Monofilament yarn for a paper machine clothing fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

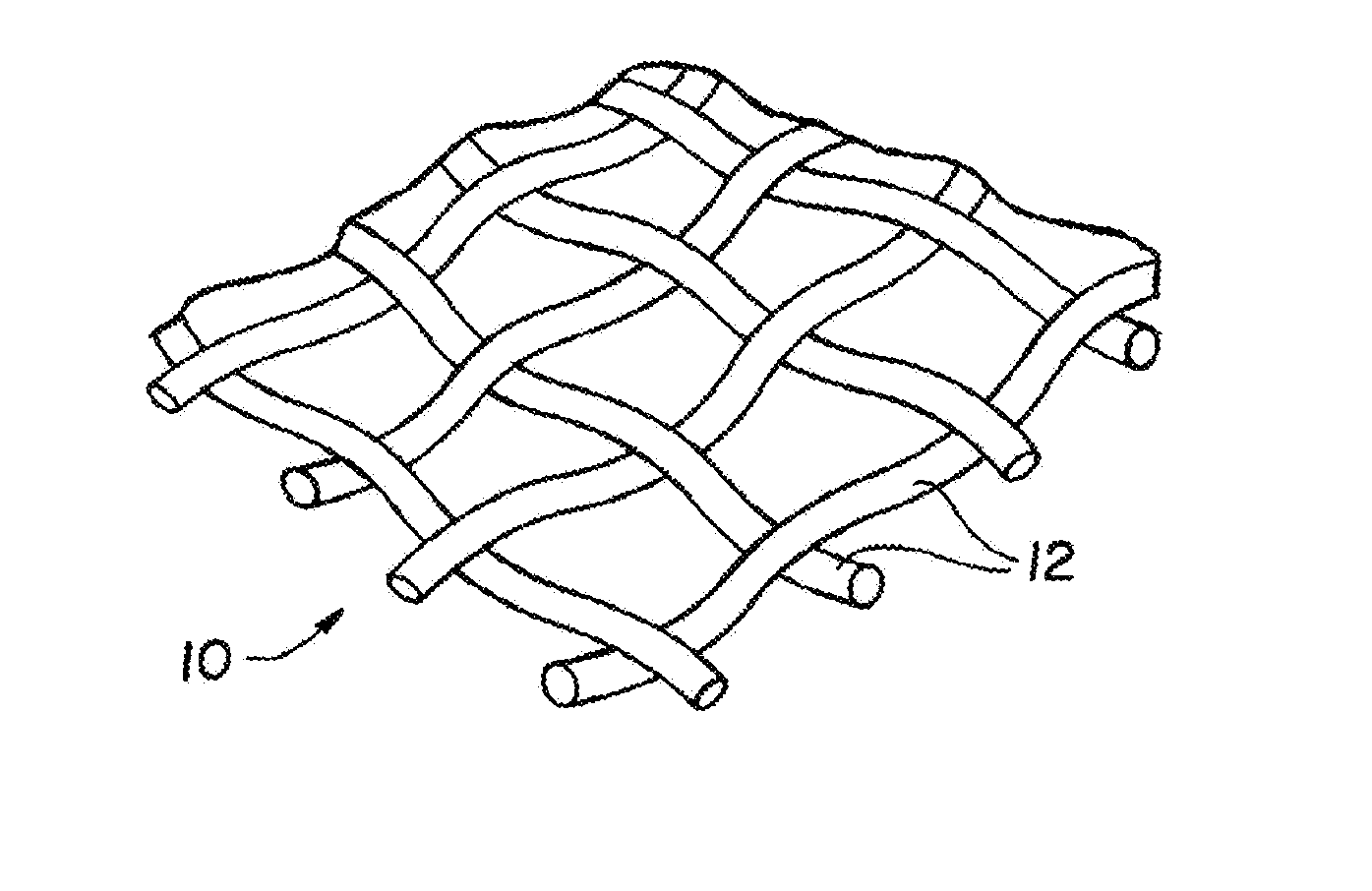

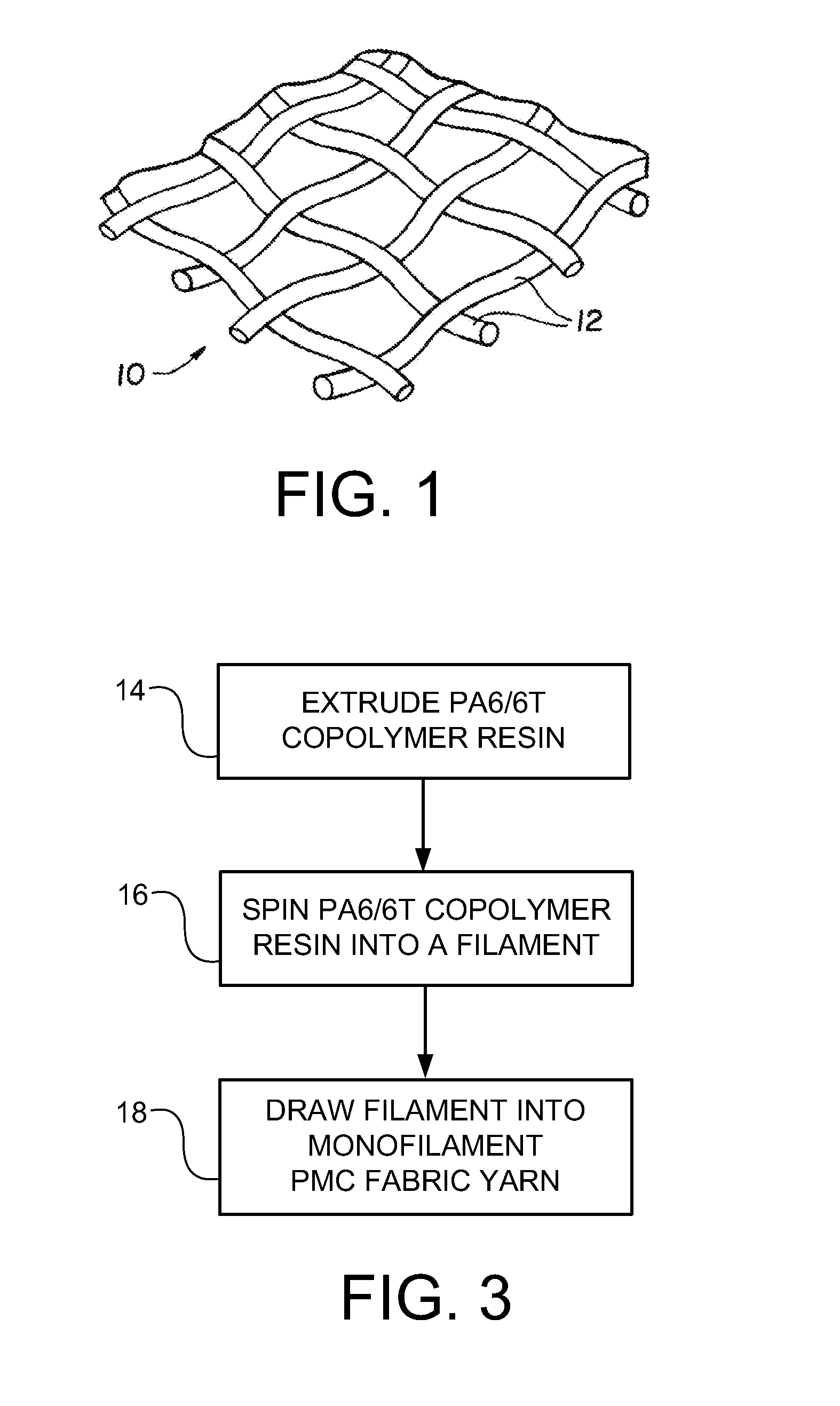

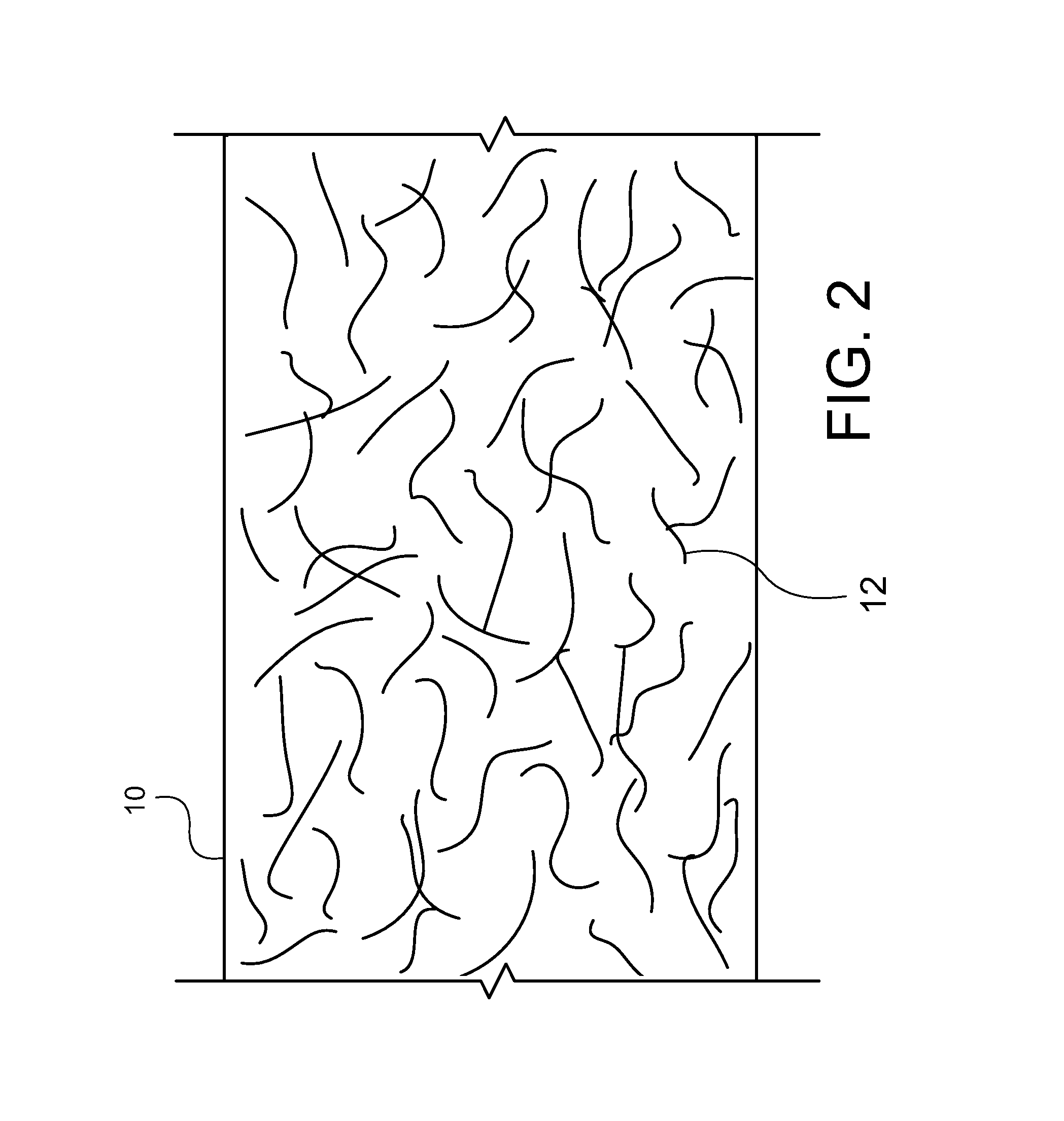

Image

Examples

example

[0023]Table 1 below shows a comparison of the tensile properties of monofilament yarns produced with standard polyamide resins and a monofilament yarn produced with the PA6 / 6T copolymer resin according to the present invention. ASTM D2256-97 method was used to carry out the tensile testing of the yarns. The water absorption of the yarns was measured according to ASTM D570. The yarns were submerged in distilled water at approximately 23° C. for 24 hours. The samples were then removed, pat dried using lint free cloth and weighed. Further, the abrasion resistance of the yarns was measured using the squirrel cage method, which consists of the use of a rotating drum of metal wires which are aligned perpendicular to the polymer strands. A pretension is used on each polymer strand prior to starting the drum. During the test, the strands are continually abraded by the rotation of the drum and the strand's abrasion resistance is quantified by the number of cycles it takes for the strand to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com