Electronically-Controlled Tankless Water Heater with Pilotless Ignition

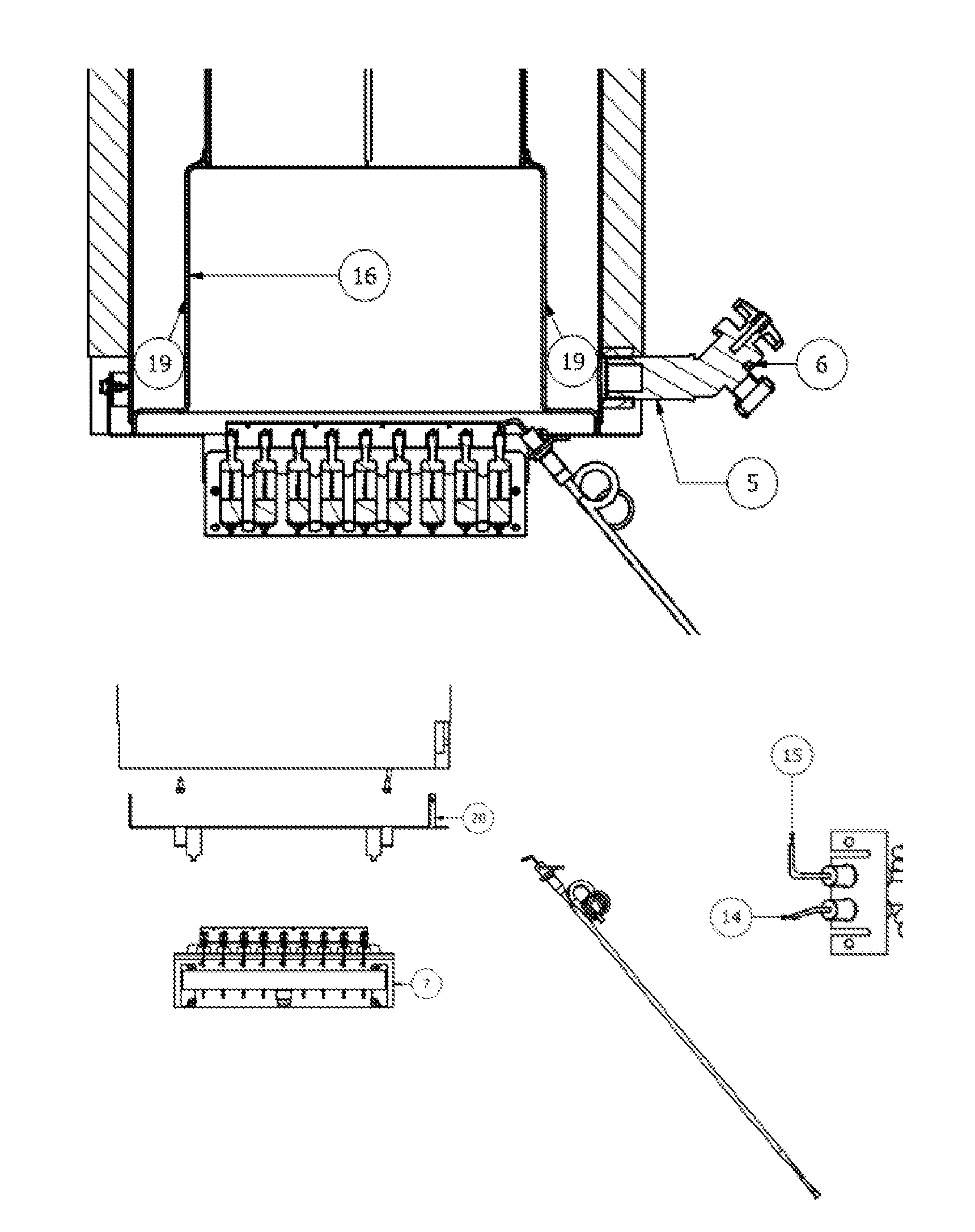

a technology of electric control and water heater, which is applied in the direction of fluid heater, multi-burner assembly, combustion process, etc., can solve the problems of reducing the efficiency of water heaters, destroying equipment, and increasing equipment costs, so as to minimize the heat loss to the exterior of the area, avoid overheating the water inside the equipment, and maximize gas fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

