Beverage brewing system

a technology of brewing system and beer, which is applied in the field of beer brewing system, can solve the problem that the processor cannot operate the brewing system,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

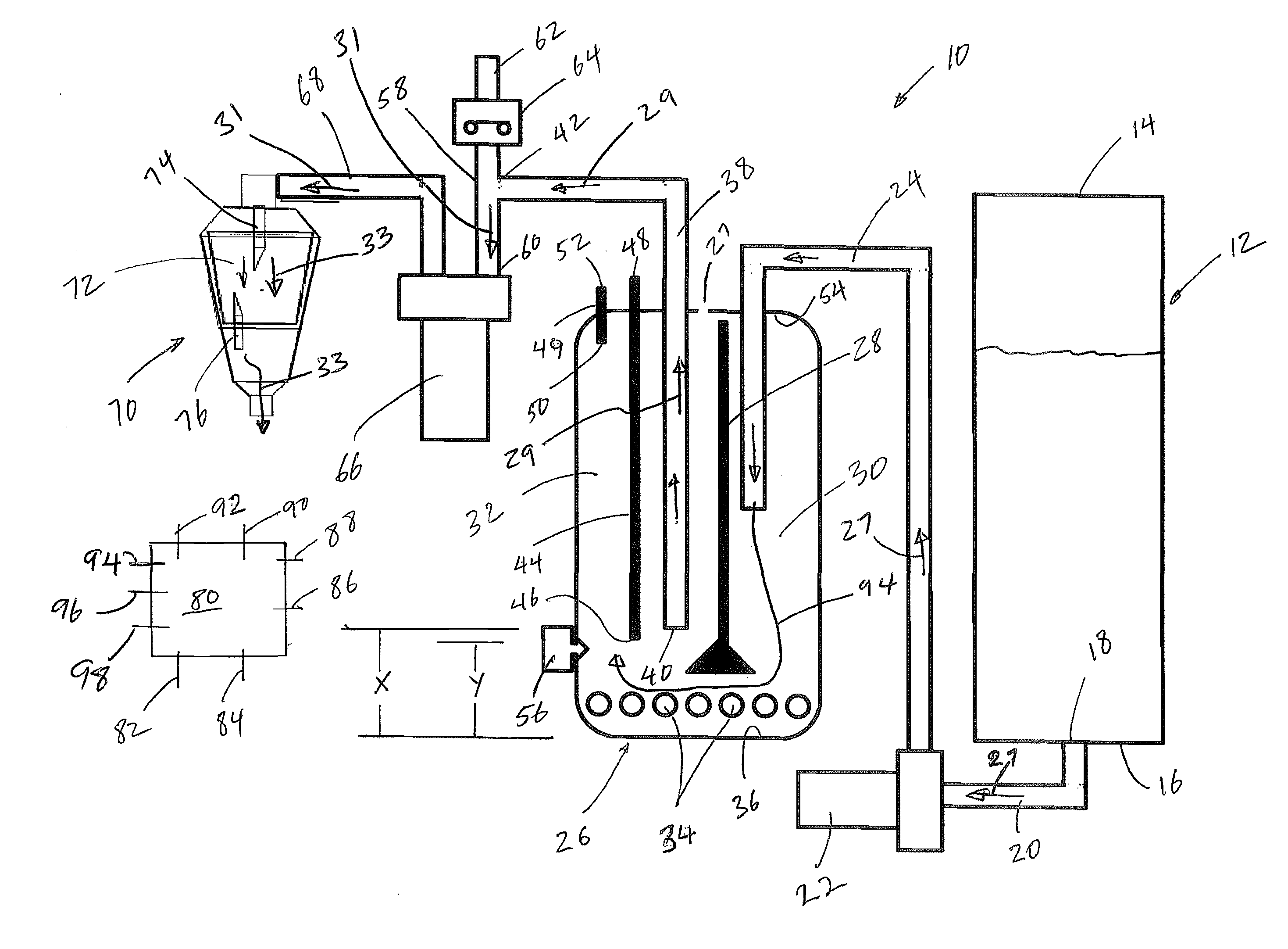

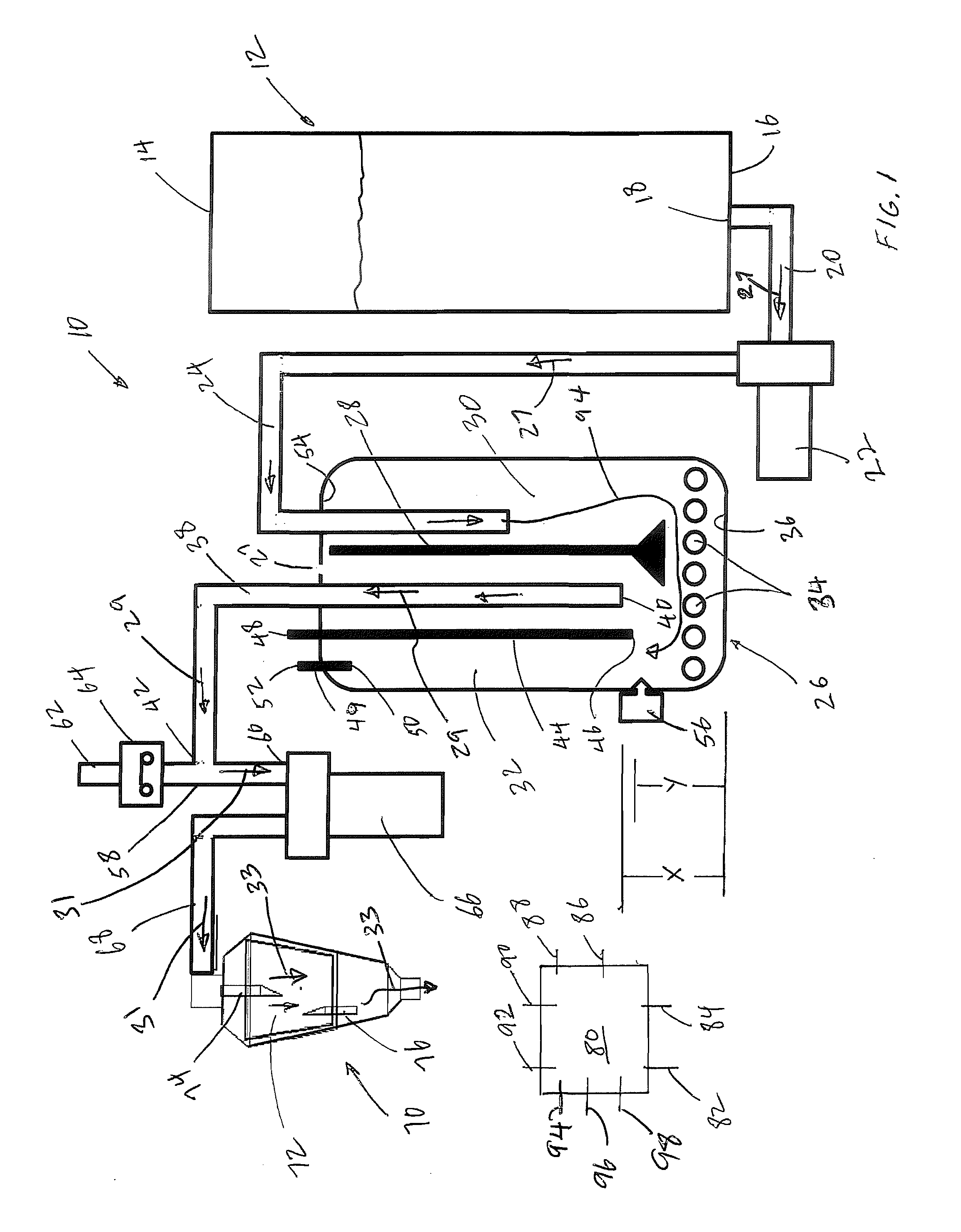

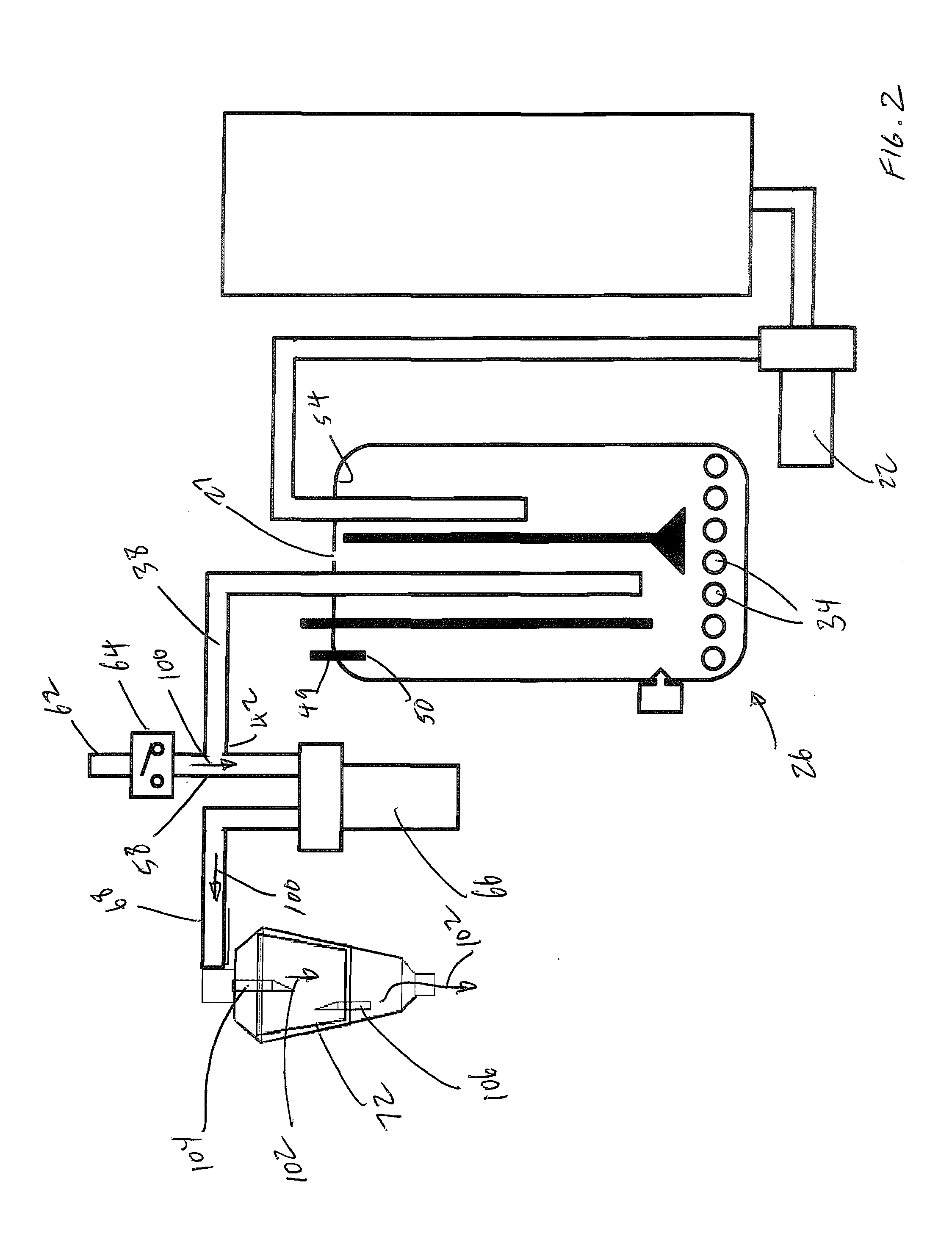

[0031]FIG. 1 shows a schematic diagram of a beverage brewer system 10 having a reservoir 12 adapted to hold fluid such as liquid water to serve a plurality of different beverages such as coffee. The reservoir 12 may have an opening 14 to allow a user to pour liquid into the reservoir 12. The reservoir 12 may have a base 16 with a drain hole 18 to allow the liquid to flow therethrough. A first tube 20 may be coupled to the drain hole 18 to a first pump 22 adapted to pump the water in the reservoir 12 through a second tube 24.

[0032]The system 10 may include a heating member 26 adapted to receive the water from the second tube 24. The heating member 26 may be open to the atmosphere or it may be sealed to the atmosphere. In this embodiment, the heating member 26 may have an opening 27 so that the air in the heating member 26 may be displaced to the atmosphere as water enters the heating member 26 through the second tube 24. This allows the first pump 22 to utilize nominal power to pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com