Molded ready-to-tile shower bases with associated trenches and drains

a technology of shower pans and trenches, which is applied in the field of ready-to-tile molded leak-proof shower pans, can solve the problems of high cost of arrangements, inconvenient installation of shower pans, and no ready-to-tile partially prefabricated shower pans on the market today

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

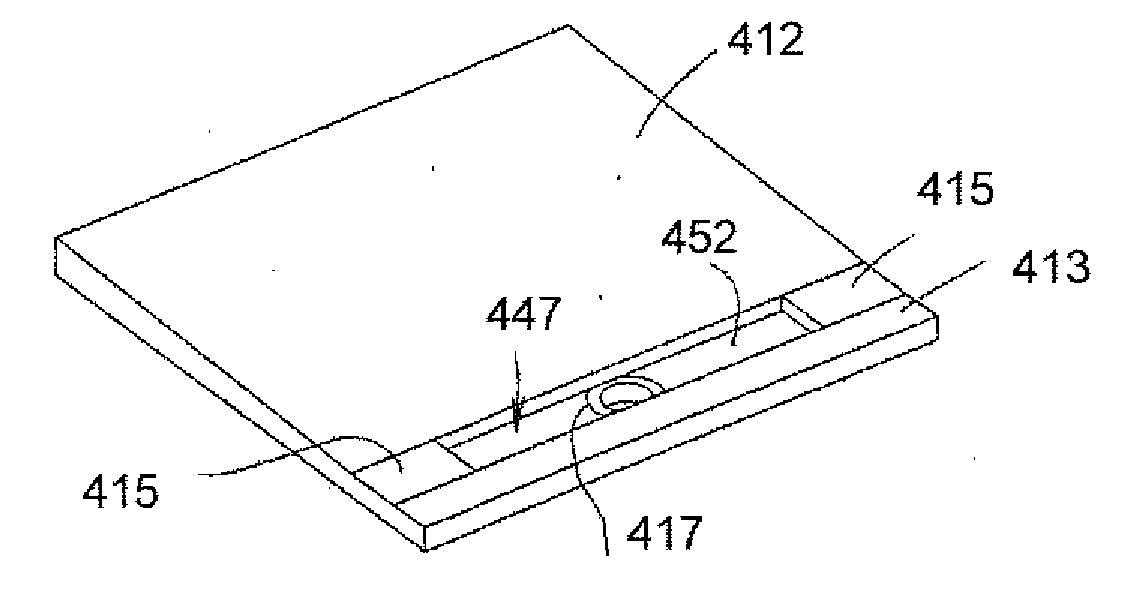

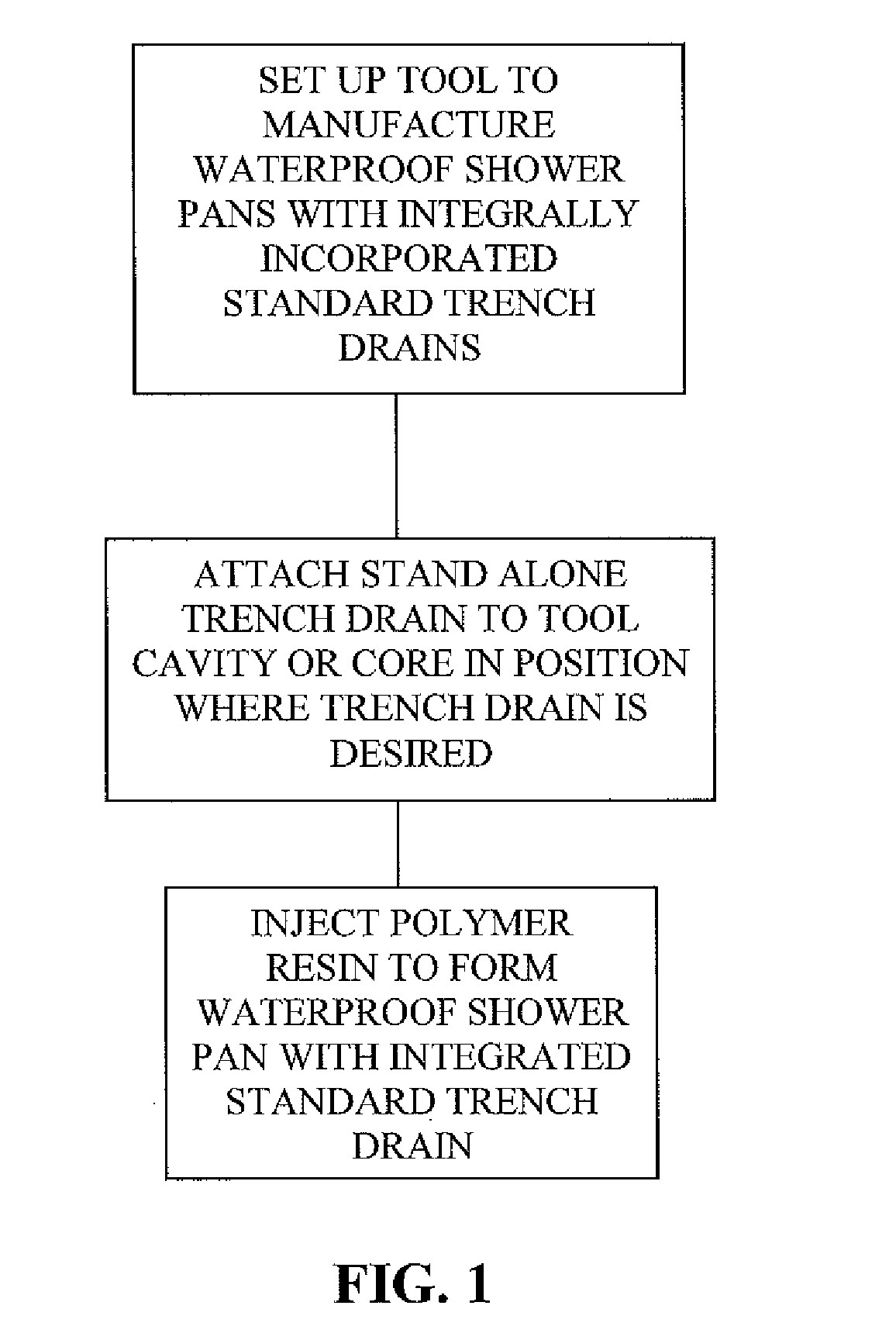

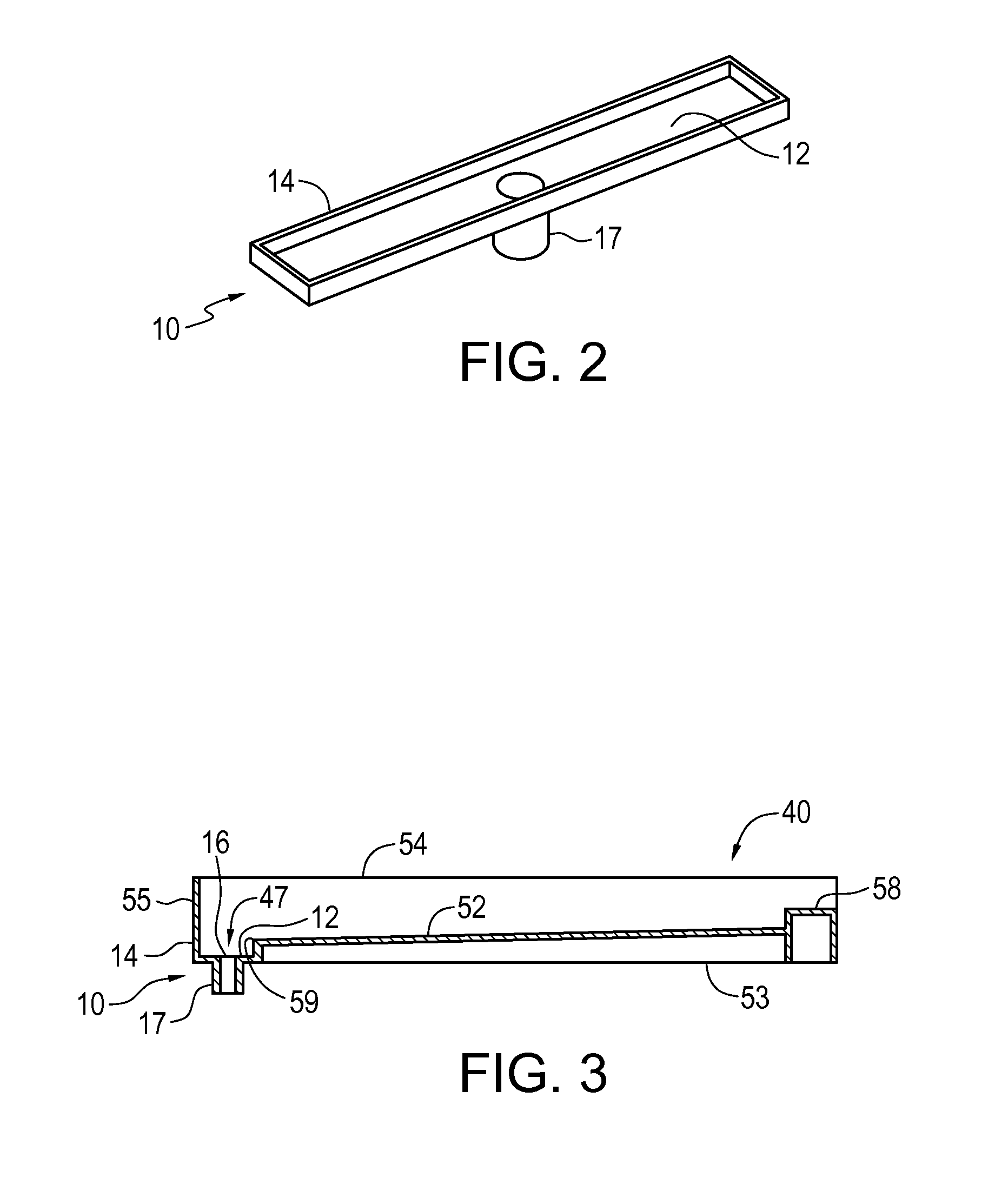

[0079]Before describing in detail exemplary embodiments pertaining to the present invention, it should be observed that the inventive embodiments of my invention reside primarily in combinations of structural components and manufacturing, installation and use steps related to the creation, implementation, installation and use of trench drains or trench bodies with a standard drain in showers and other apparatus where liquid drainage is required.

[0080]Accordingly, the apparatus components have been represented where appropriate by conventional symbols in the drawings, showing only those specific details that are pertinent to understanding the embodiments of the present invention so as not to obscure the disclosure with details that will be readily apparent to those of ordinary skill in the art having the benefit of the description herein.

[0081]In this document, relational terms, such as “first” and “second,”“top” and “bottom,” and the like, may be used solely to distinguish one enti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com