Element for performing sports facility stands and sports faility stand performed by means of said element

a technology for sports facilities and elements, applied in treads, treads, public buildings, etc., can solve the problems of large increase in related costs and implementation time, large and often too high utilization cost, and the weight of prefabricated modules' own weight,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

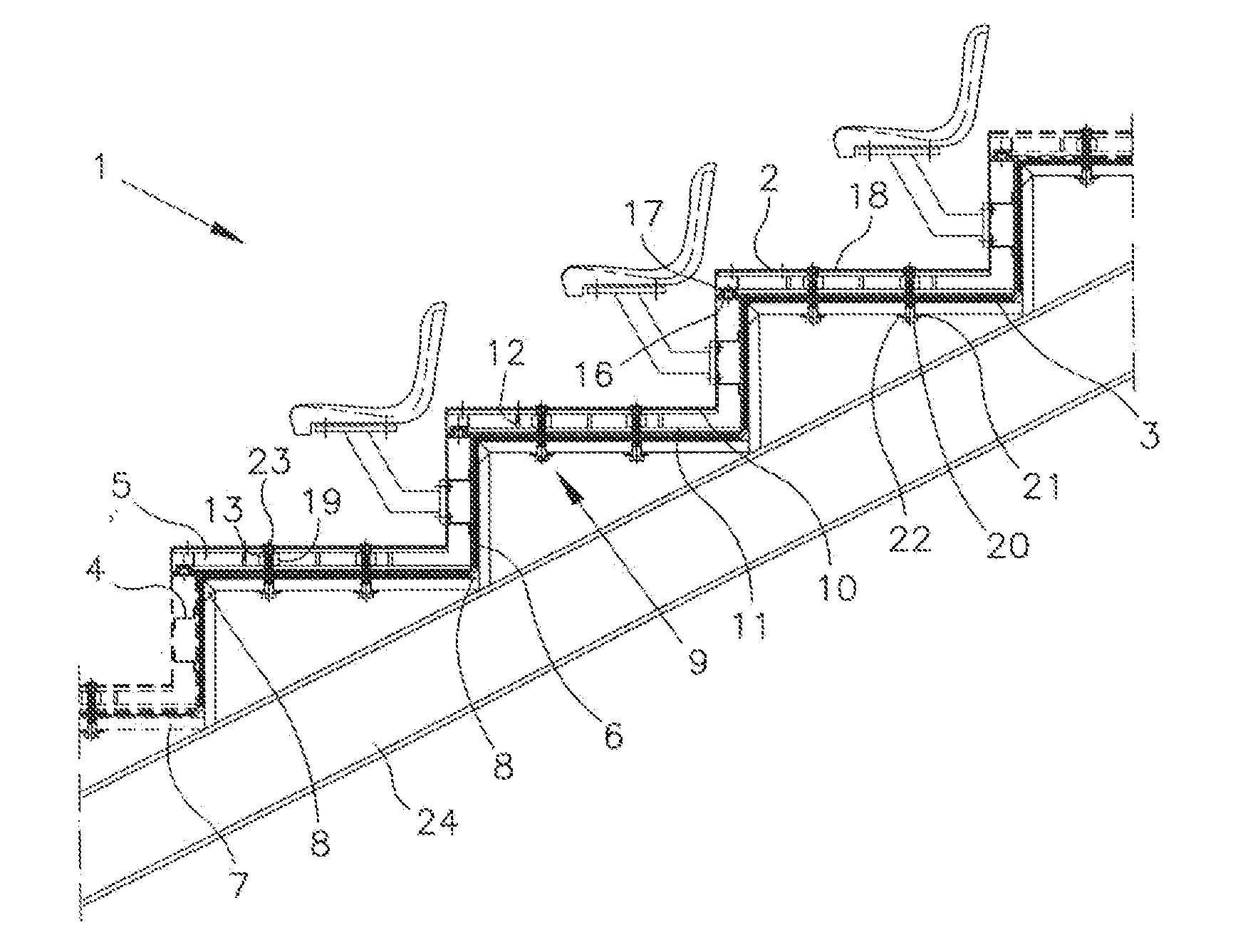

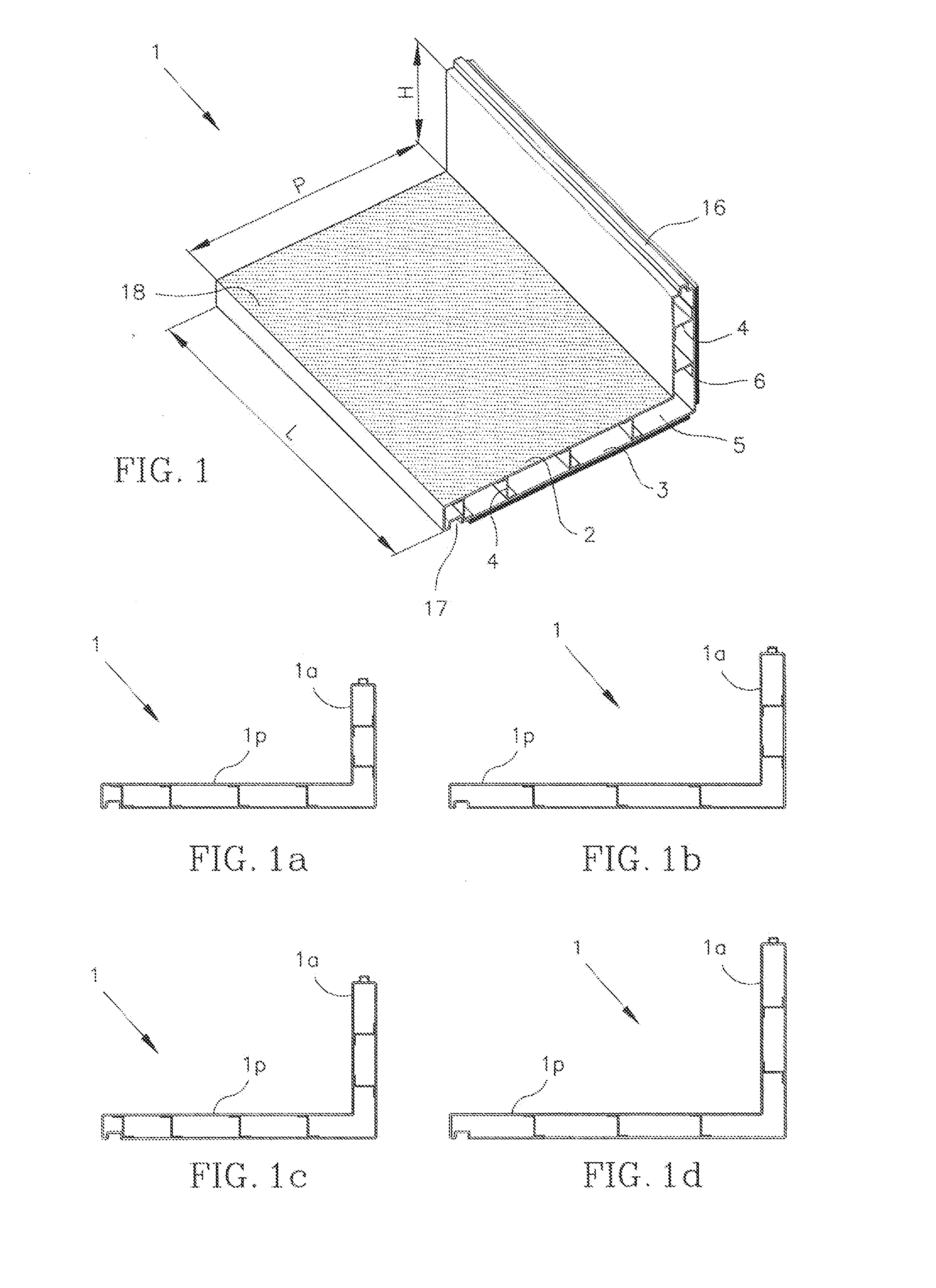

