Centrifugal refrigerant vapour compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

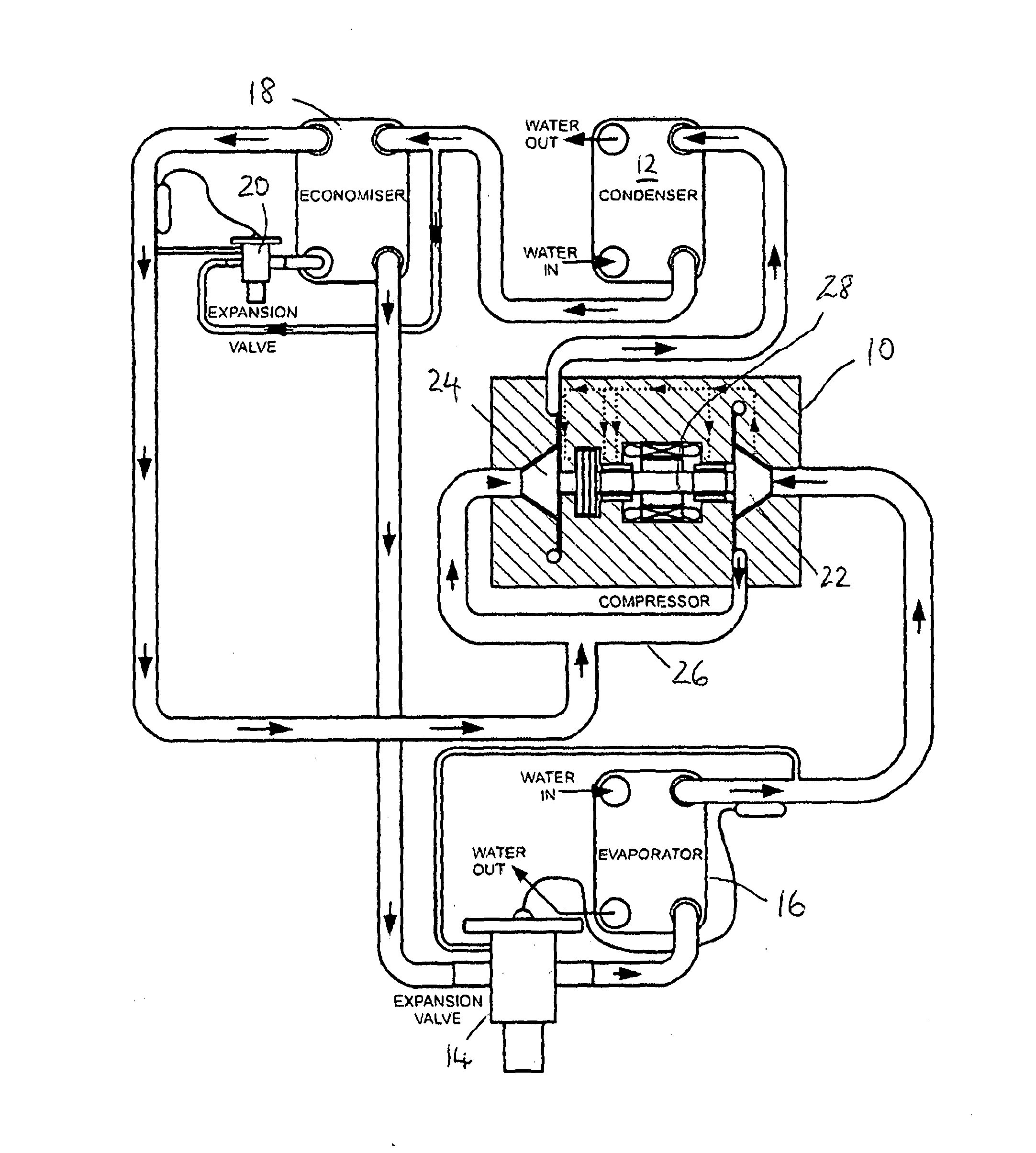

[0104]FIG. 3 shows a refrigeration circuit in accordance with an embodiment of the present invention that might be used, for example, to generate chilled water for a building air conditioning system. In a preferred form, the operating parameters of the system might be designed to provide sufficient heat output to heat a supply of low pressure hot water for the building, in addition to the chilled water for the air conditioning system.

