Liquid jetting apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

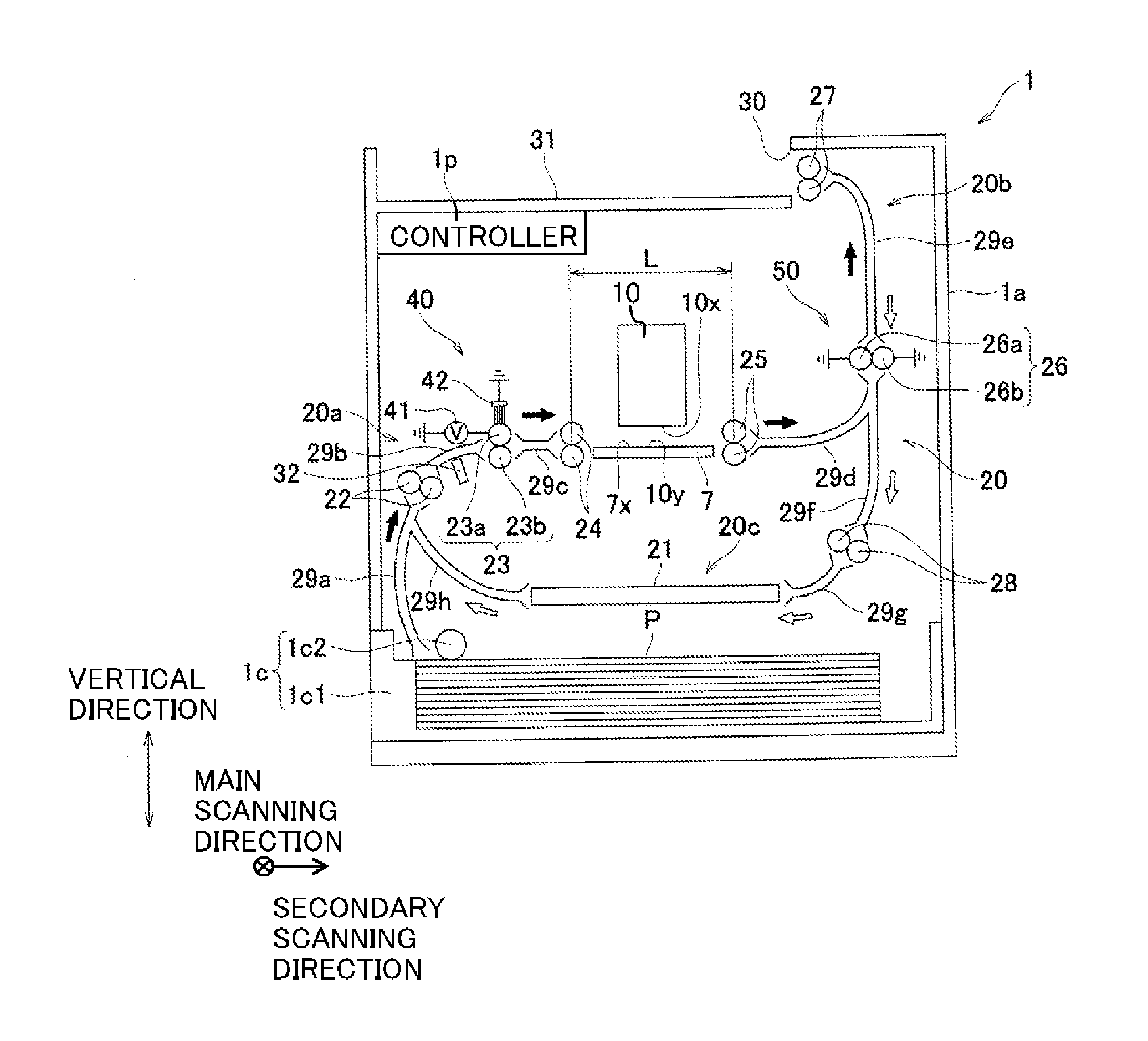

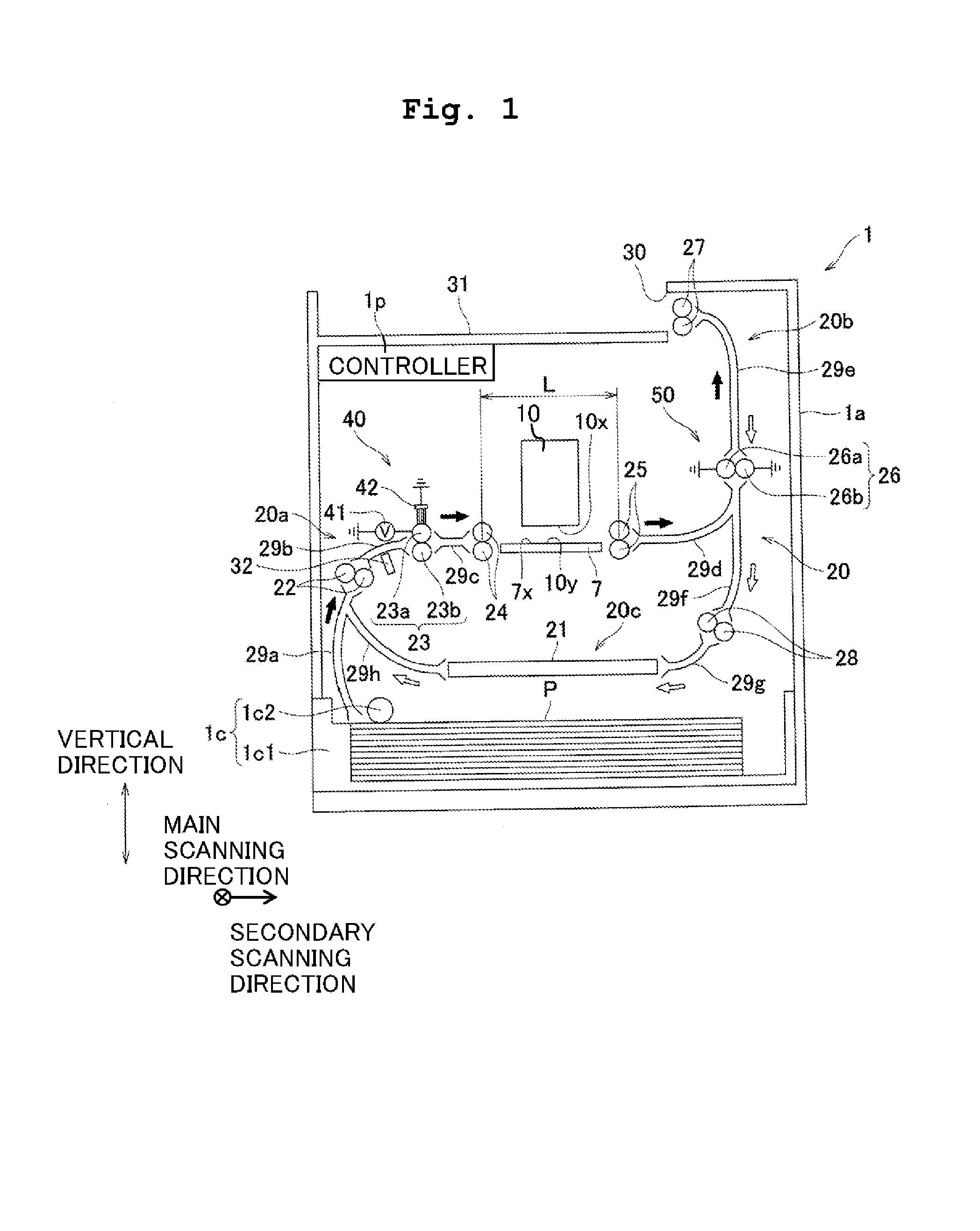

[0023]First, referring to FIG. 1, explanations will be made with respect to an overall construction of an ink-jet printer 1 according to the present teaching.

[0024]The printer 1 has a box-shaped casing 1a. A paper discharge section 31 is provided at the upper side of the top panel of the casing 1a. In the inner space of the casing 1a, a head 10, a platen 7 (an example of a support member), a paper sensor 32, a controller 1p (an example of a controller), a transport section 20, a paper feed unit 1c, and the like are accommodated. In the inner space of the casing 1a, a transport pass through which a paper sheet P is transported is formed from the paper feed unit 1c to the paper discharge section 31 along thick arrows shown in FIG. 1. Further, in the casing 1a, a cartridge (not shown) containing a black ink to be supplied to the head 10 is provided removably. The cartridge is connected to the head 10 via a tube etc., and the ink is supplied to the head 10.

