Toy flying disc with baffle

a technology of flying discs and discs, which is applied in the field of toys and amusement devices, can solve the problems of increasing packaging and shipping costs, reducing the area of the surface, and reducing the imprinting of surfaces, so as to achieve the effect of simple assembly, easy affixed without distortion, and low cost of shipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

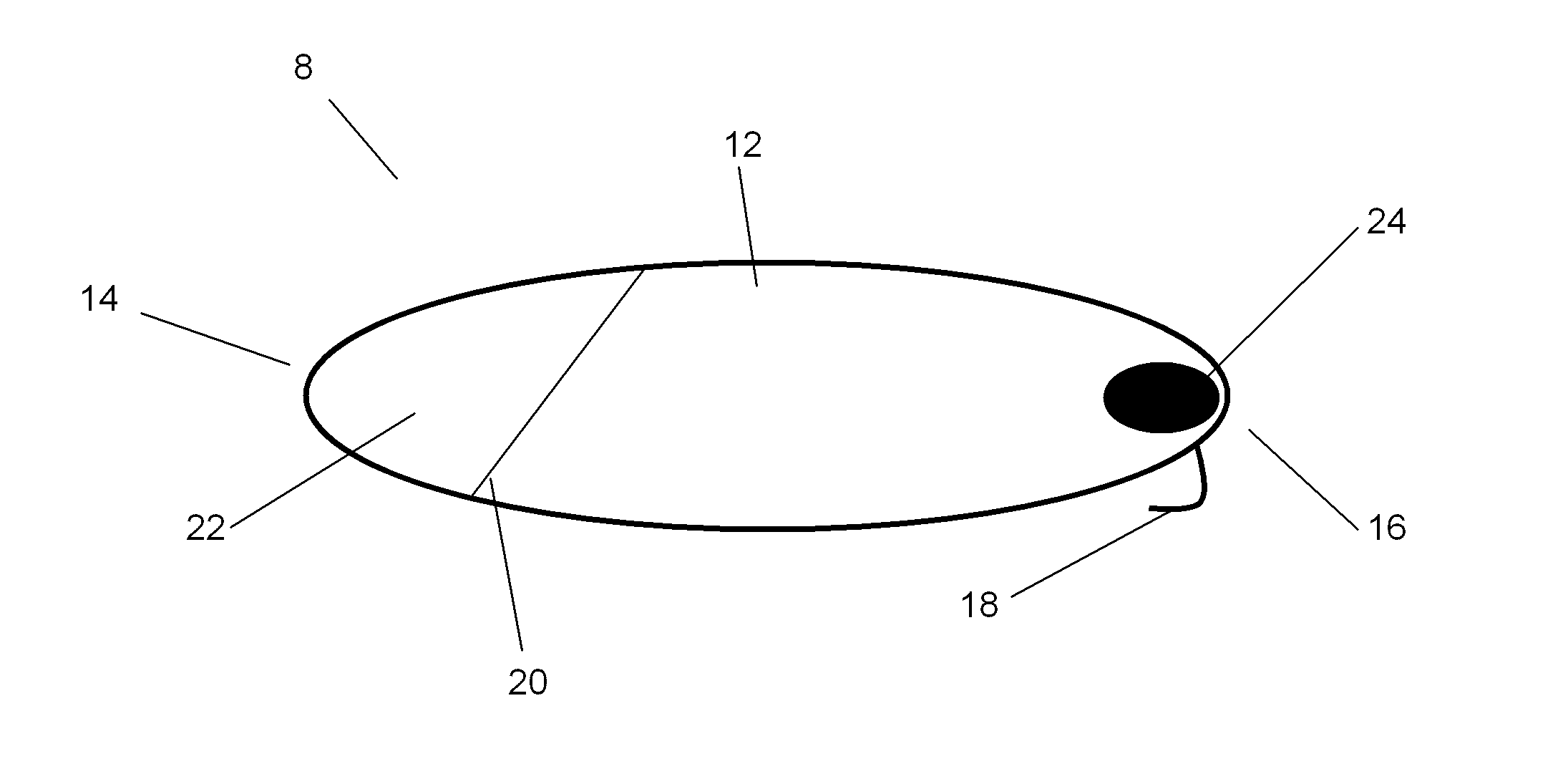

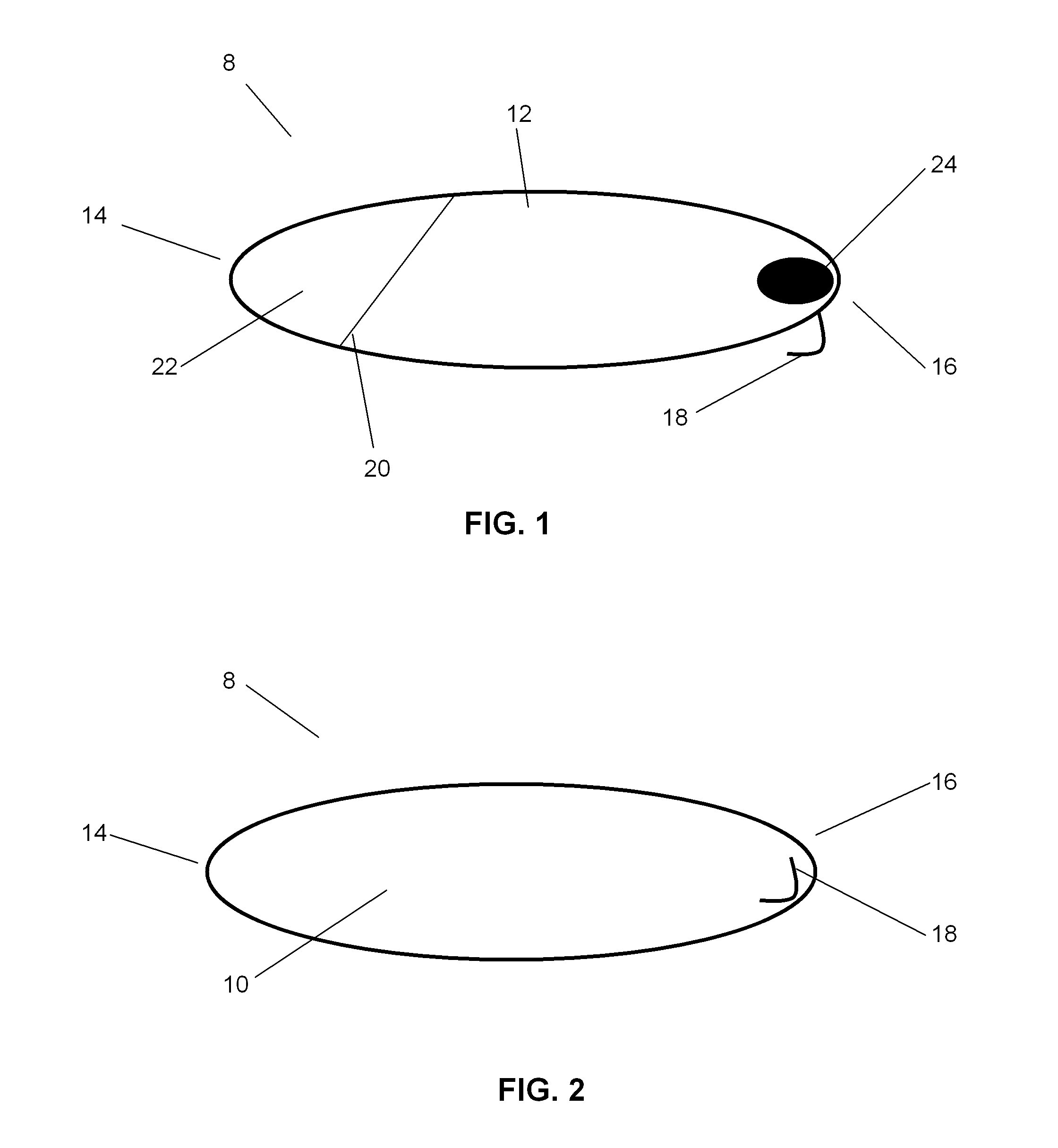

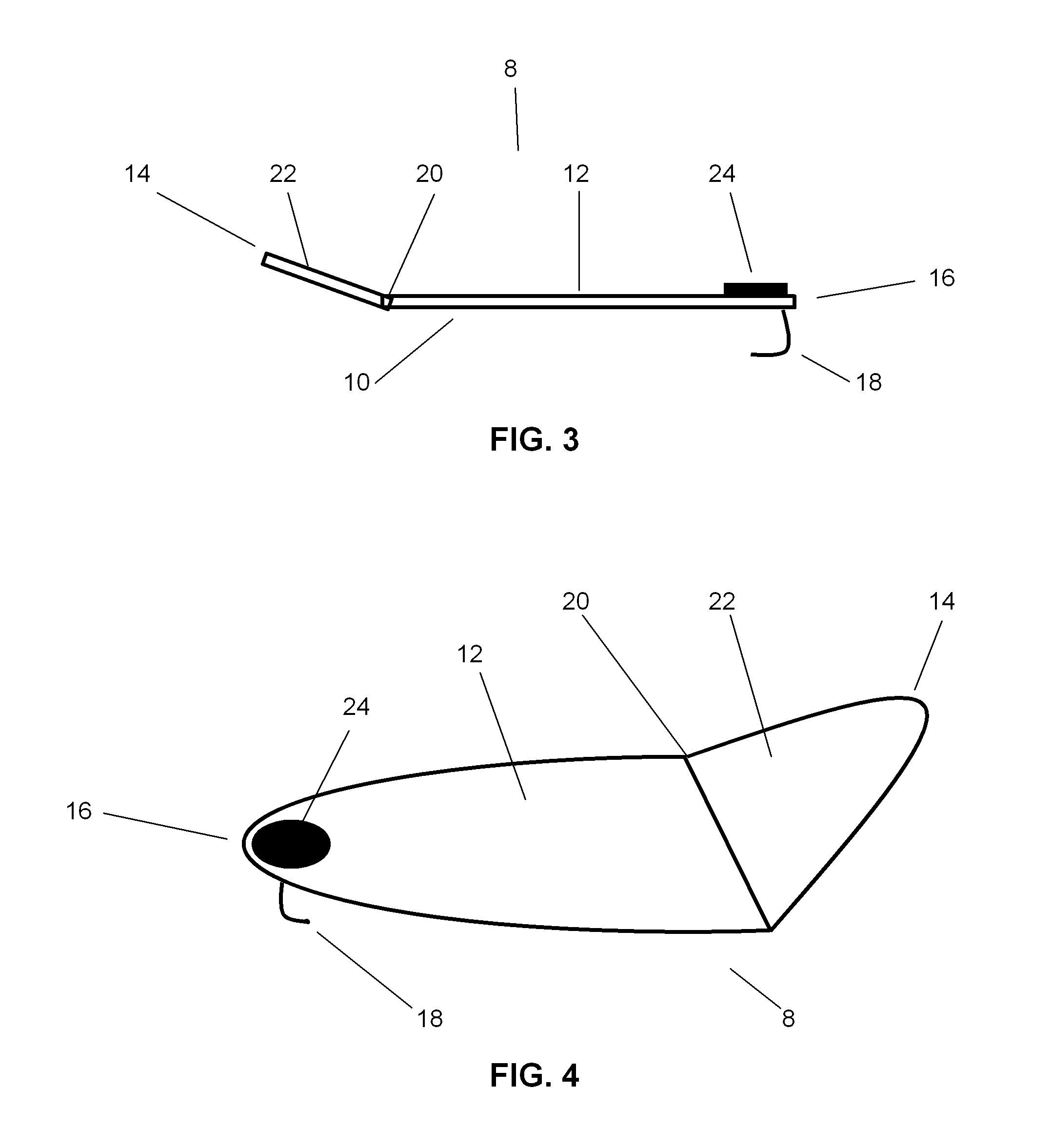

[0056]In the illustrated embodiment of FIGS. 1-4, there is shown a craft 8 having an upper surface 12 and lower surface 10. At a point near the trailing edge 14, a linear indentation 20 is formed in the upper surface 12 such that the rearmost portion of the disc can be bent upwardly, forming a baffle 22, transverse to the direction of flight. In the preferred embodiment, a flat magnet, comprising the weight 24, is affixed near the leading edge 16, on the upper surface 12 of the craft 8.

[0057]In another embodiment, a depending hook 18 is positioned near the leading edge 16 of the craft 8 and attached to the lower surface 10 of the craft 8, opposite the weight 24.

[0058]Although other suitable, lightweight materials could be used, it is presently preferred that the body of the craft 8 be made of Styrofoam, such as that commonly found in disposable dinnerware.

[0059]In the preferred embodiment the disc is cut from a Hefty® Disposable Dinnerware Plate 2 mm thick. A self-adhesive depending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com