Display-Based Control for Motor Grader

a display-based control and motor grader technology, applied in mechanical machines/dredgers, analogue processes for specific applications, instruments, etc., can solve problems such as blade-obstacle collisions, incomplete grading, and complex tasks of motor grader users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

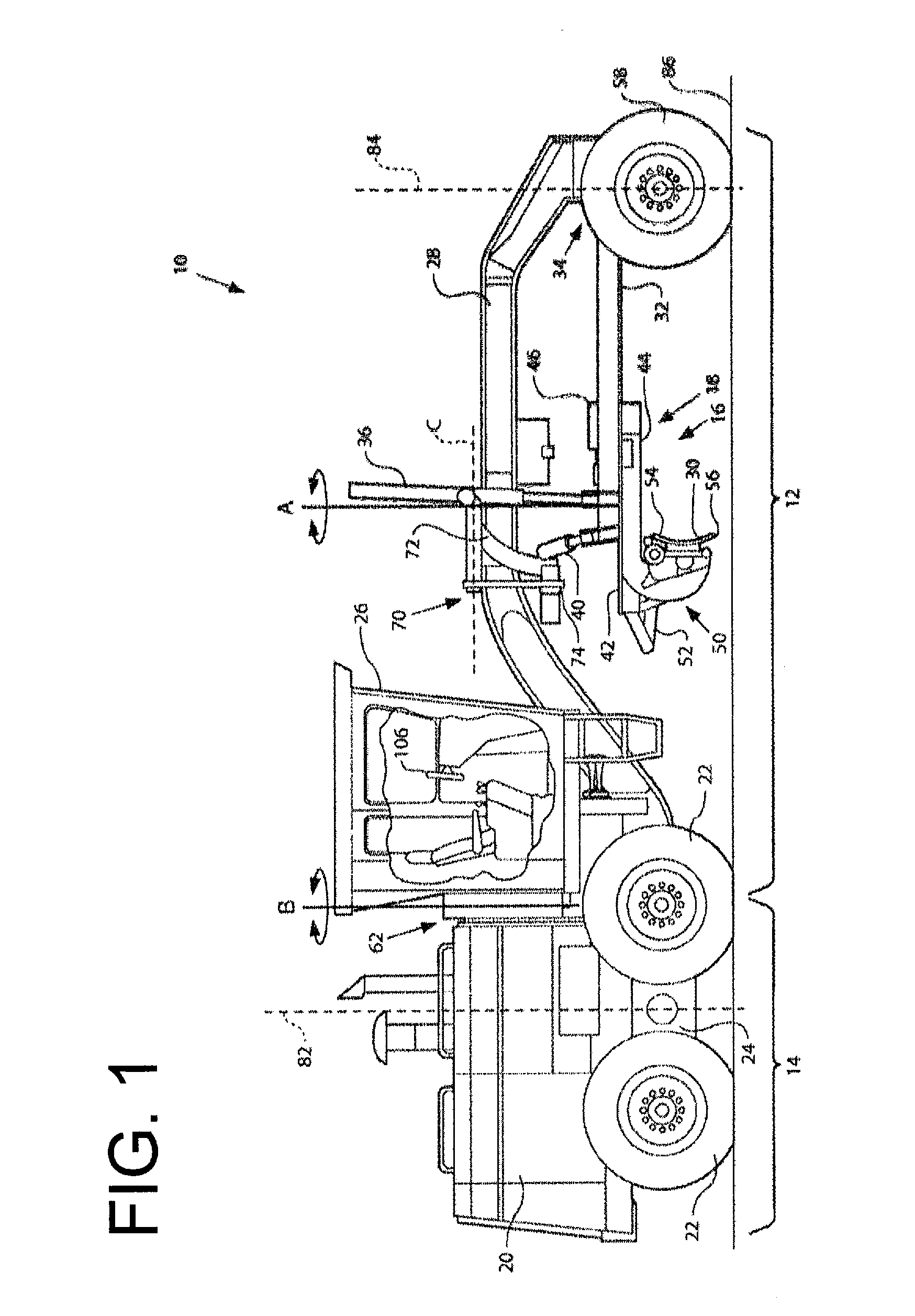

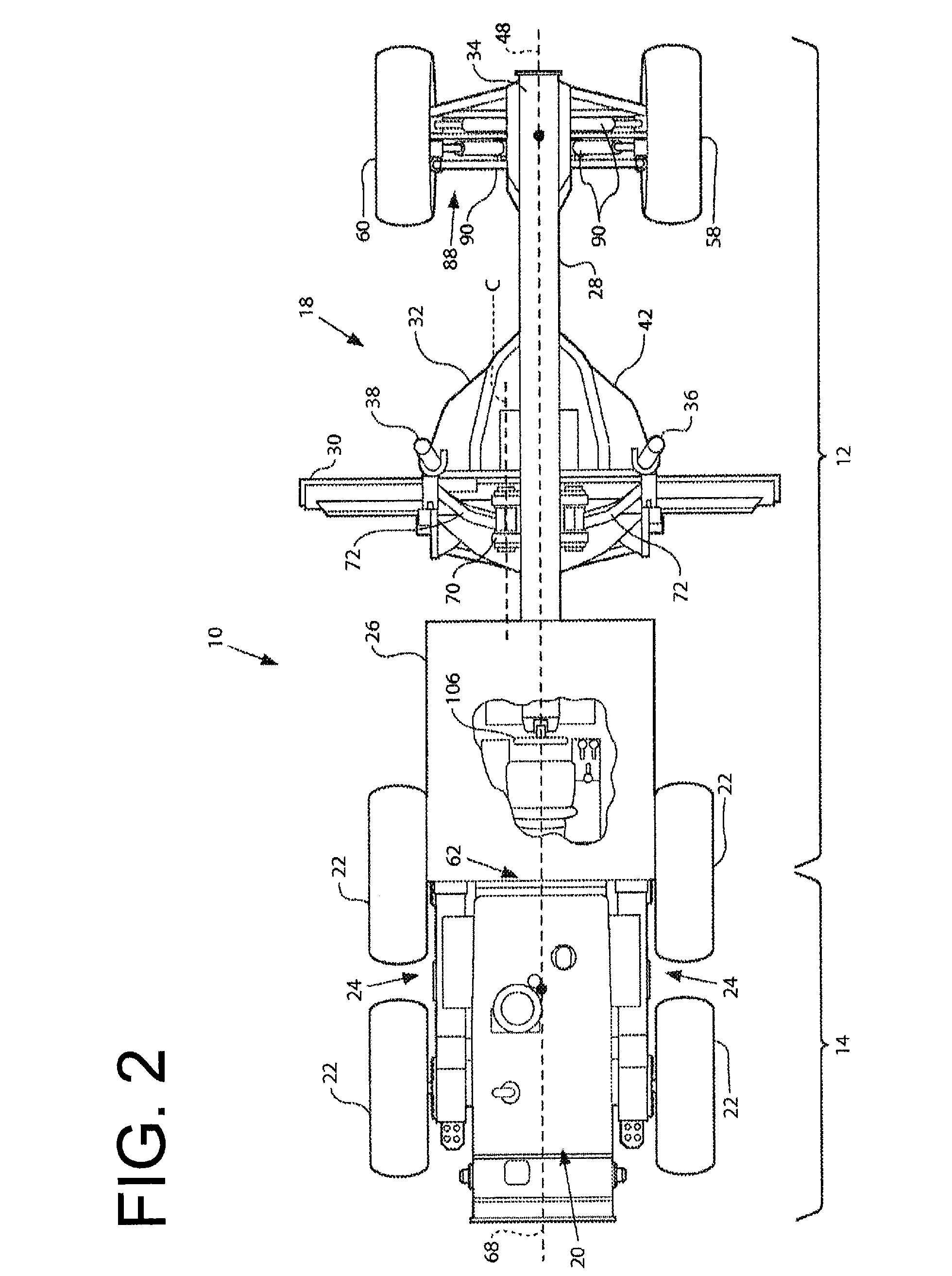

[0023]The present disclosure provides a system and method for motor grader steering and blade control for operations relative to roadway markers such as, but not limited to, curbs and the like. Referring now to FIG. 1 and FIG. 2, there is shown an exemplary motor grader in accordance with one embodiment of the present disclosure. The illustrated motor grader 10 includes a front frame 12, rear frame 14, and a work implement 16. In the context of a motor grader, the work implement 16 is typically a blade assembly 18, also sometimes referred to as a drawbar-circle-moldboard assembly (DCM). The blade assembly 18 may include a separate blade portion and a moldboard portion, and such arrangements will be referred to herein collectively as the blade, moldboard, or DCM.

[0024]The rear frame 14 includes a power source, not shown, contained within a rear compartment 20. The power source is typically operatively coupled through a transmission, not shown, to rear traction devices or wheels 22 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com