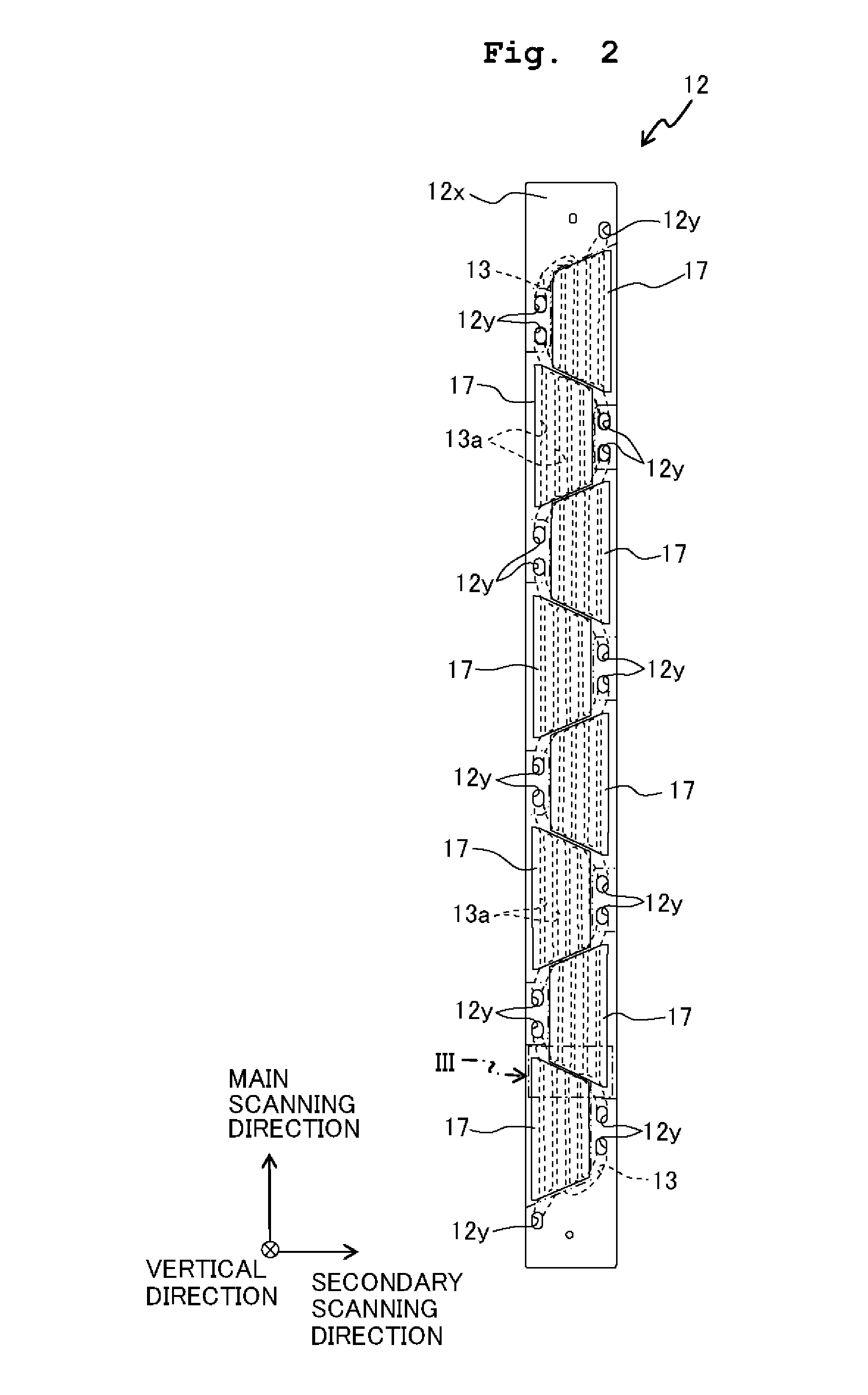

[0025]The head 10 is a line he...

second embodiment

[0068]Subsequently, an explanation will be made about an ink-jet printer 201 according to the present teaching with reference to FIG. 9 and FIG. 10.

[0069]The structures of the charging section and the foreign substance elimination section in the printer 201 of the second embodiment are different from those in the printer 1 of the first embodiment. Other structures in the printer 201 are the same as those in the printer 1 of the first embodiment.

[0070]In the second embodiment, a charging section 240 is constructed of a pair of rollers 223, a sponge 241 (an example of the voltage applying section and a contact-separation member), a solenoid 243 (an example of the contact-separation mechanism), and the electricity removal brush 42 as shown in FIG. 9.

[0071]The pair of rollers 223 includes rollers 223a and 223b. Although illustrations are omitted in FIG. 9 and FIG. 10, a plurality of rollers 223a (an example of the charging member, the contact member and the rotating member) are provided...

third embodiment

[0084]Subsequently, an explanation will be made about an ink-jet printer 301 according to the present teaching with reference to FIG. 11 and FIGS. 12A and 12B.

[0085]The structure of the charging section in the printer 301 of the third embodiment is different from that of the printer 1 of the first embodiment. Other structures in the printer 301 are the same as those in the printer 1 of the first embodiment.

[0086]In the third embodiment, a charging section 340 is constructed of a pair of rollers 323, a power source 341 (an example of the voltage applying section), and a solenoid 343 (an example of the movement mechanism) as shown in FIG. 11.

[0087]The pair of rollers 323 includes rollers 323a (an example of the charging member, the contact member and the second roller) and a roller 323b (an example of the first roller). As shown in FIG. 12A, a plurality of rollers 323a are provided similar to the rollers 23a in the first embodiment (see FIG. 5A), and the plurality of rollers 323a are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com