Fluorination of Fluoropolymer Resin to Reduce Discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

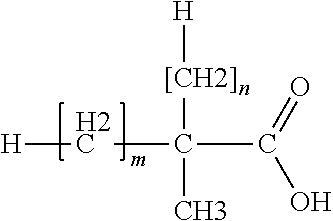

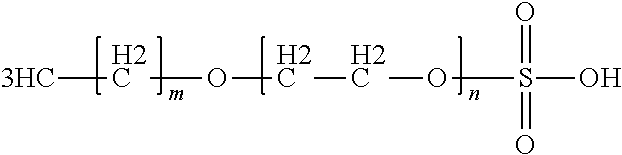

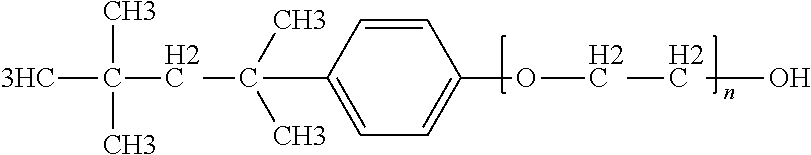

Image

Examples

example 1

Exposing Fluoropolymer Resin to Fluorine

[0093]Aqueous FEP dispersion polymerized as described above is coagulated in a heated glass reactor. 1250 ml of dispersion is heated to 85° C. in a water bath and then transferred to a 2,000 ml jacketed glass reactor with four internal baffles produced by Lab Glass or Vineland, N.J. where the temperature is maintained at by circulating 85° C. water through the jacket. Two high-shear impellers are turned at 2,470 rpm for 3600 seconds to cause the dispersion to separate into a polymer phase and a water phase. The water is separated from the solids by filtering through a 150 micron mesh filter bag model NMO150P1SHS manufactured by The Strainrite Companies of Auburn, Me. The polymer phase is dried for 40 hours in a circulating air oven set at 150° C. to produce a dry powder.

[0094]A sample of dried powder is molded to produce color films as described in the Test Methods section above as Measurement of Thermally Induced Discoloration for melt-proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com