Piezoelectric generator, sensor node, and method of manufacturing piezoelectric generator

a piezoelectric generator and sensor node technology, applied in the direction of generator/motor, piezoelectric/electrostrictive transducer, transducer type, etc., can solve the problems of difficult low-profiling and cost reduction, and achieve low cost, efficient generation of electricity, and enhanced freedom of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Configuration of Piezoelectric Generator

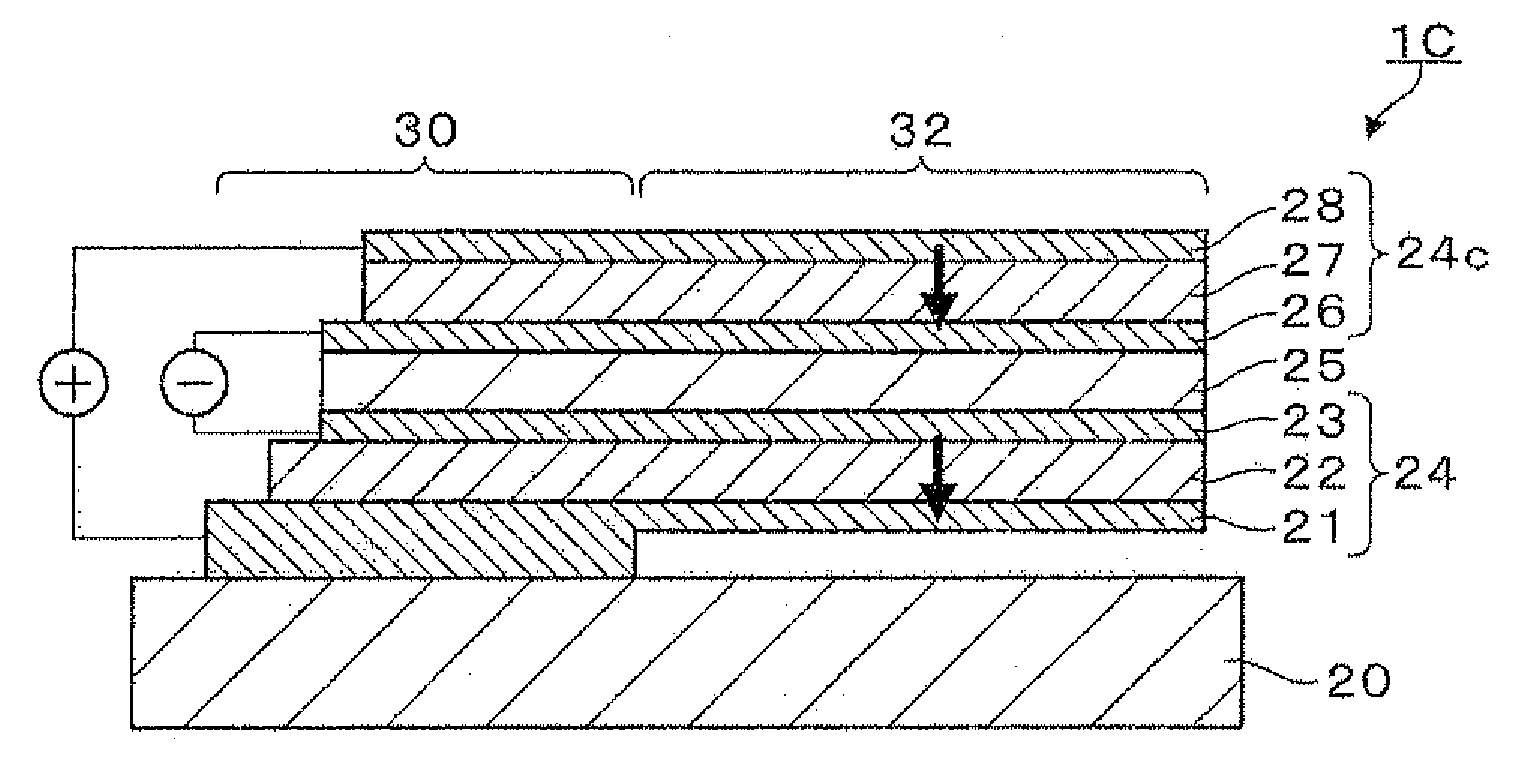

[0038]Firstly, a schematic configuration of the piezoelectric generator according to a first embodiment of the invention will be explained with reference to FIGS. 1A and 1B. FIGS. 1A and 1B are schematic diagrams showing a schematic configuration of the piezoelectric generator according to the first embodiment. For details, FIG. 1A is a schematic plan view of the piezoelectric generator, and FIG. 1B is a schematic cross-sectional view along the line A-A shown in FIG. 1A.

[0039]As shown in FIGS. 1A and 1B, the piezoelectric generator 1 according to the first embodiment is provided with a base body 20, and a piezoelectric transducer 24 including a first electrode 21, a piezoelectric body 22, and a second electrode 23 disposed in a stacked manner sequentially on the base body 20. The base body 20 is made of a ceramic material including the same component as the piezoelectric body 22. In the present embodiment, the base body 20 is made of the same ...

second embodiment

Configuration of Piezoelectric Generator

[0078]Then, a configuration of a piezoelectric generator according to a second embodiment will be explained with reference to FIGS. 6A and 6B. FIGS. 6A and 6B are schematic diagrams showing a schematic configuration of the piezoelectric generator according to the second embodiment. For details, FIG. 6A is a schematic plan view of the piezoelectric generator, and FIG. 6B is a schematic cross-sectional view along the line A-A shown in FIG. 6A.

