Shiplap joint

a technology of shiplap and joint, applied in the field of building panels, can solve the problems of requiring additional labor during application and eventual replacement, and gaps in coverage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

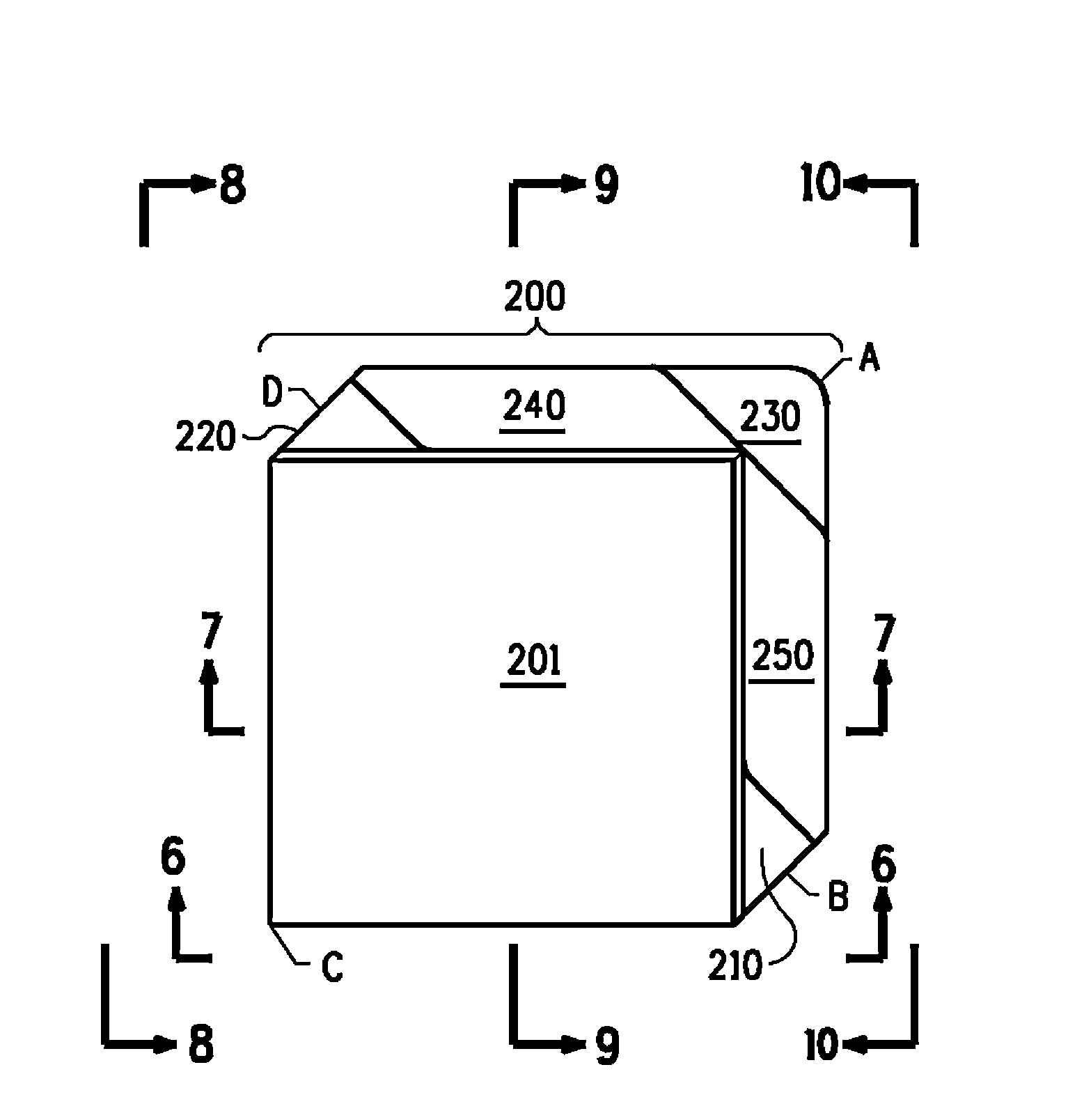

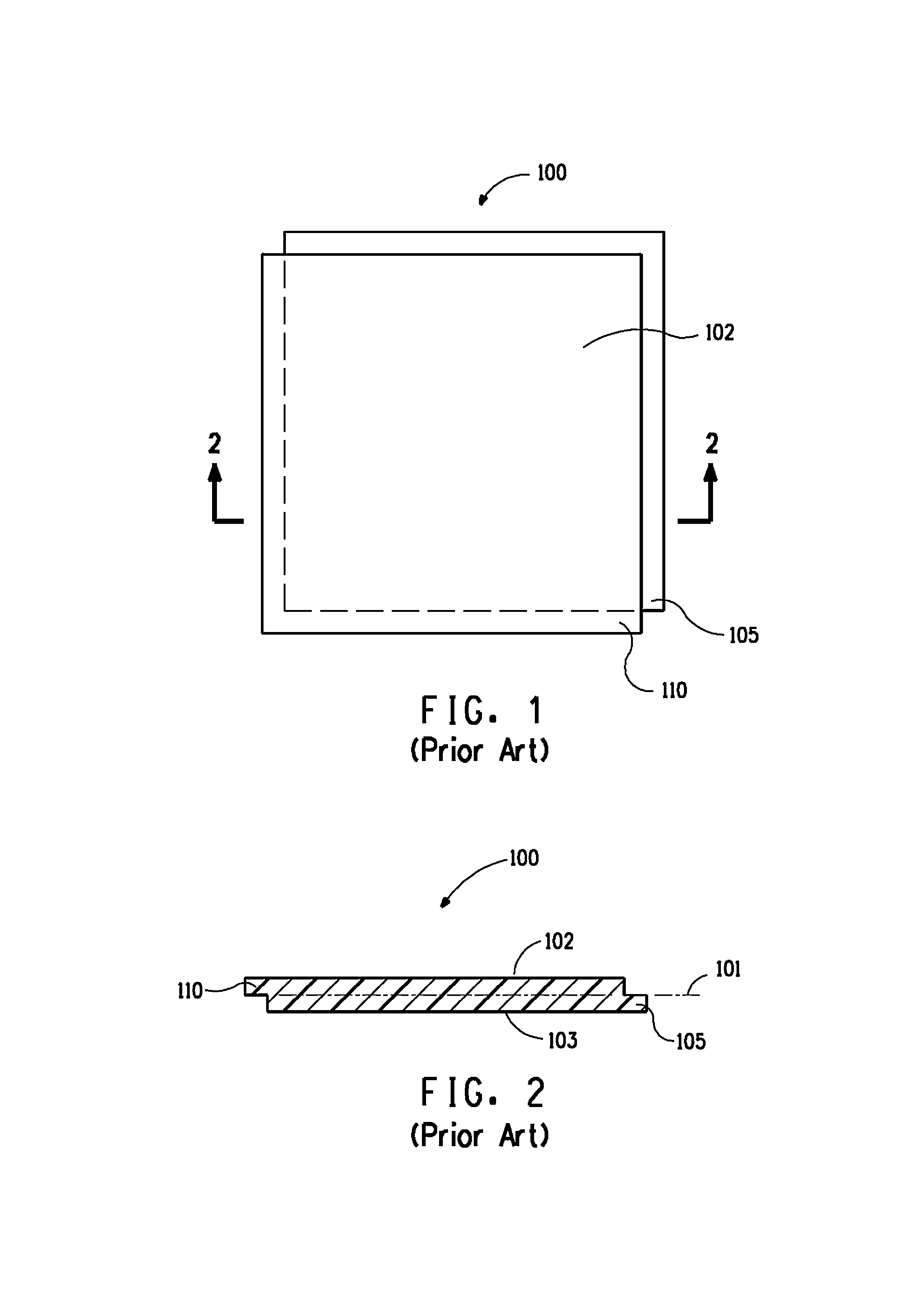

[0038]The subject invention is a building panel with an improved shiplap joint that eliminates the coverage gaps at the corner intersection of building panels. The building panel includes a first face known as a frontface (201) which is exposed to view after installation on the building, which includes an overlap (210-350) portion adapted to overlay the underlap (210-250) of a second face known as backface (301) of one or more improved shiplap building panels laid up in the next higher course of a building wall surface. Prior art shiplap joints use an overlay (110) and underlay (105) that typically mate along the plane of a centerline (101) of the panel. The improved shiplap joint uses backcenterlaps (210, 220) and frontcenterlaps (310, 320) formed along a third plane, or thickness, of material at a center plane of building panels which straddle the plane of the centerline (204). Each pair of backcenterlaps (210, 220) and frontcenterlaps (310, 320) are located at diagonally opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com