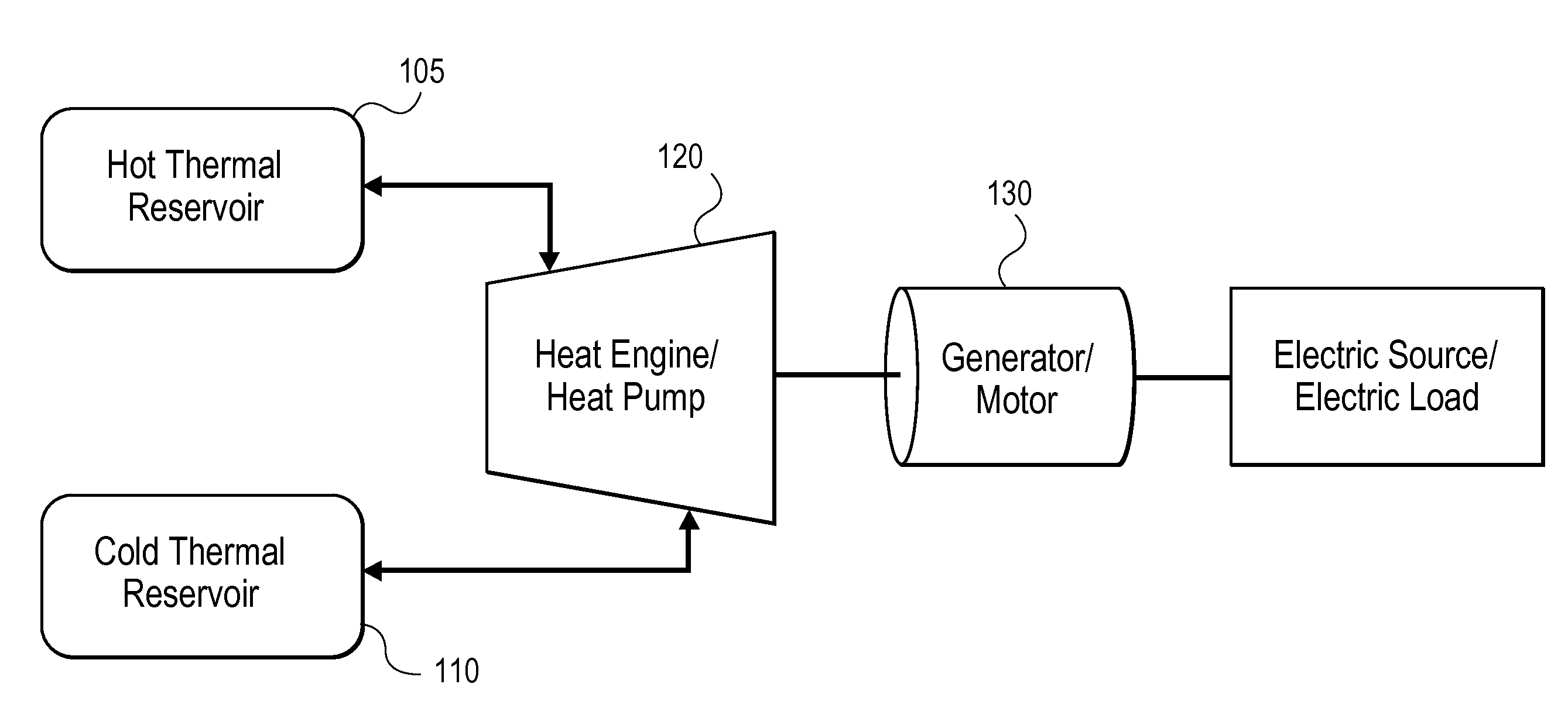

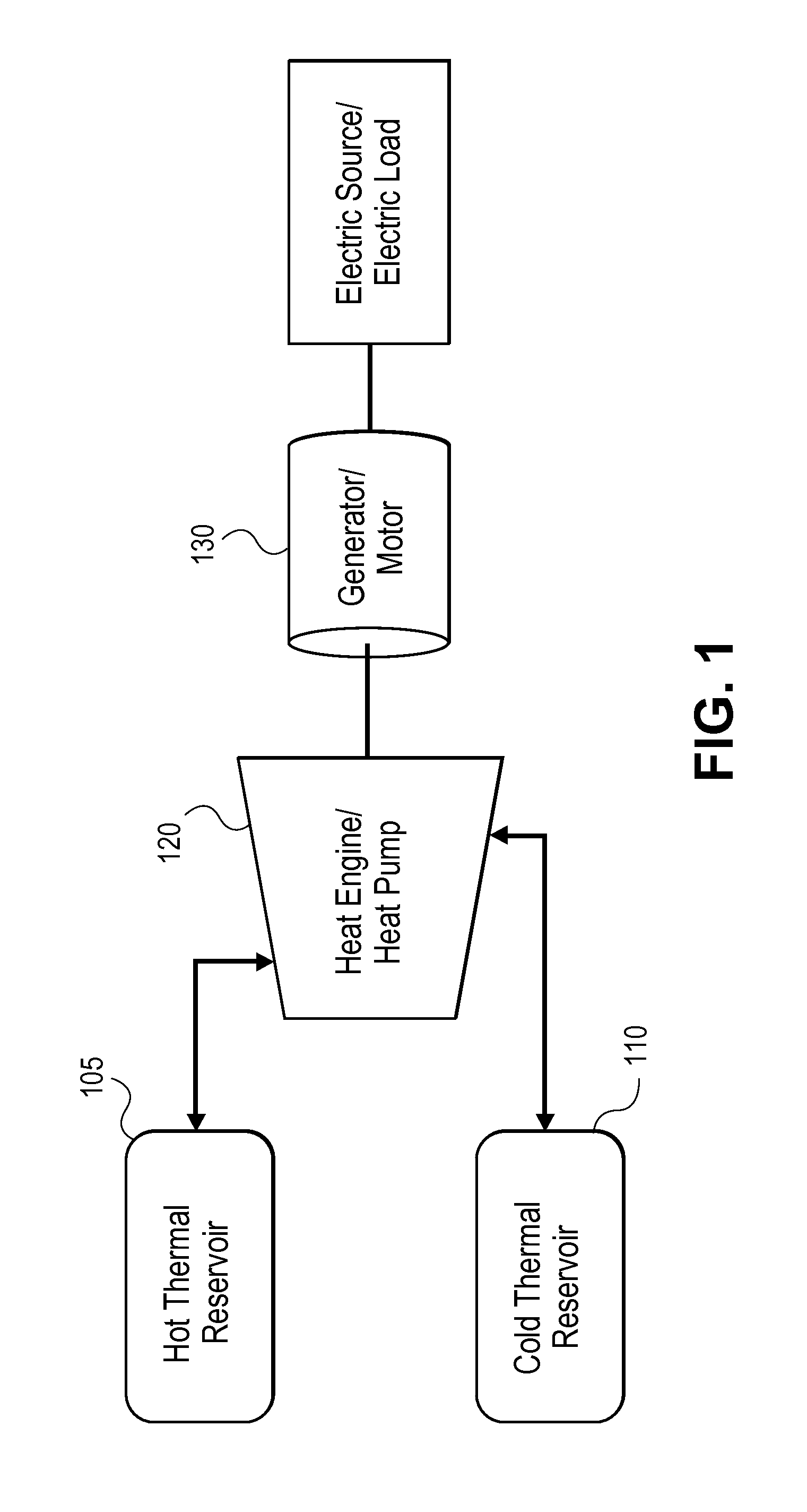

[0021]Referring next to FIG. 1, a basic architecture of a heat engine / heat pump based electrical energy storage and retrieval in accordance with one embodiment of the invention will be described. The storage system 100 includes a “hot” thermal reservoir 105 and a “cold” thermal reservoir 110. A heat engine / heat pump 120 is used to convey a working fluid between the two thermal reservoirs 105 and 110. In the illustrated embodiment, the heat engine / heat pump 120 is coupled to a generator / motor 130 which in turn is coupled to an electric source and the electric load as appropriate. When operating the system 100 in a manner that stores energy, electricity from an electrical sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com