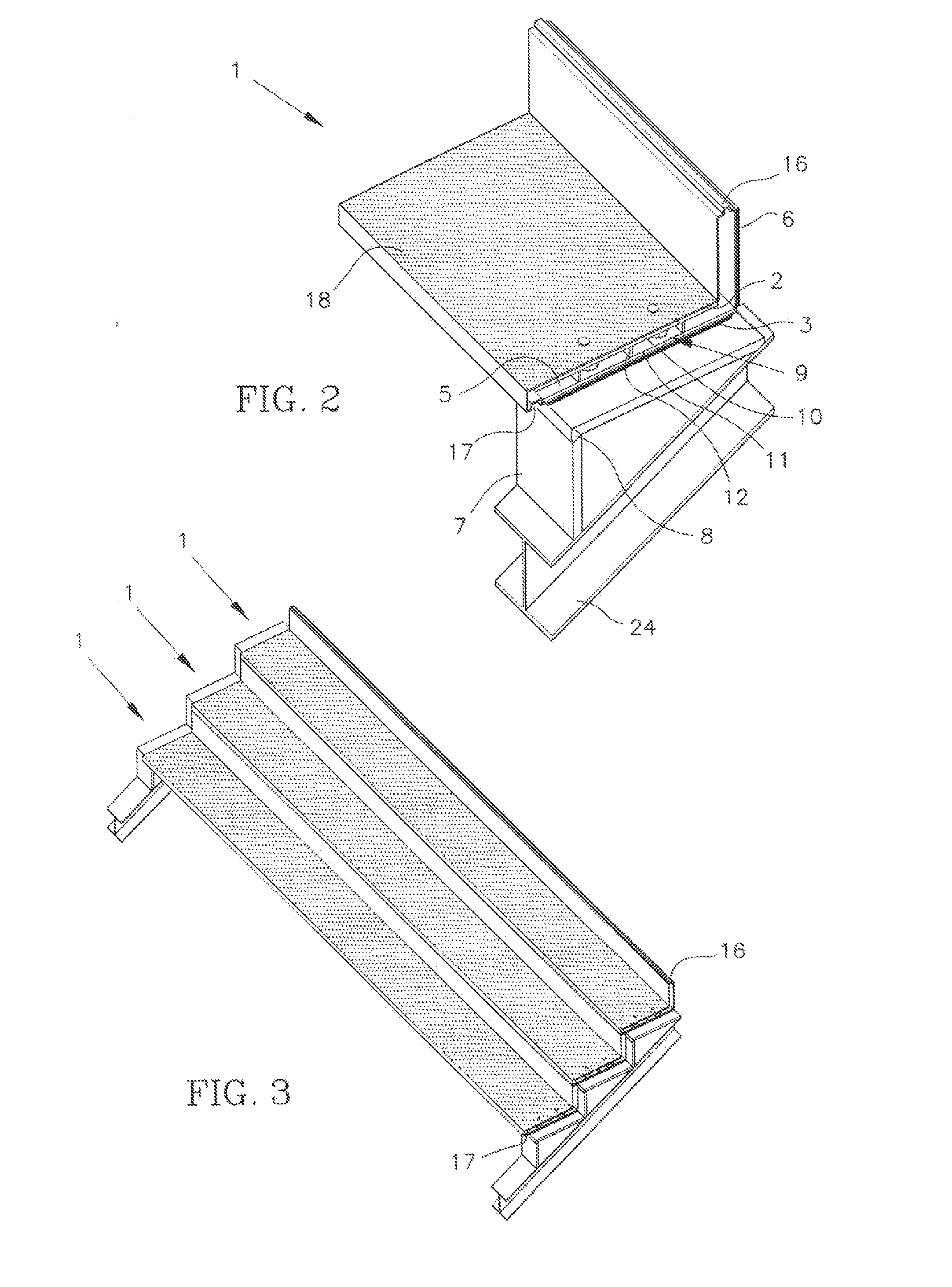

[0030]In FIGS. 1 and 1a to 1d the component according to the embodiment of the present invention represented therein is identified by the reference number 1. Said component 1 comprises a tread portion 1p and a riser portion 1a mutually positioned so as to give the component or module 1 a shape (cross section) like a L. The component 1 has a whole length L, a tread depth P and a riser height H. The component 1 is composed by the combination of an upper plate or foil 2 and a lower plate or foil 3. For example, according to the needs and / or circumstances, the upper and lower plates 2 and 3 can derive from, for example die-bent or zinc-coated, sheet coils the thickness thereof can be chosen according to the needs and / or circumstances, in particular according to the stiffness which one wants to confer to the component and depending upon the whole length L of the component itself. For example, the thickness of the upper and lower plates 2 and 3 can be equal to 30 / 10 mm. The upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com