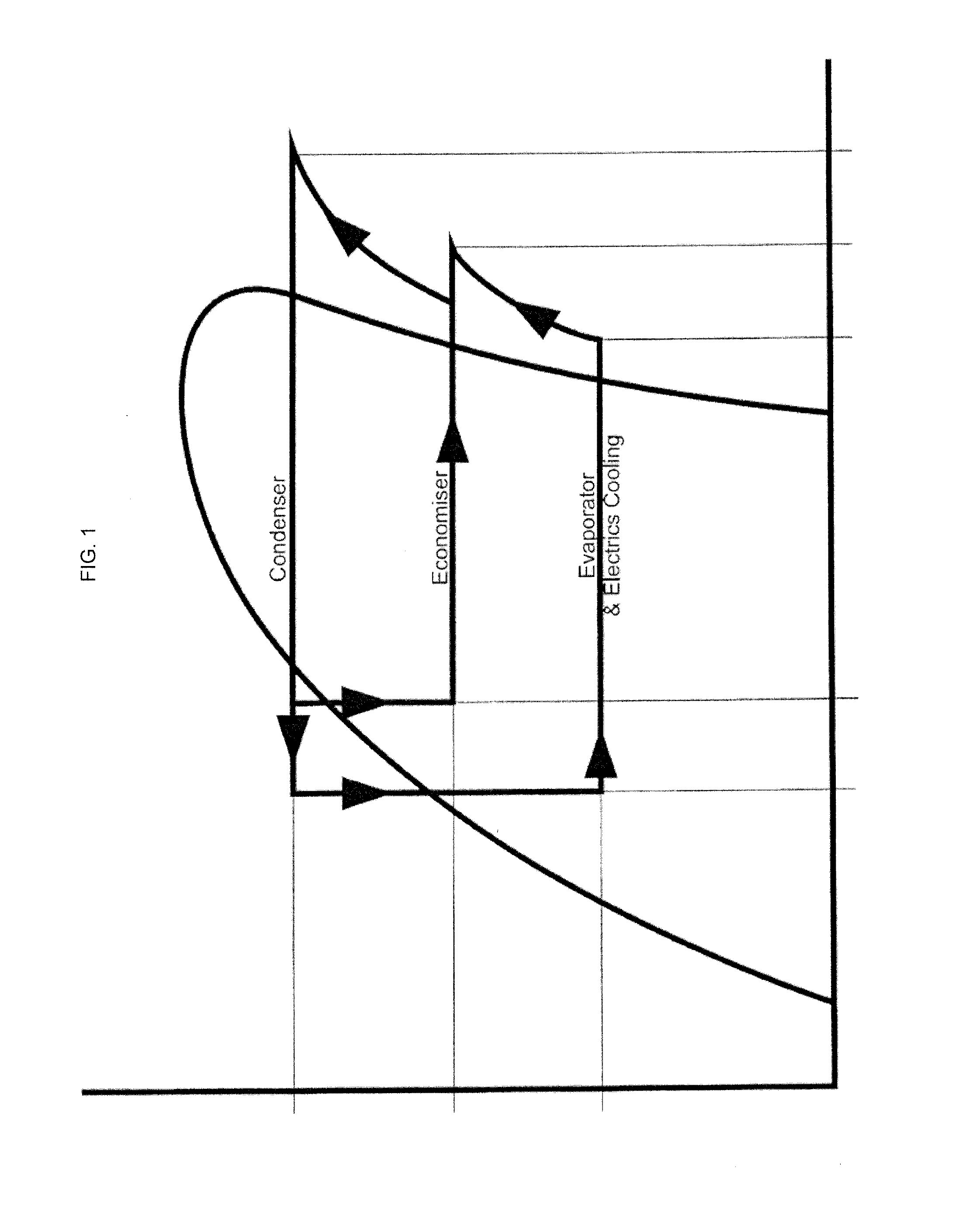

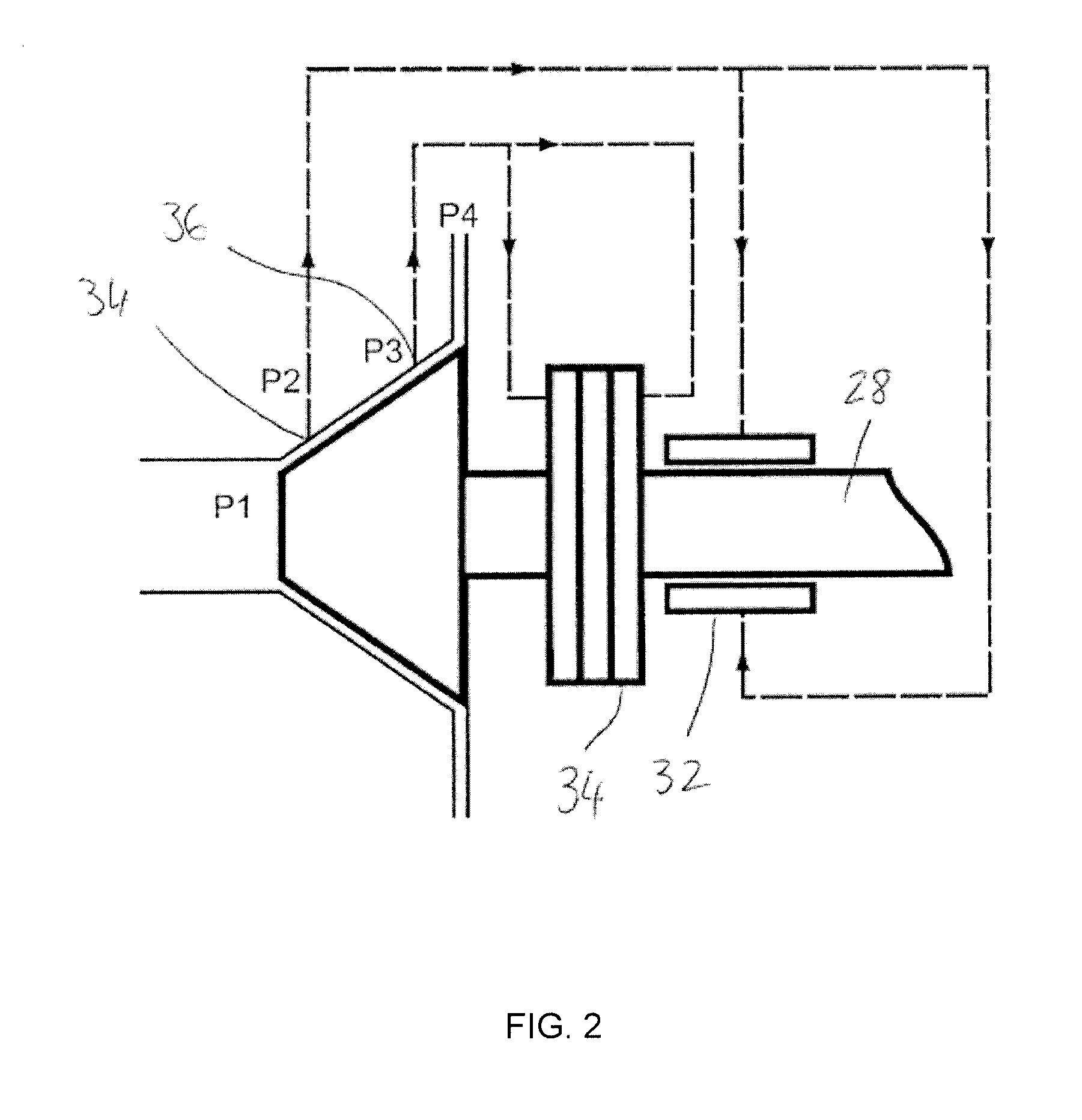

[0105]A refrigerant fluid circulates around the refrigeration system, which operates on a vapour-compression refrigeration cycle (see FIG. 1). The refrigerant enters a two-stage centrifugal compressor 10 in a superheated vapour state and is compressed, in two steps (lower pressure stage 1 and higher pressure stage 2) to a higher pressure and temperature. Superheated refrigerant vapour from the second stage compressor discharge outlet passes to a condenser 12, where it is cooled, the superheat and latent heat of condensation is removed and the vapour con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com