Wind Turbine Tower

a technology of wind turbines and towers, applied in the direction of building components, building repairs, foundation engineering, etc., can solve the problems of large base of wind turbines and may exceed the normal carrying limits of flatbed trucks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

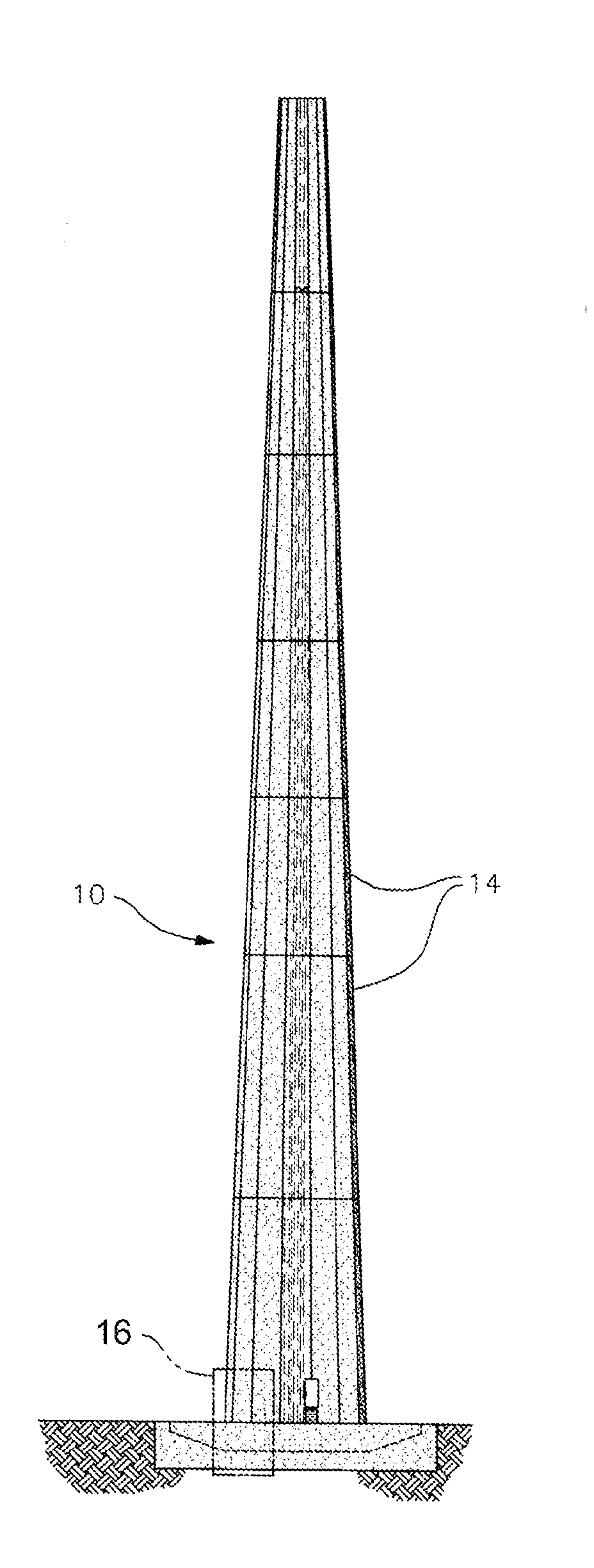

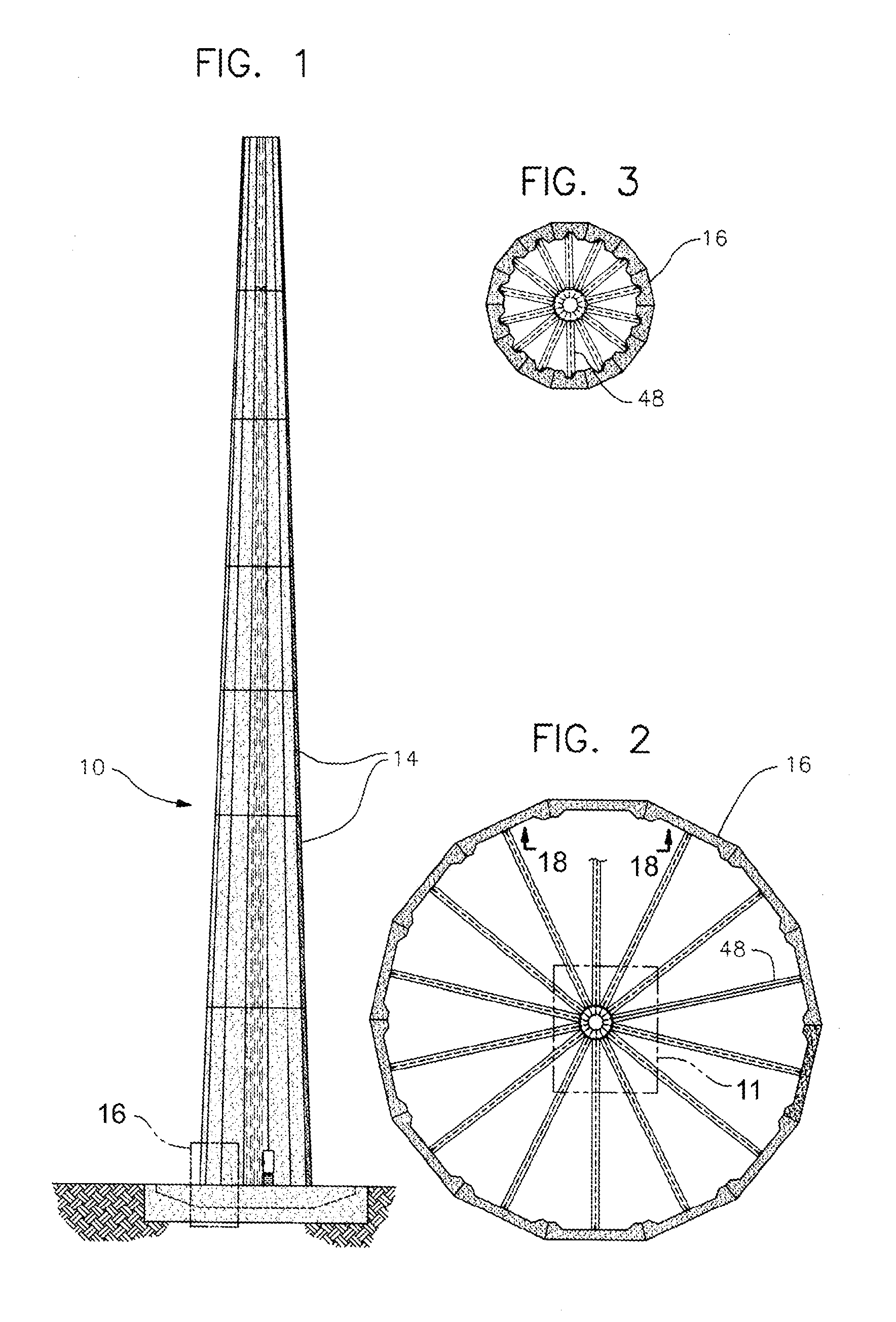

[0031]A wind tower 10 is erected on a foundation 12 using multiple levels 14, with each level 14 having a plurality, shown as fourteen, of panels 16 that are separately cast and brought on site for erection. The foundation 12 is typically of concrete, and previous foundations have been huge, often six to twelve feet thick and up to sixty feet square or in diameter. Existing foundations may be used with this invention. As shown in FIGS. 1 and 17, the first level 14 of concrete panels 16 must be secured to the foundation 12. As shown, one suitable method is to use an anchor bolt system such as from Williams Form Engineering Corporation which employs long threaded anchor bolts 20 embedded in the concrete foundation 12. Any suitable anchor method may be used to anchor the first level of panels 16 to a foundation 12.

