Chair or couch with motor-driven movable parts

a motor-driven, chair technology, applied in the field of adjustable seating furniture, can solve the problems of affecting the overall installation, and requiring a long time to complete, so as to facilitate the overall installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

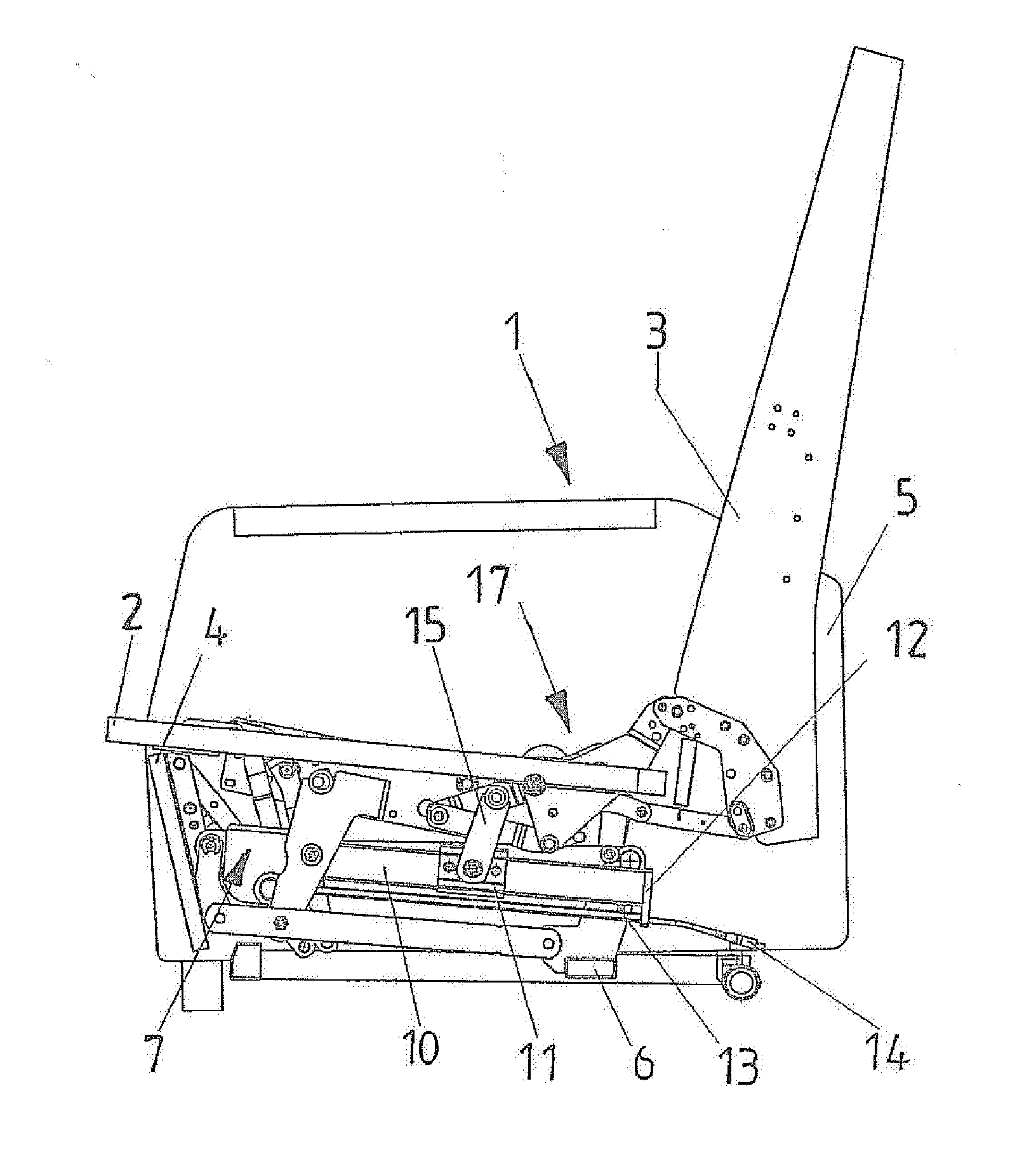

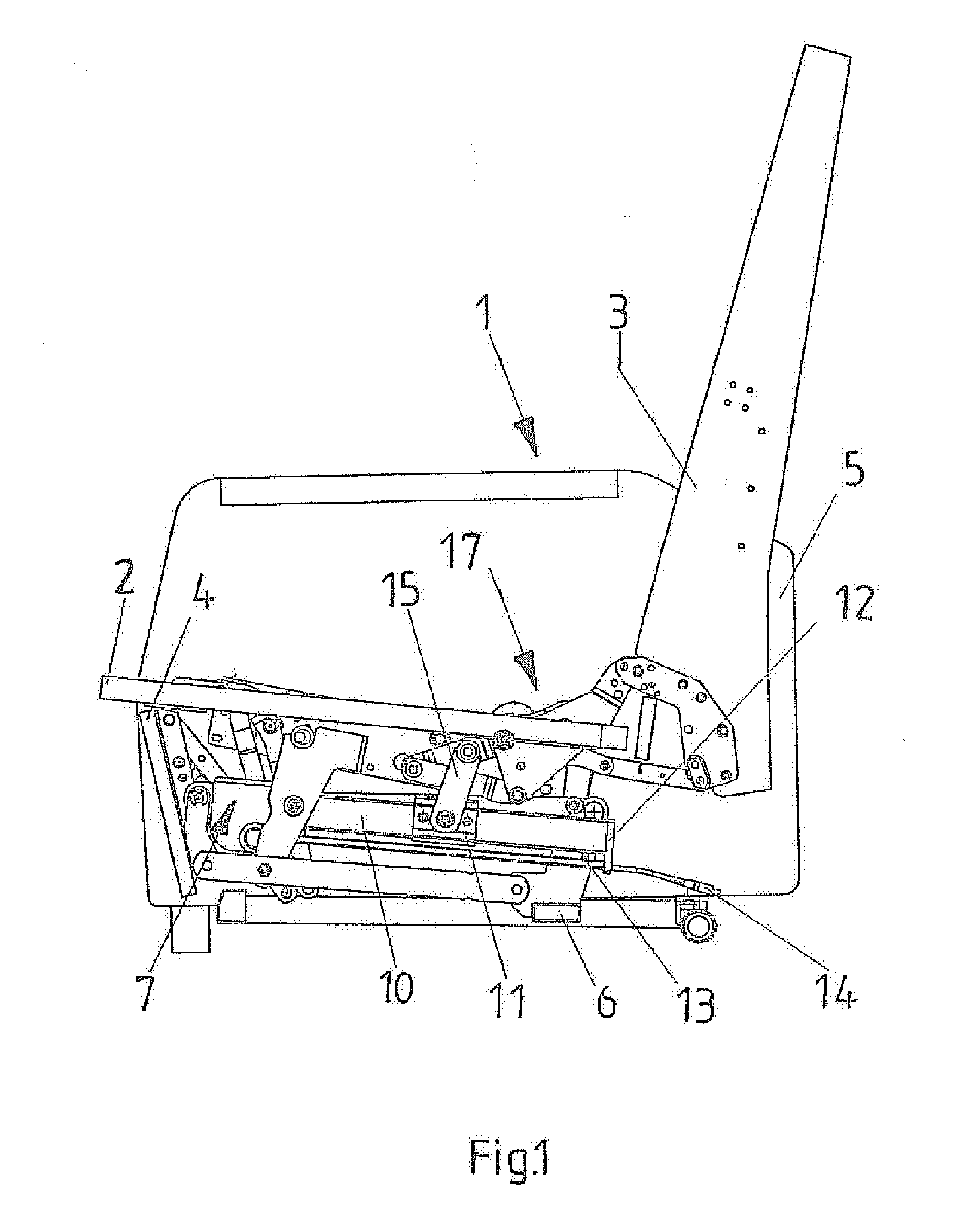

[0022]As seen in FIG. 1 a couch or chair 1 has a generally horizontal seat 2, an upright back 3 projecting up from a rear end of the seat 2, and a footrest 4 projecting down from a front end of the seat 2, all shown without upholstery or cushions for clarity of view. These parts 2, 3, and 4 are all slidable and / or pivotal on a frame 5 having a longitudinal floor beam 6 by a linkage 17.