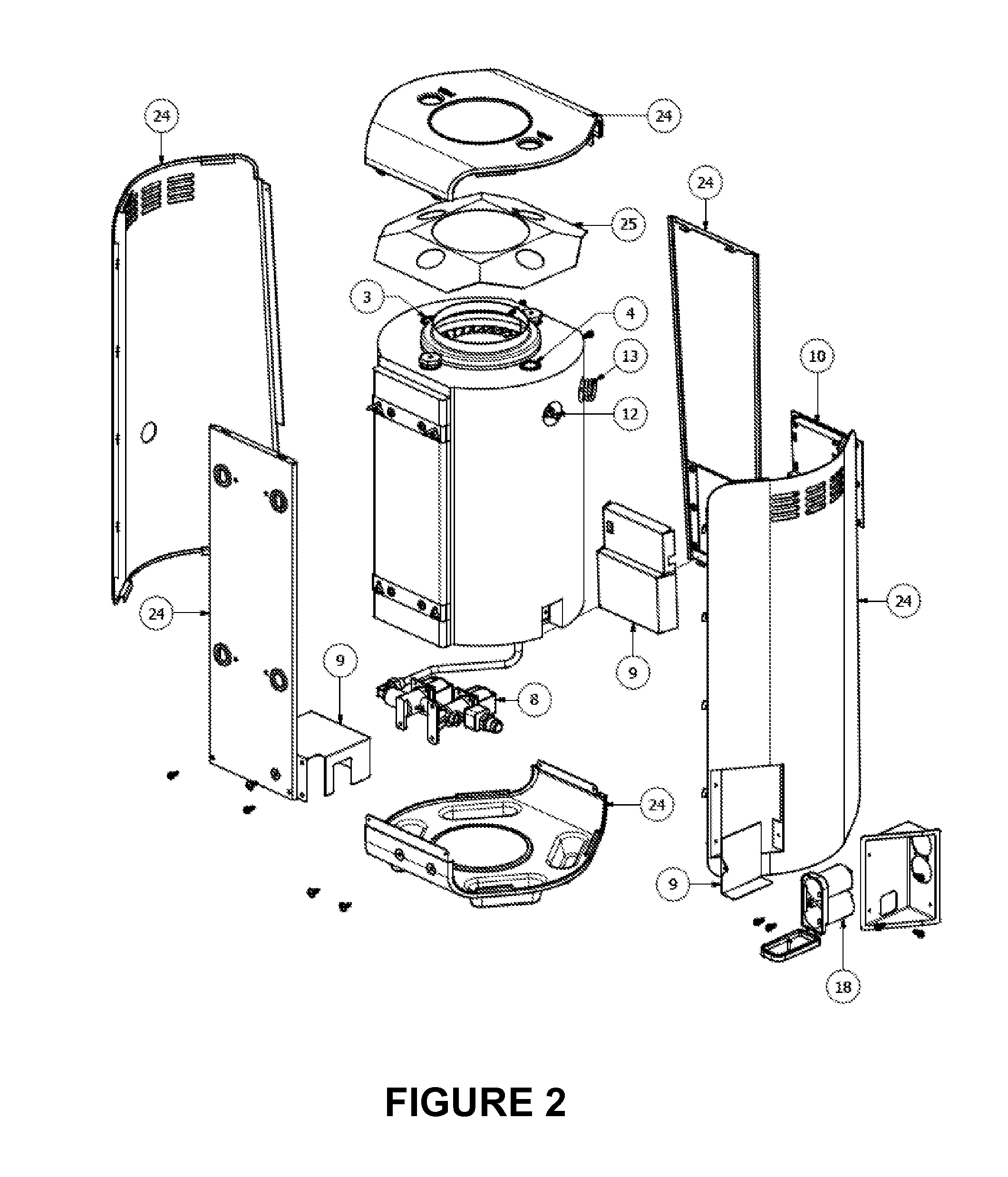

[0017]Reference is now made to particular embodiments of the invention, one or more examples of which are illustrated in the drawings. Each embodiment is provided by way of explanation of the invention, and not as a limitation of the invention. For example, features illustrated as described as part of one embodiment may be used with another embodiment to yield still a further embodiment. It is intended that the present invention include these and other modifications and variations.