[0079]The piezoelectric generator 2 according to the second embodiment is different from the piezoelectric generator 1 according to the first embodiment in the point that a weight 29 is disposed on the vibrating section 32, and is substantially the same in the rest of the configuration. Therefore, in the second embodiment, the constituents common to the first and second embodiments are denoted with the same reference symbols, and the explanation therefor will be omitted.

[0080]As shown in FIGS. 6A and 6B, th...

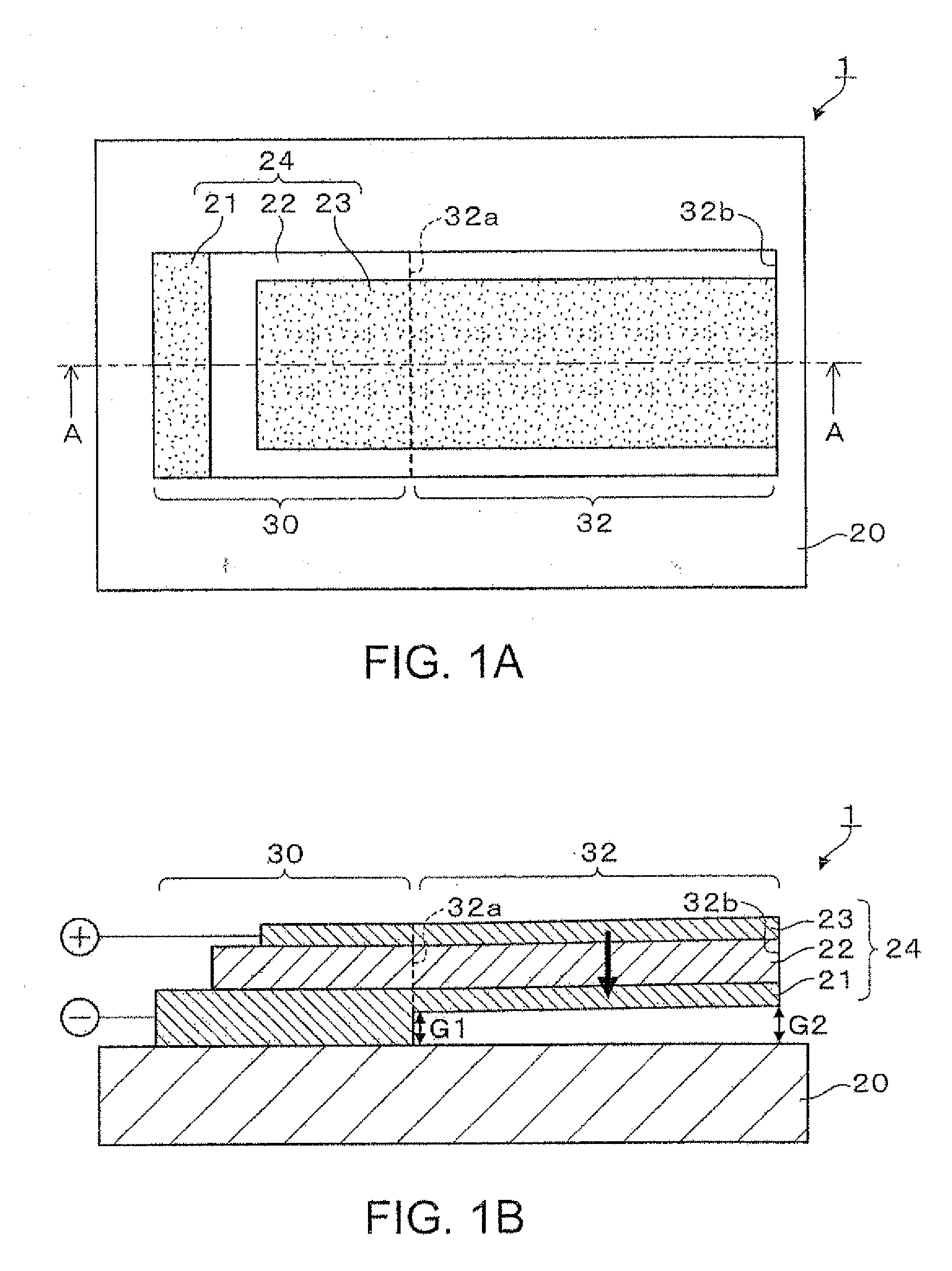

first modified example

[0089]A piezoelectric generator 1A shown in FIG. 7A is further provided with a piezoelectric body 27 and a third electrode 28 stacked on the piezoelectric transducer 24 (the first electrode 21, the piezoelectric body 22, and the second electrode 23). In the piezoelectric generator 1A, a piezoelectric transducer 24a is composed of the second electrode 23, the piezoelectric body 27, and the third electrode 28. The second electrode 23 is also functions as the electrode in the piezoelectric transducer 24a. Therefore, the piezoelectric generator 1A is different from the piezoelectric generator 1 according to the first embodiment in a point that the piezoelectric transducer 24a stacked on the piezoelectric transducer 24 is provided.

[0090]According to the piezoelectric generator 1A, the electric energy due to the external vibration can be obtained from each of the plurality of piezoelectric transducers 24, 24a stacked on the base body 20. As indicated by the arrows in FIG. 7A, since the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com