Fan nozzle

a fan nozzle and nozzle technology, applied in the field of nozzles, can solve the problems of creating wear points at the transition, all have a common drawback, and turbulence and wear, and achieve the effects of reducing hot spots in the media flow outlet, reducing turbulence and wear, and improving the performance of the fan nozzl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

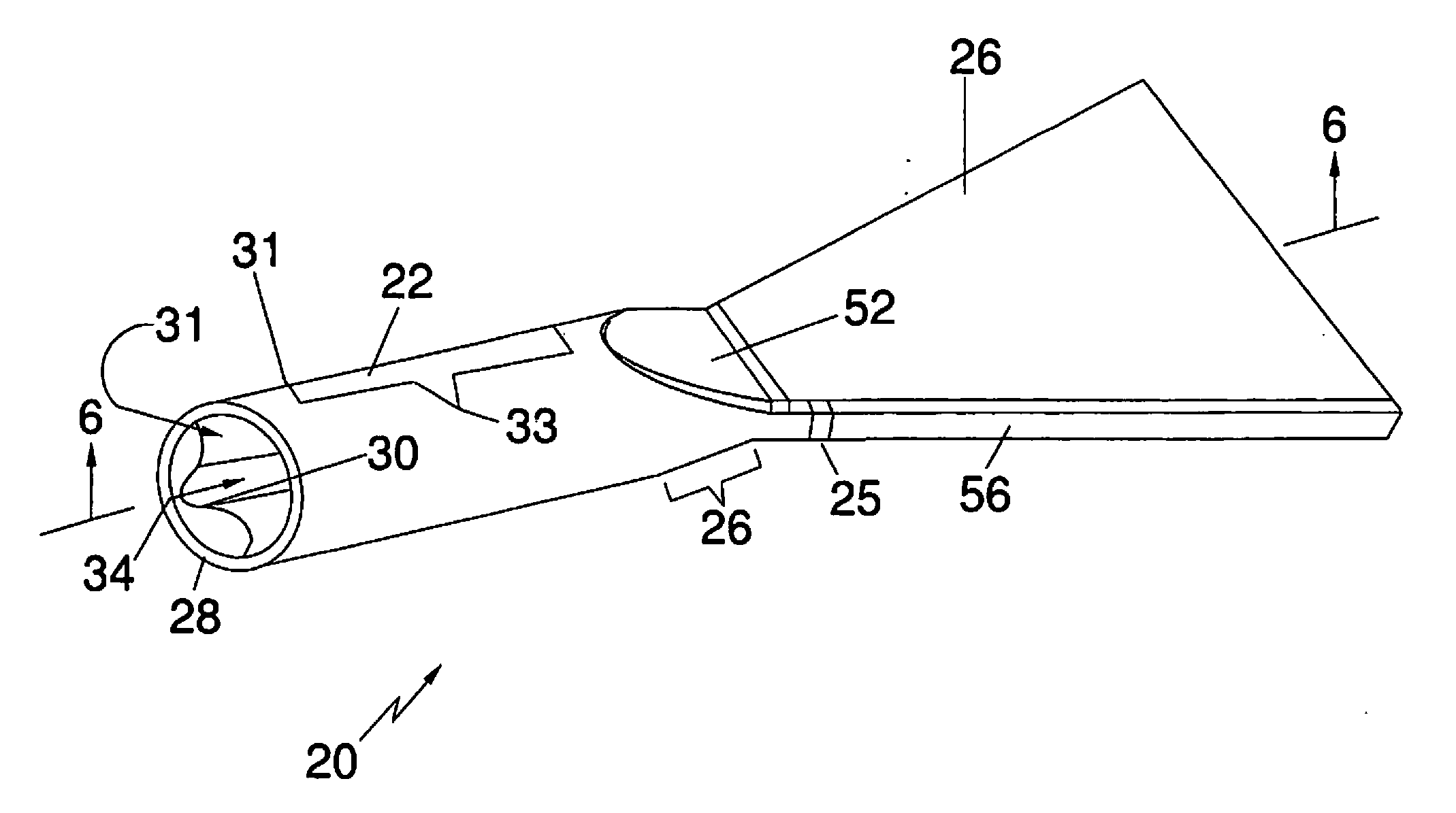

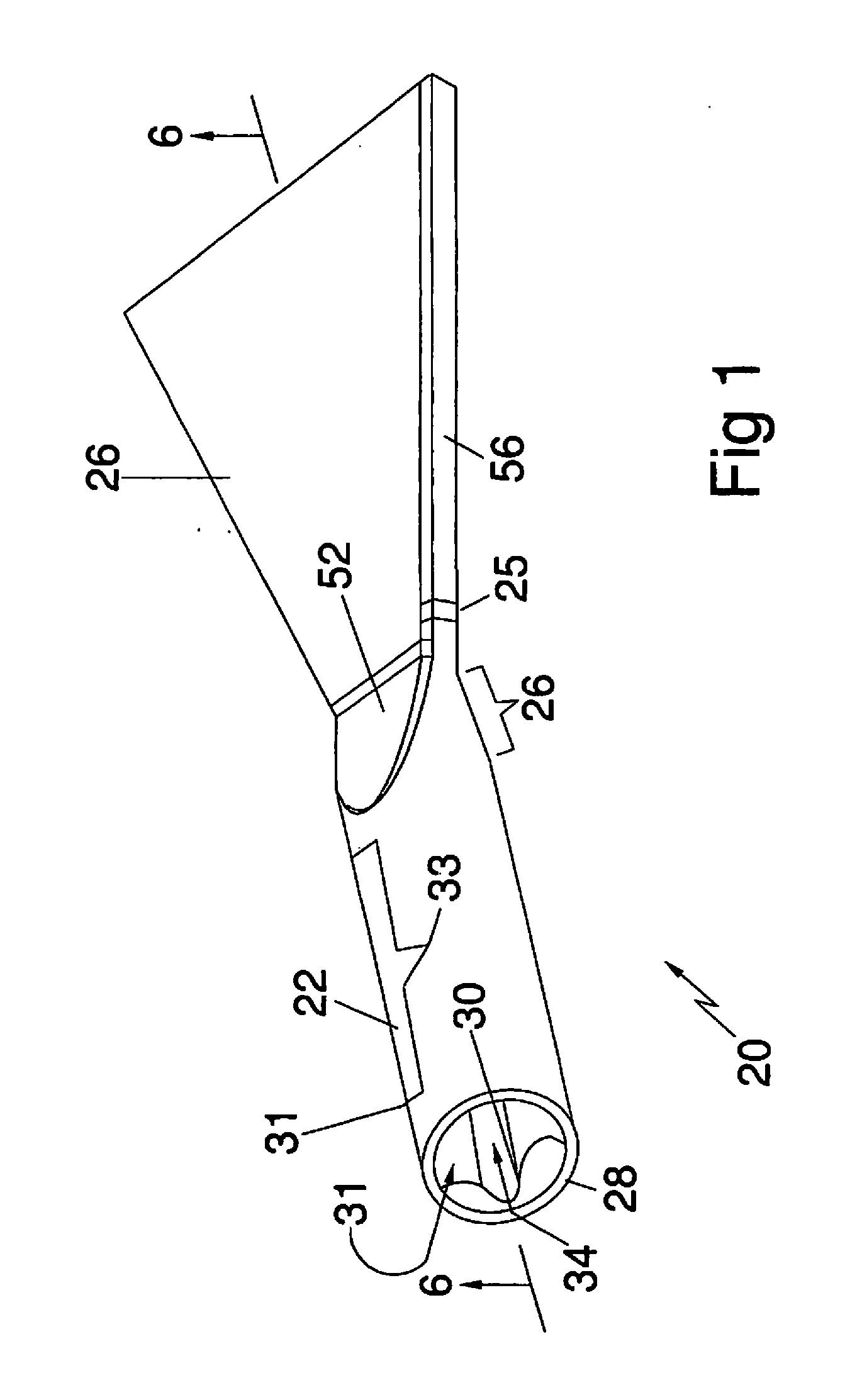

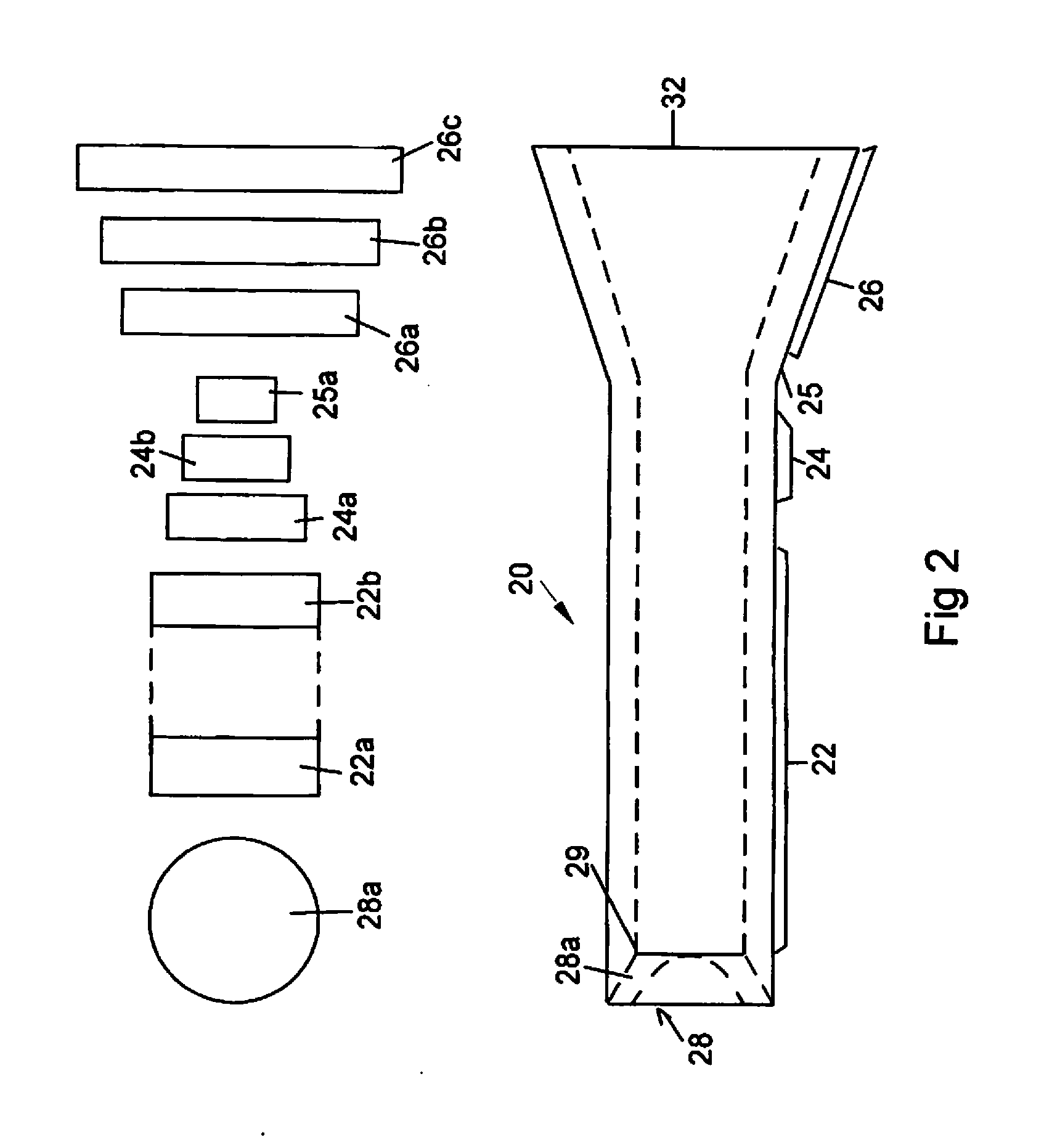

[0031]With specific reference to FIG. 1, the fan nozzle of the subject invention comprises a longitudinal body 20. The fan nozzle is divided into three main sections, the inlet section 22, the transition section 24 and the expansion section 26. A cross-sectional view of the nozzle, taken along line 6-6 of FIG. 1 is shown in FIG. 6. The inlet 28 of the nozzle is adapted to be coupled to a source of pressurized media and is typically of a generally circular cross-section, but may be modified, as at 30, to receive a connector on the source (not shown). Inwardly of the inlet 28, the inlet section 22 is of a rectangular cross-section, as shown in FIGS. 2-5, for distributing the pressurized air or other fluid and the abrasive throughout the full cross-sectional area of the nozzle. Specifically, the inlet end 28 of the nozzle provides a transition from the circular connector at 28a to a rectangular cross-section at 31, with the remainder 33 of the inlet section being of rectangular cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com