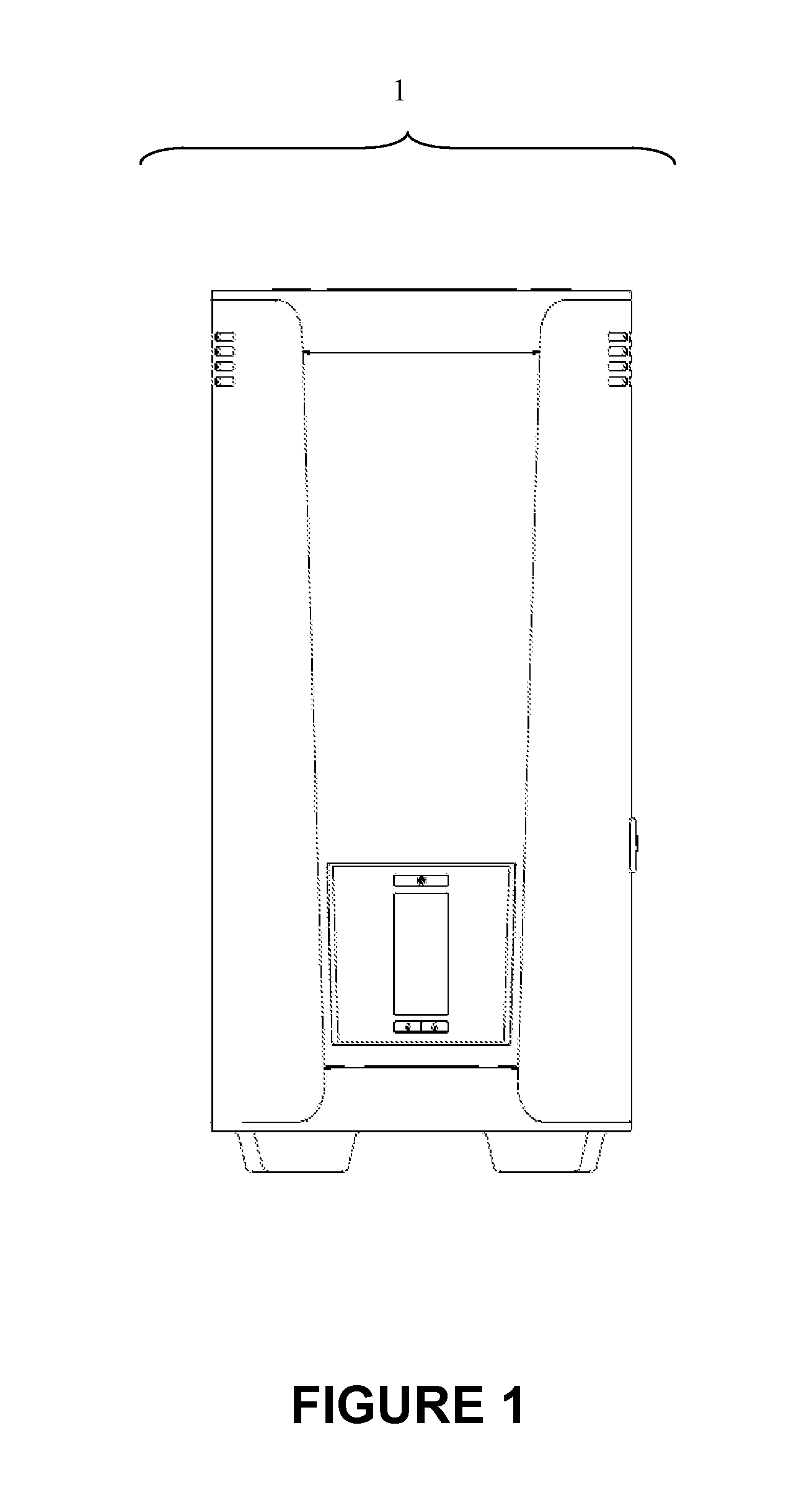

[0018]This invention's water heater (1) shown in FIG. 1 is designed to withstand a pressure greater than 1.0 MPa. The steel water tank (2) is porcelainized on the areas in contact with water to prevent corrosion.

[0019]The cold water inlet (3) is located to the upper-right of the water tank (2), likewise, the hot water outlet (4) is located at the upper left of the tank (2). Additionally, on the lower part of the water tank (2), there is a coupling that connects the water tank (2) to the exterior, allowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com