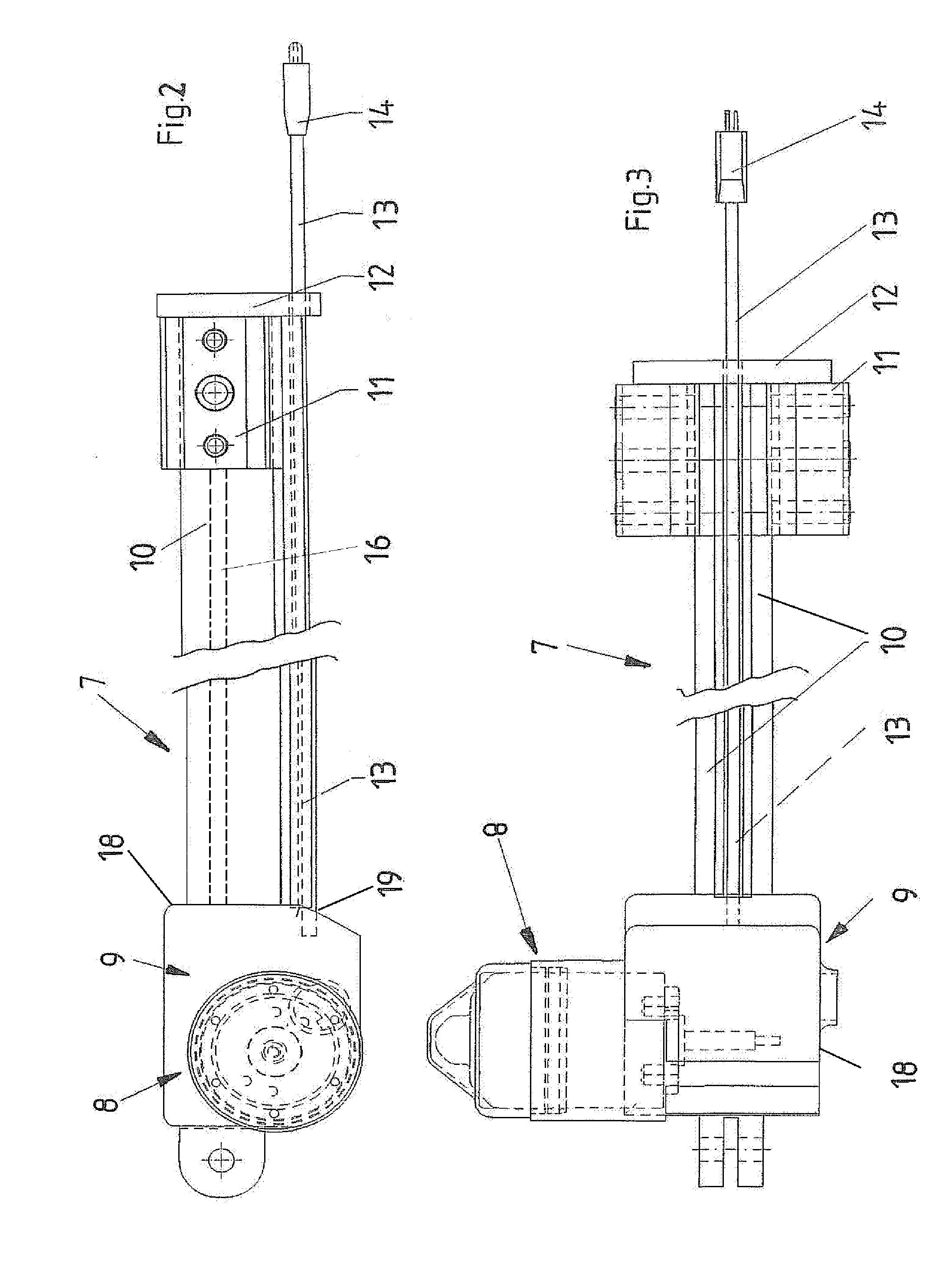

[0023]In addition, an electric-motor-driven drive 7 is attached, for example, to the beam 6 and serves for operating the linkage 17. It has an electric drive motor 8 with a step-down transmission 9. A tube 10 extends from a housing 18 surrounding the motor 8 and transmission 9 and coaxially receives a drive element, such as, for example, a threaded spindle 16 that is operatively connected to the step-down transmission 9.

[0024]An adjustment slide 11 can move along the outer surface of the tube 10, with its longitudinal front-to-back position determined by the drive element 16, so that it connects this d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com