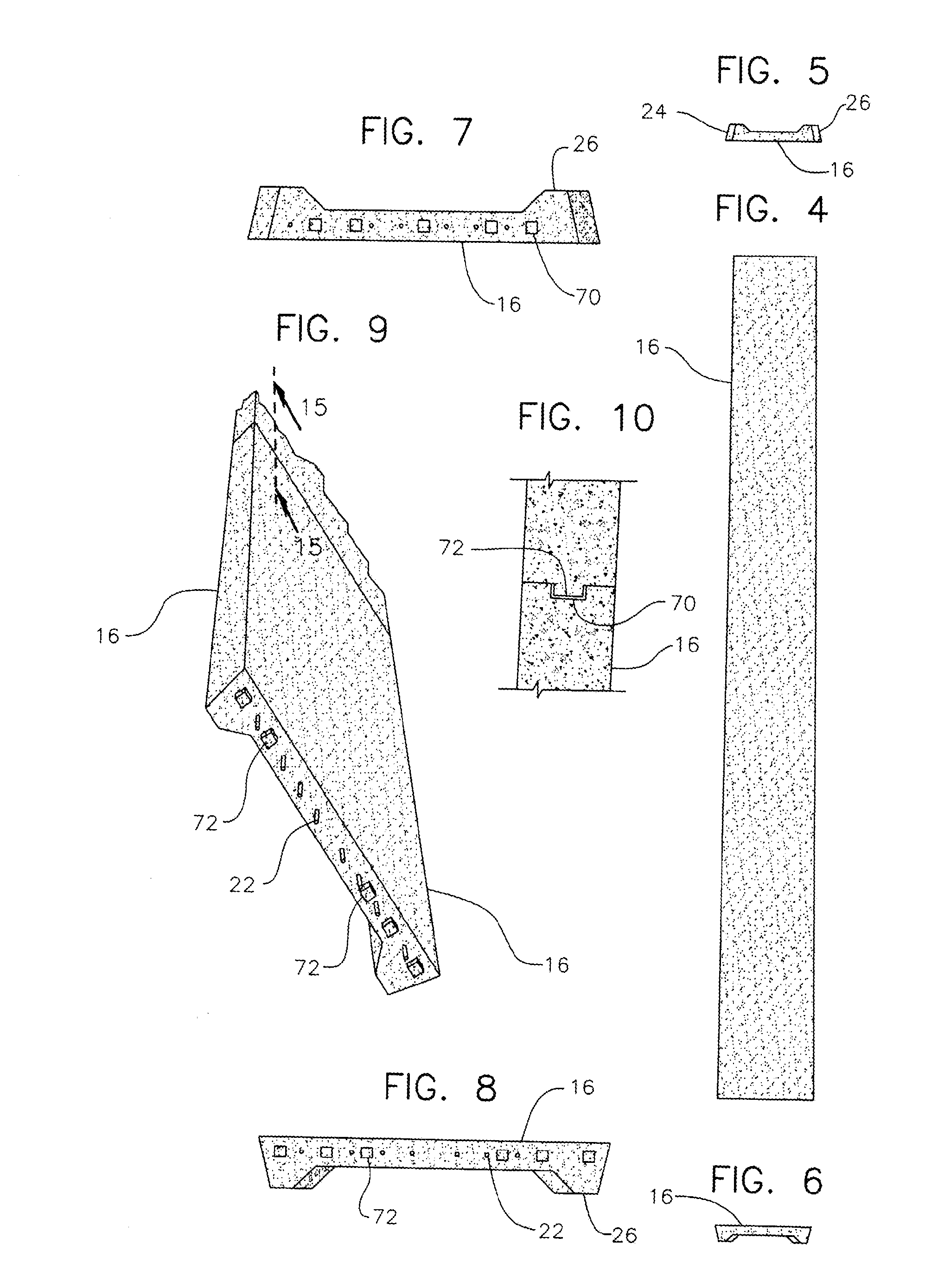

[0032]The first level of panels 16 are arranged on the foundation 12 to affix to anchor bolts 20 in the foundation. Each panel 16, as shown in FIGS. 4-10, is a cast concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com