Food barrier

a technology for separating wet fixings and dry fixings, applied in the field of food packaging, can solve the problems of cumbersome apparatus, unappetizing, cumbersome, etc., and achieve the effect of avoiding a single, unsightly and unappetizing step, and avoiding a single, unnecessary step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The following detailed description is of the best currently contemplated modes of carrying out exemplary embodiments of the invention. The description is not to be taken in a limiting sense, but is made merely for the purpose of illustrating the general principles of the invention, since the scope of the invention is best defined by the appended claims.

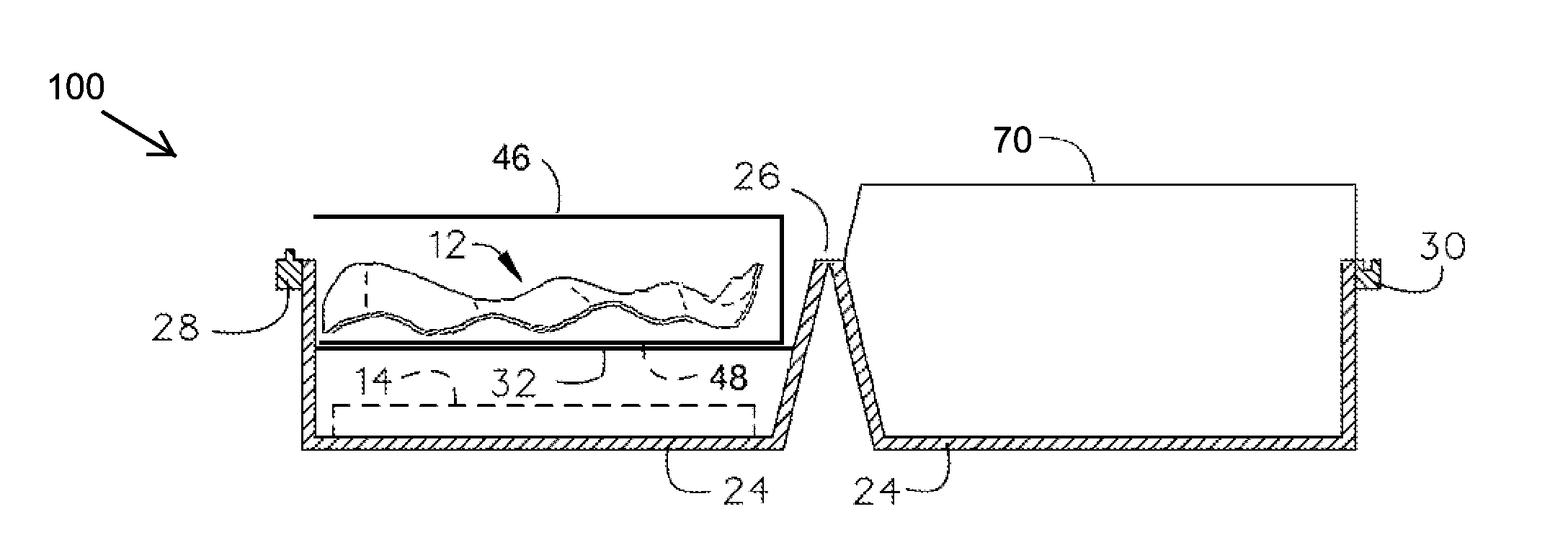

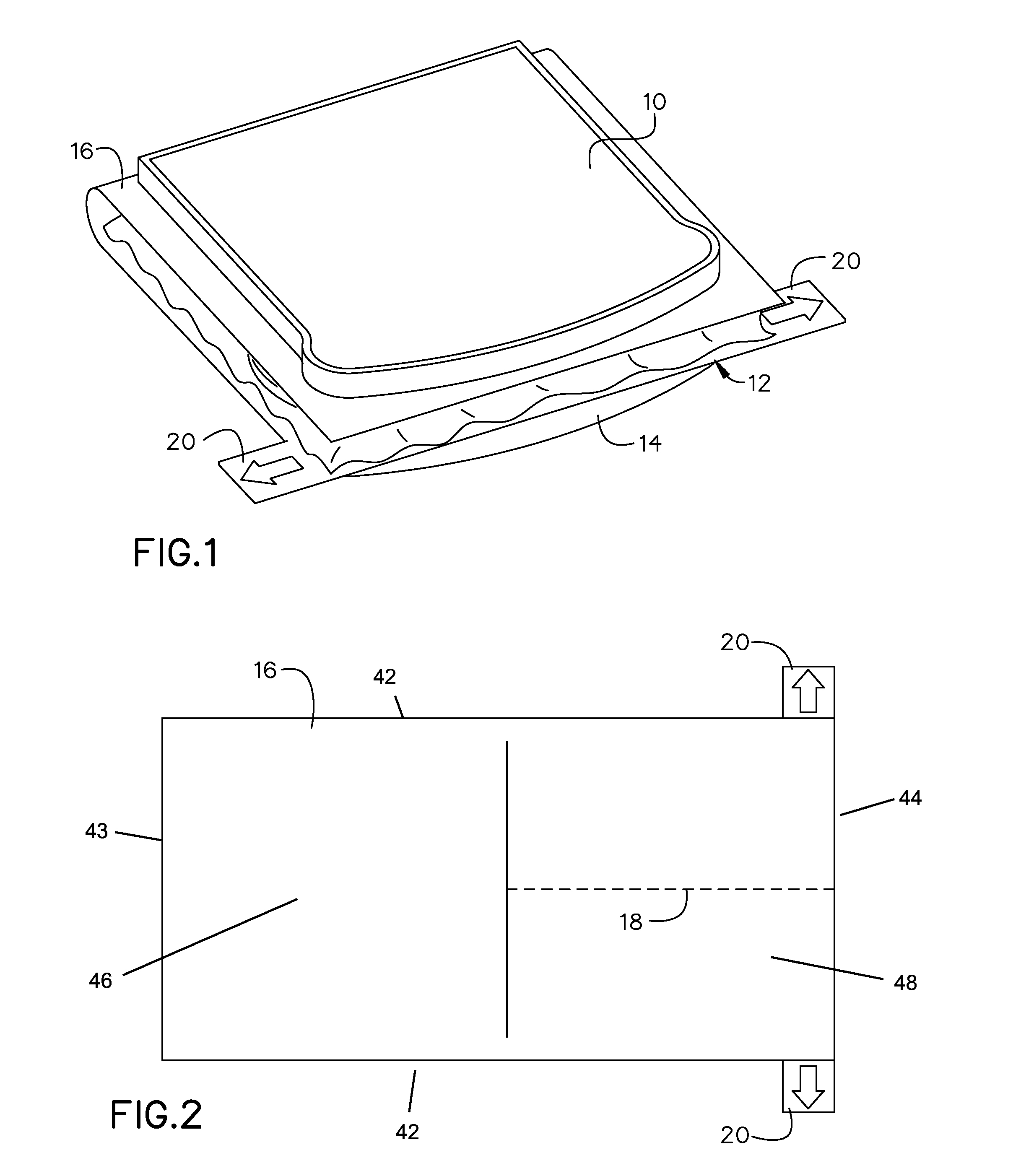

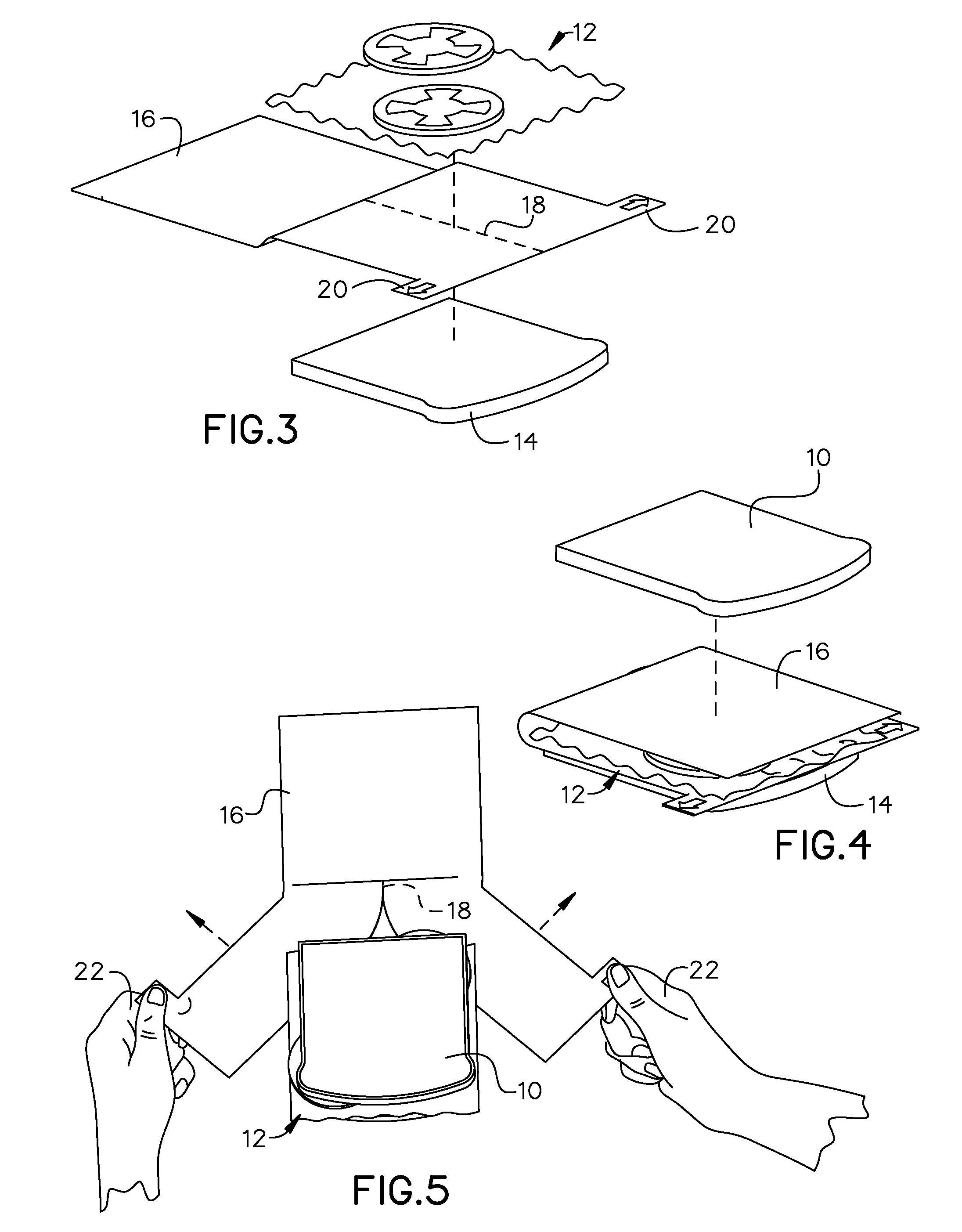

[0018]Broadly, an embodiment of the present invention provides a barrier sheet. The barrier sheet may have a first half and a second half. The second half may include a perforation bisecting the second half into two approximately equal quarters. Each of the two quarters may form a pull tab near the rectangular corners. A user may easily and conveniently assemble a food product having at least one wet fixing, a first portion of dry fixings and a second portion of dry fixings, whereby the barrier sheet sandwiches the at least one wet fixing between the first and second portion of dry fixings: the user may place the second half in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com